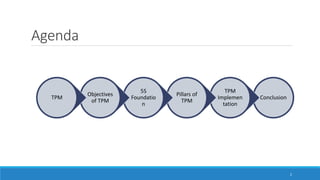

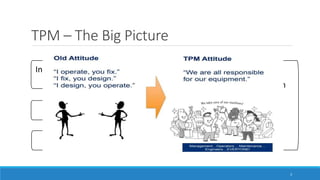

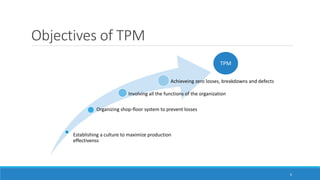

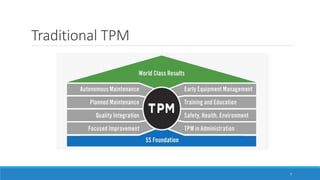

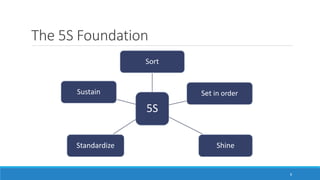

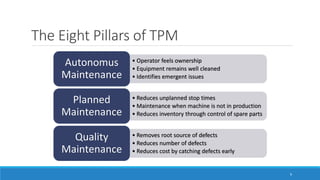

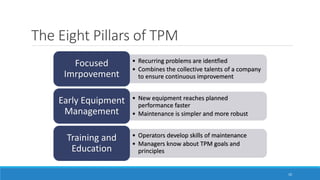

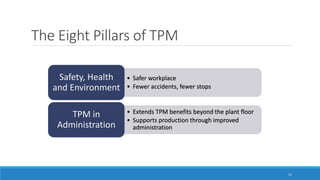

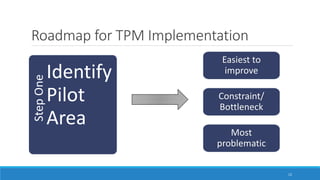

Total Productive Maintenance (TPM) is a lean tool that involves employees in maintaining equipment to improve production through reduced breakdowns and defects. TPM takes a holistic approach to maintenance through a team-based process. The objectives of TPM are to maximize production effectiveness and organize the shop floor to prevent losses. The eight pillars of TPM include autonomous maintenance, planned maintenance, quality maintenance, and training and education. Implementing TPM benefits companies by increasing equipment uptime and plant capacity while lowering costs.