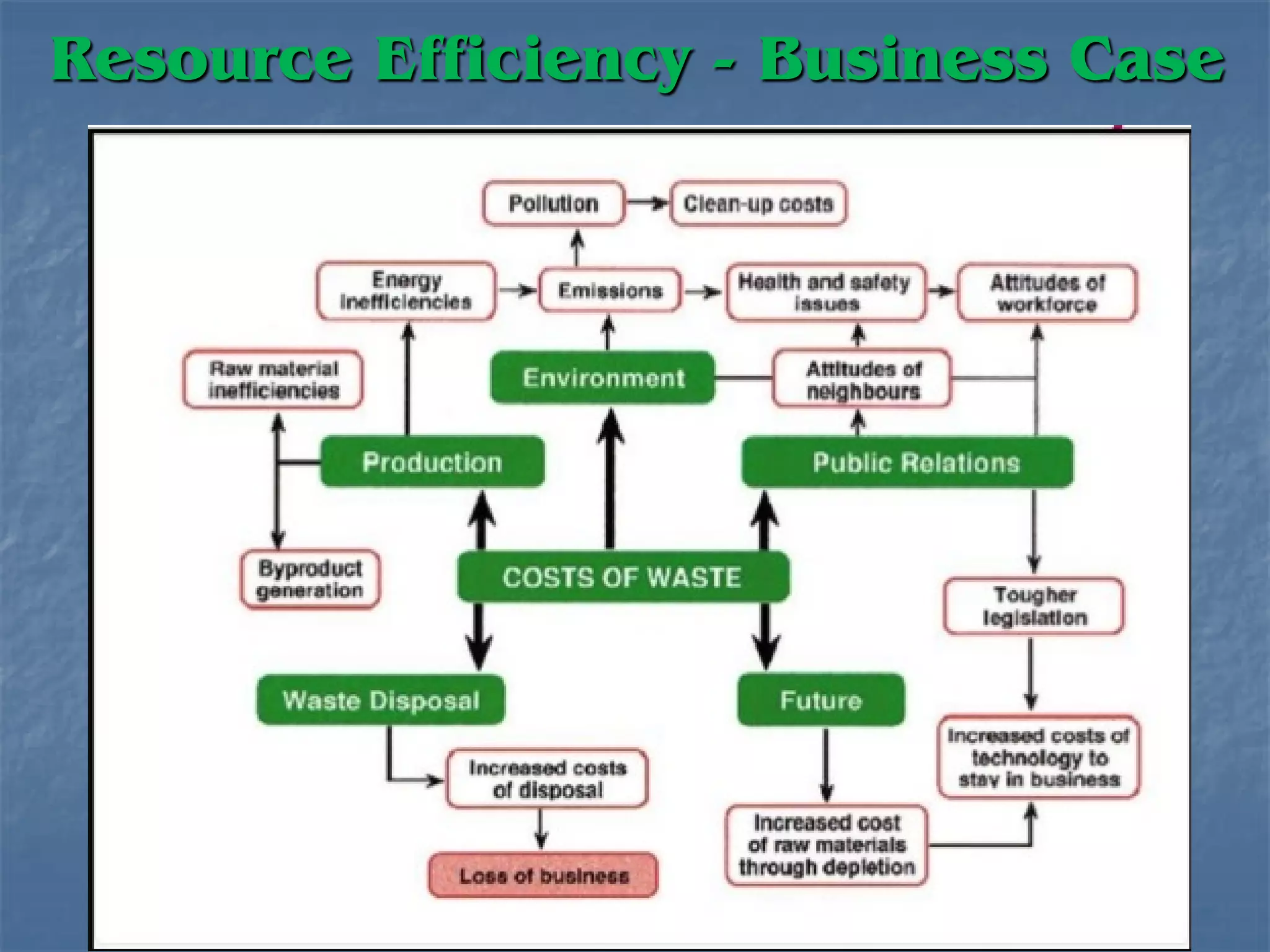

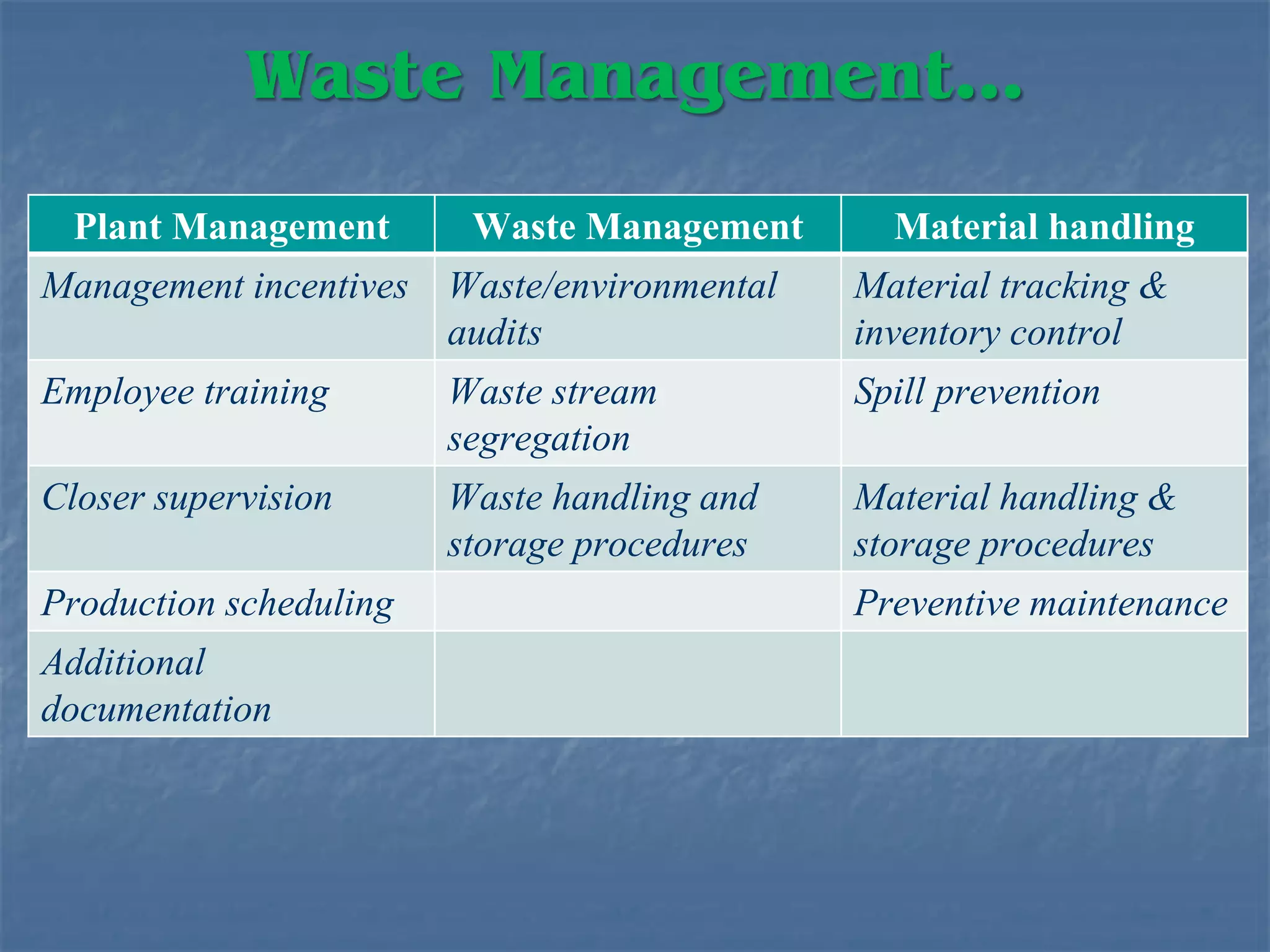

This document discusses waste minimization and environmental imperatives. It defines resource depletion as the exhaustion of resources from a region through overuse beyond replacement rates. Sustainable development is defined as meeting present needs without compromising future generations' ability to meet their own needs. Waste minimization aims to reduce waste production at the societal and individual levels across harvesting, production, distribution, consumption, and disposal. Processes can minimize rejects and maximize outputs, products, and byproducts over inputs like materials, water and energy. Waste minimization provides incentives like reduced costs and improved regulatory compliance and social responsibility. Barriers include economic, technological and regulatory challenges. Conventional waste management focuses on collection, treatment and disposal, while alternative approaches consider