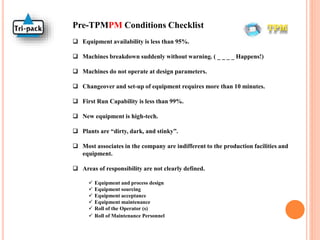

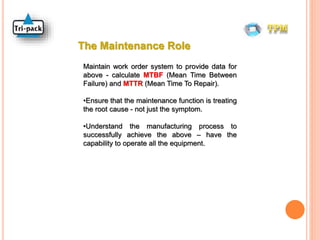

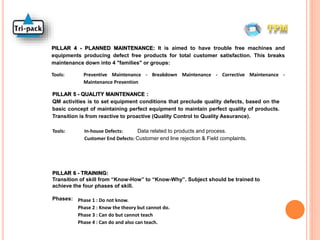

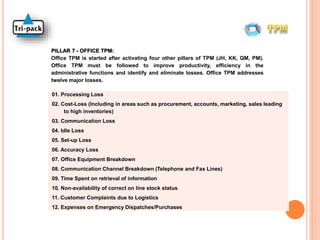

The document provides an overview of Total Productive Maintenance (TPM). It discusses that TPM is a holistic approach to equipment maintenance that aims for perfect production through collaboration between management, operators, and maintenance. The document outlines the 8 pillars of TPM which include techniques like autonomous maintenance, planned maintenance, quality maintenance, and training. It also discusses metrics like overall equipment effectiveness and defines terms like mean time between failures. Overall, the document serves as an introduction to TPM concepts, techniques, and implementation.