Embed presentation

Download to read offline

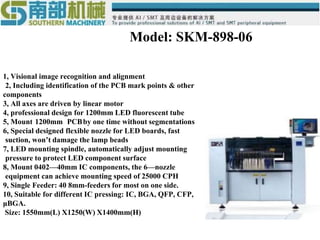

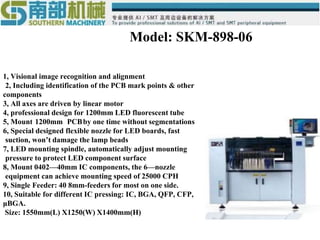

This document summarizes the specifications of an SMT machine model SKM-898-06. It has the following key capabilities: 1. It uses vision recognition for component alignment and identification. 2. It can mount various component types from 0402 to 40mm and place up to 25,000 components per hour. 3. It has dimensions of 1260mm x 1174mm x 1597mm and weighs 828kg. It can handle PCBs from 50mm x 50mm up to 400mm x 500mm.