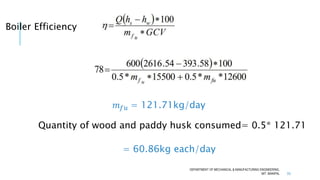

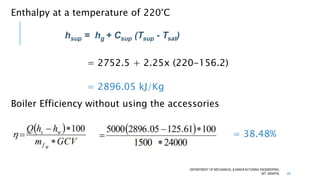

The document provides information on properties of steam including equations to calculate enthalpy of dry saturated steam, wet steam, and superheated steam. It also gives numerical problems involving calculating steam conditions, quality, heat supplied/lost, and boiler efficiency. The problems calculate parameters like enthalpy, dryness fraction, degree of superheat, heat supplied using steam property tables and equations for different steam conditions and processes.

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 7

i) Pressure = 10 bar and T = 200 °C

From steam tables at a pressure of 10 bar

𝑇𝑠𝑎𝑡 = 179.9 °C,

ℎ𝑓 = 762.6 kJ/kg

ℎ𝑓𝑔 = 2013.6 kJ/kg

ℎ𝑔 = 2776.2 kJ/kg

Since the temperature of the steam is greater

than the saturation temperature the steam

sample is superheated [𝑇𝑠𝑎𝑚𝑝𝑙𝑒>𝑇𝑠𝑎𝑡]](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-7-320.jpg)

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 8

Since the temperature of the steam is greater than the saturation

temperature the steam sample is superheated [𝑇𝑠𝑎𝑚𝑝𝑙𝑒>𝑇𝑠𝑎𝑡]

= 2776.2 + 2.25(200 - 179.9)

ℎ𝑠𝑢𝑝= 2821.43 kJ/kg

Degree of Superheat (DOS)

𝐷𝑂𝑆= (𝑇𝑠𝑢𝑝 − 𝑇𝑠𝑎𝑡)](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-8-320.jpg)

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 10

Since enthalpy of dry saturated steam (hg = 2767.4 kJ/kg) is

greater than the enthalpy of steam sample (h = 2500 kJ/kg) the

given sample of steam is wet Steam [ℎ𝑔>ℎ𝑠𝑎𝑚𝑝𝑙𝑒]

X= 0.8693 or 86.93 %

Dryness fraction of the steam (X):

h = ℎ𝑓 + X ℎ𝑓𝑔

2500 = 720.9 + X *

2046.5](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-10-320.jpg)

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 12

Since the temperature of the steam is greater than the saturation

temperature the steam sample is superheated [𝑇𝑠𝑎𝑚𝑝𝑙𝑒>𝑇𝑠𝑎𝑡]

ℎ𝑠𝑢𝑝= 2994.3 kJ/kg

= 2797.2 + 2.25(300 – 212.4)

Enthalpy after heat loss of 400 kJ/kg = 2994.3 – 400

h= 2594.3 kJ/kg](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-12-320.jpg)

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 13

Since the enthalpy after heat loss (2594.3 kJ/kg) is less than the

enthalpy of dry saturated steam (hg = 2797.2 kJ/kg), the steam

is Wet [ℎ𝑔>ℎ𝑠𝑎𝑚𝑝𝑙𝑒]

X= 0.8926 or 89.26%

Dryness fraction of the steam (X):

h = ℎ𝑓 + X ℎ𝑓𝑔

2594.3 = 908.5 + X ×

1888.7](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-13-320.jpg)

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 17

Enthalpy of steam in the main

T=250°C ˃Tsat[212.4°C], steam is superheated

hsup = hg + Csup (Tsup - Tsat)

= 2797.2 + 2.25 (250 –

212.4)

= 2881.8 kJ/kg

Total enthalpy in the main for 2kg of steam

= 2x 2881.8

= 5763.6 kJ/2kg --------(C)](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-17-320.jpg)

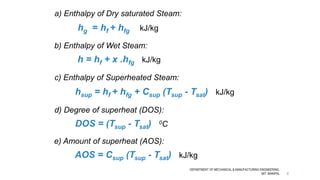

![DEPARTMENT OF MECHANICAL & MANUFACTURING ENGINEERING,

MIT. MANIPAL 30

5] A restaurant, daily uses 600 kg of 95% dry steam produced at a

pressure of 3 bar. The boiler is fitted with an economizer which

increases the feed water temperature to 94° C and is fired using

wood and paddy husk in equal proportions. The gross calorific

values of wood and paddy husk are 15500 kJ/kg and 12600 kJ/kg

respectively. The boiler has been operating with an average

efficiency of 78%. Calculate the daily consumption of wood and

paddy husk?

Data:](https://image.slidesharecdn.com/numericals-240313142611-1fa53569/85/Numericals-pptx-30-320.jpg)