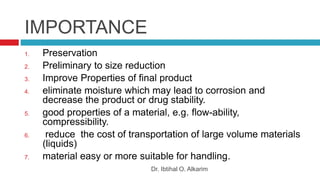

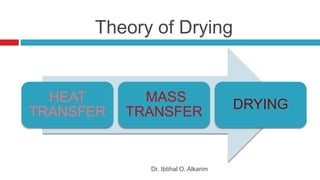

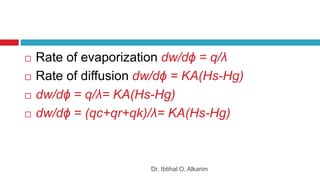

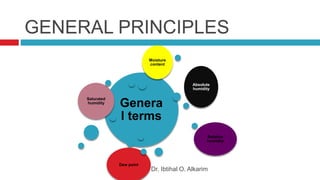

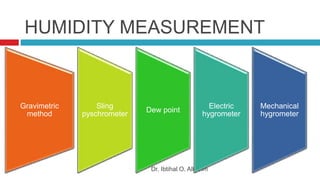

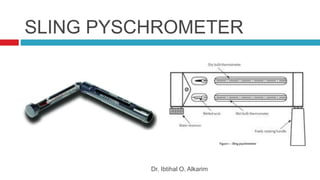

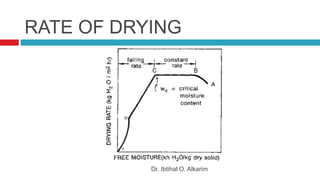

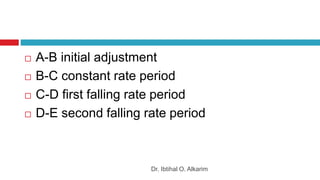

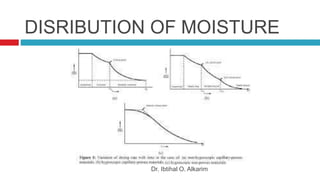

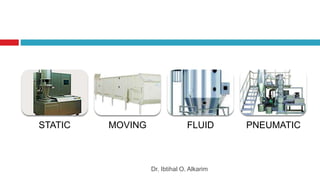

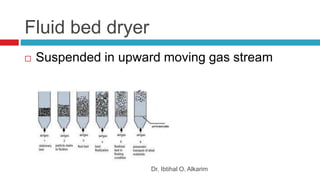

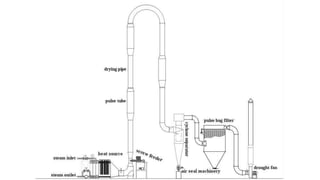

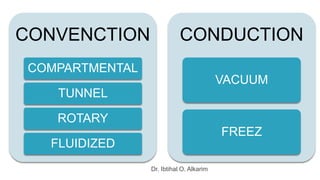

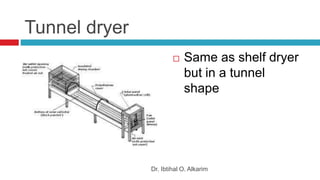

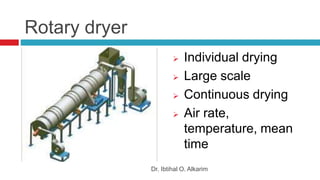

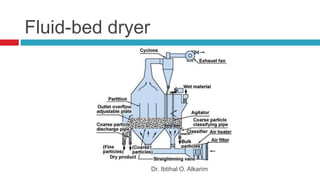

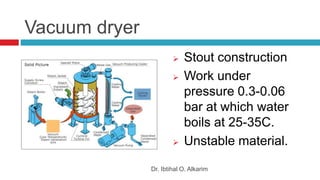

This document discusses various aspects of drying, including definitions, principles, measurement techniques, and classifications. Drying involves the removal of water or liquid from a solid-liquid mixture to form a dry solid, and differs from evaporation which concentrates solutions. Drying is important for preservation, size reduction, improving product properties, and reducing costs. Drying rates can be constant, falling, or in multiple falling periods. Moisture distributes unevenly in materials in different states. Dryers are classified based on solid handling methods (static, moving, fluidized), heat transfer methods (convection, conduction, etc.), and operating principles. Common dryer types include shelf, tunnel, rotary, fluidized bed, vacuum