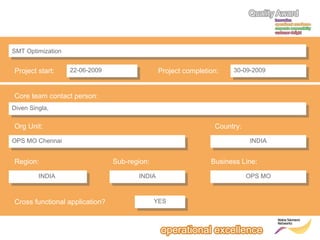

The SMT optimization project aimed to improve equipment utilization from 35% to over 65% for high-value SMT equipment in Chennai, achieving significant results such as cost savings of 336k€ per annum and increased operational efficiency. The project involved setting clear, tangible objectives across six sub-projects, leading to substantial improvements in processes, reduced downtime, and better resource management. The methodologies and best practices developed were shared across teams, influencing further enhancements in future SMT investments.