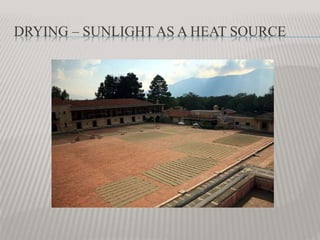

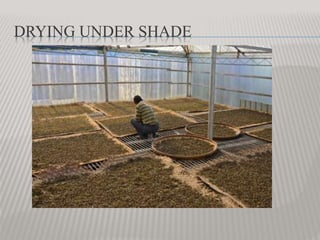

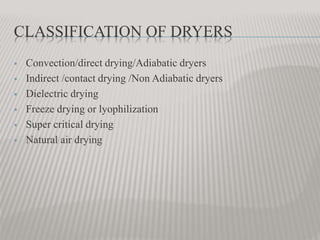

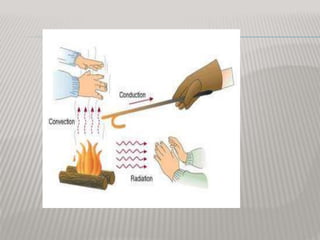

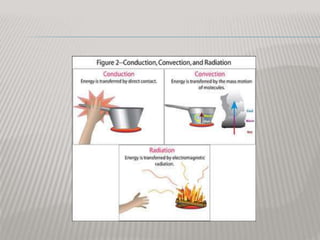

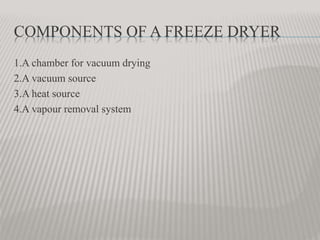

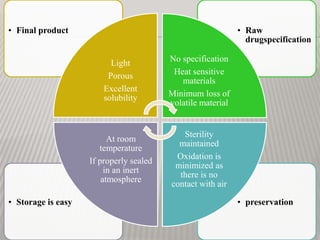

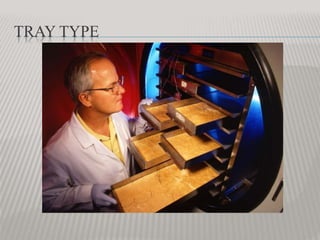

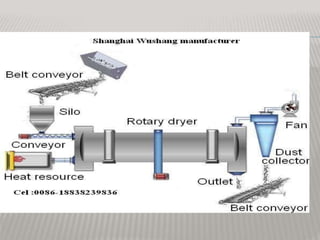

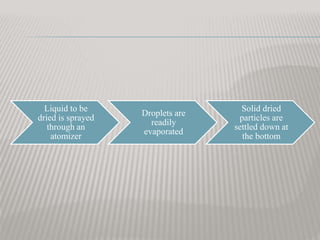

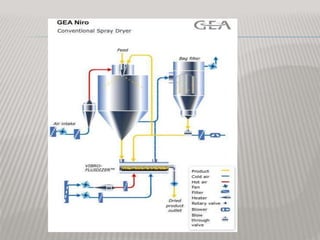

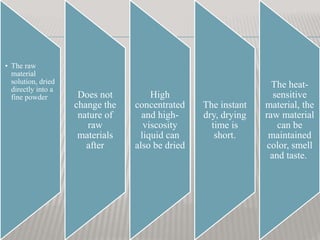

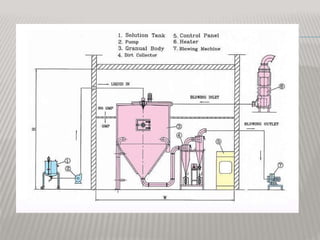

Methods of drying solids involve removing liquid via vaporization with heat. Ancient methods included natural air drying and drying under sunlight or shade. Modern dryers include convection, contact, dielectric, freeze, and supercritical dryers. Selection depends on materials and desired properties. Common dryers are tray, tunnel, rotary, fluidized bed, drum, and spray dryers. Each has advantages like uniformity, energy efficiency, or preserving thermolabile substances. Proper drying is important for storage, preservation, and processing in industries like pharmaceuticals and foods.