Lab 1 the dryness fraction of the steam(mech)

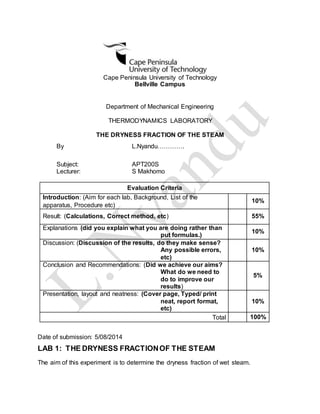

- 1. Cape Peninsula University of Technology Bellville Campus Department of Mechanical Engineering THERMODYNAMICS LABORATORY THE DRYNESS FRACTION OF THE STEAM By L.Nyandu…………. Subject: APT200S Lecturer: S Makhomo Evaluation Criteria Introduction: (Aim for each lab, Background, List of the apparatus, Procedure etc) 10% Result: (Calculations, Correct method, etc) 55% Explanations (did you explain what you are doing rather than put formulas.) 10% Discussion: (Discussion of the results, do they make sense? Any possible errors, etc) 10% Conclusion and Recommendations: (Did we achieve our aims? What do we need to do to improve our results) 5% Presentation, layout and neatness: (Cover page, Typed/ print neat, report format, etc) 10% Total 100% Date of submission: 5/08/2014 LAB 1: THE DRYNESS FRACTIONOF THE STEAM The aim of this experiment is to determine the dryness fraction of wet steam.

- 2. 1. Apparatus Steam boiler plant. Combined Separating and throttling calorimeter. Measuring beaker Thermometer Figure 1: The figure above shows the apparatus for conducting the dryness fraction lab. 2. Theoreticalbackground If we have steam that is nearly dry, we make use of a throttling calorimeter. This calorimeter is operated by first opening the valve opening the stop valve fully so that the steam is not partially throttled as it passes though the valve. The steam then passes through the apparatus for a while to allow the pressure and temperature to stabilize. If the pressure is very close to the atmospheric pressure, the saturation temperature should be around 100 degrees Celsius. It may be assumed that the steam is to be superheated if the temperature somewhere above 100 degrees Celsius. When the conditions are steady, the gauge pressure before throttling is read from the pressure gauge. After throttling, the temperature and the gauge pressure are read from the thermometer and a manometer respectively. The baric pressure is also needed. Suppose M kg of wet steam with a dryness fraction of x enters the separating calorimeter. The vapor part will have a mass of x M kg and the liquid part will have a mass of M kg. In the separating calorimeter part of the liquid, say1 kg will be separated Condenser Separating Calorimeter Throttling calorimeter Separated water Scale Measuring beaker

- 3. from the wet steam. Hence the dryness fraction of the wet steam will increase to x1 which will pass through the throttling process valve. After the throttling process the steam in the throttling calorimeter will be in superheated state. 3. Procedure Start the boiler and supply steam to the separating and throttling calorimeter unit. Start the cooling water flow through the condenser. Open steam valve and allow the steam to flow through the calorimeters to warm through the steam. Open the throttle valve and adjust to give a pressure at exhaust of about 5cm Hg measured on the manometer Drain the separating calorimeter. Start the test and take readings at 2-3 minutes intervals. When a reasonable quantity of condensate is collected measure the quantity of separated water and the quantity of condensate. 4. Results Determine the Absolute Pressure: 𝑃 𝑎𝑏𝑠 = 𝑃𝑔 + 𝑃 𝑎𝑡𝑚 =740 + 101 = 841.33 𝐾𝑃𝑎 ∴ 𝑃1= 841.33 KPa and 𝑃2= 30 KPa ∴ 𝑇1= 112.5 ℃ and 𝑇2= 69.06 ℃ The above written values were calculated using interpolation method and values from the steam tables. Separating calorimeter only (xo): M 𝑺 = 2500m𝑙

- 4. = 2,5𝑙 = 2,5𝑘𝑔 M 𝒘 = 400m𝑙 = 0,4𝑙 = 0,4 𝑘𝑔 𝑋1 = Ms Ms + Mw = 2,5 2,5+0.4 = 0.862 Throttling calorimeter only x1 ℎ2 = ℎsup @ 30 𝐾𝑃𝑎,151℃ ( 𝑢𝑠𝑖𝑛𝑔 𝑑𝑜𝑢𝑏𝑙𝑒 𝑖𝑛𝑡𝑒𝑟𝑝𝑜𝑙𝑎𝑡𝑖𝑜𝑛) = 2783,54 𝐾𝐽/𝑘𝑔 ℎ 𝑓 𝑎𝑛𝑑 ℎ 𝑓𝑔 @ 𝑃1 (Using interpolation) ℎ 𝑓 @ 𝑝1 = 730.027 𝐾𝐽/𝐾𝑔 ℎ 𝑓𝑔 @ 𝑝1 = 2040,309 𝐾𝐽/𝐾𝑔 ℎ 𝑠𝑢𝑝 = ℎ 𝑓 + 𝑋2 . ℎ 𝑓𝑔 𝑋2 = ℎ 𝑠𝑢𝑝−ℎ 𝑓 @ 𝑝1 ℎ 𝑓𝑔 @ 𝑝1 𝑋2 = 2783,54−730,027 2040,309 ∴ 𝑋2 = 1.0064 This means it lies outside the dome to the superheated region. ∴ 𝑋0 = 𝑋1 × 𝑋2 = 0,862 × 1,0064 = 0,867 ∴ 𝑋0 ≈ 0,87 Readings taken from experiment: Reading Units Volume of Steam (Vs) 0.0025 m3

- 5. Volume of Water (Vw ) 0.0004 m3 Pressure before throttling (P1) 840 kPa Pressure After throttling (P2) 30 kPa Temperature of steam before throttling (t1) 112,5 oC Temperature of steam After throttling (t2) 69,06 oC Figure 2: The table above shows the experimental readings that were recorded for the dryness faction lab conducted. 5. Discussion Based on the results of the readings we obtained when conducting the experiment in the lab, it can be said that using the readings that were recorded in the lab, the dryness fraction of the steam could be found in regards with the use of the theoretical equations from the thermodynamics textbook. From the results obtained, the dryness fraction is 0.862 at x0 this showed us that at that point in time the steam is 87% dry and 13% wet. We got 1.0064 at x1 so that showed us that the steam is superheated because it is greater than 1 at that point so the combined separating and throttling calorimeter’s dryness faction was found by using the equation where both x0 and x1 were multiplied to get 0.87. This shows that the state of the steam is still wet because the value of the dryness fraction of steam is less than 1. 6. Conclusion It can be concluded that the experiment was successful and the dryness fraction of the steam was found using the readings found to be 0.95 which then showed us that the steam state is considered wet. 7. Recommendations Maintenance in the laboratory apparatus for the dryness fraction lab conduction should be done before students are allowed to go and do the experiments. This is due to varying data or reading that student get when conducting the labs as that would make lecturers to mark the laboratory work easier. That could also constitute to the improvement on the efficiency of the set of apparatus as seen above calibration. 8. BIBLIOGRAPHY J.A. Leach. 2007. “Engineering thermodynamics’. Chapter 8: Juta publishers, Cape town, South Africa.