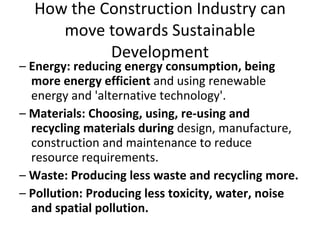

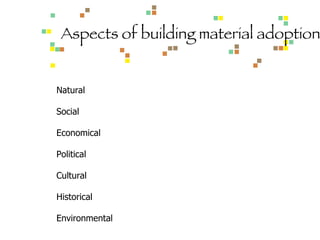

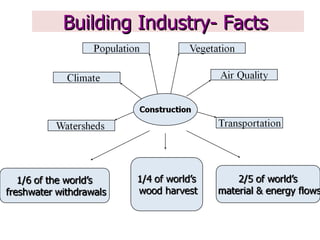

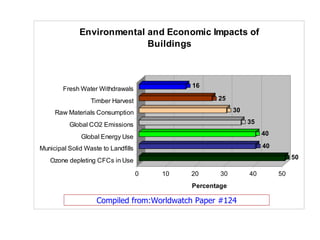

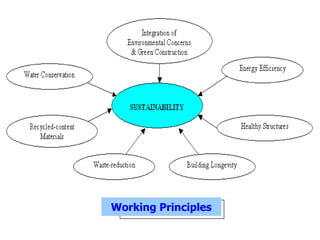

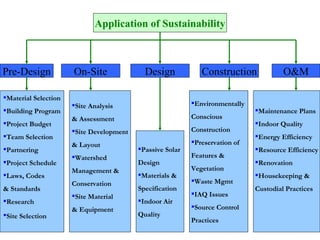

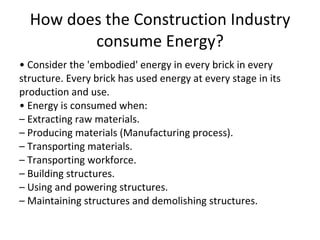

The document discusses sustainability and natural resource management in the construction industry. It outlines how construction activities have negatively impacted the environment through pollution, waste, and overuse of resources. It then discusses how the industry can move toward more sustainable practices such as reducing energy and material consumption, reusing and recycling resources, and producing less waste and pollution. Specific sustainable strategies are provided for material selection, site development, construction practices, and building operation and maintenance.