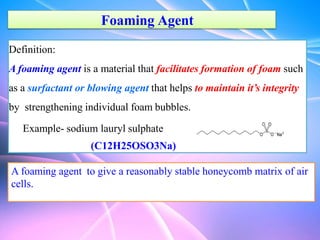

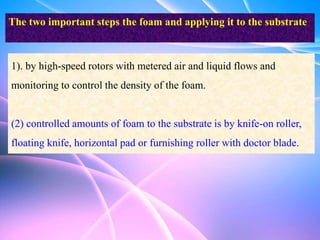

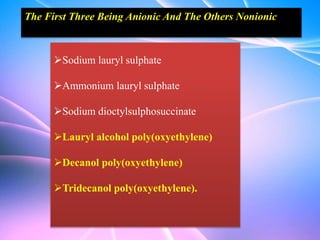

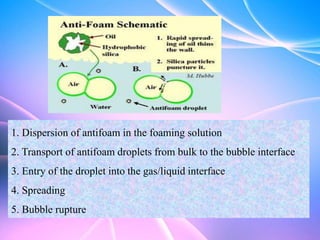

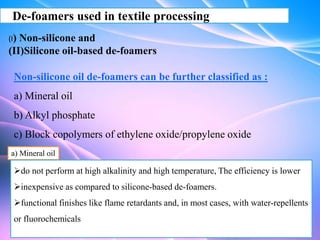

This document discusses foaming and de-foaming agents used in textile processing. It defines foaming agents as materials that facilitate foam formation and provide stability, with examples like sodium lauryl sulfate. Foam is applied to textiles using high-speed rotors or coating methods. De-foaming agents destabilize foam through their surface-active properties, with examples being mineral oils, alkyl phosphates, and silicone or non-silicone emulsions. The document outlines the mechanisms and requirements for effective foaming and de-foaming in textile wet processing.