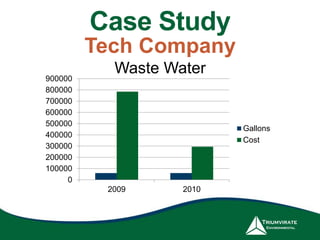

This document summarizes a presentation on consistently reaching waste minimization goals through applying a systematic approach. The presentation recommends assembling a cross-functional waste minimization team, collecting baseline waste data, and building a formal waste minimization program woven into company goals and operations. Applying a systematic approach with goals, engagement, and reporting is key to achieving waste minimization goals consistently over time through continuous improvement.