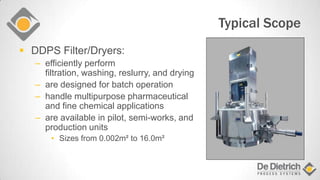

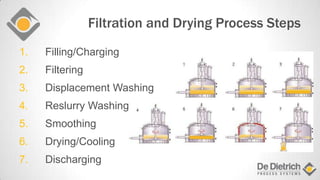

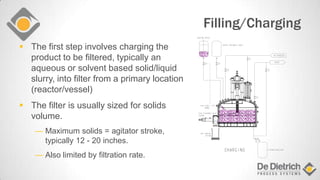

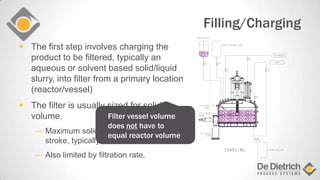

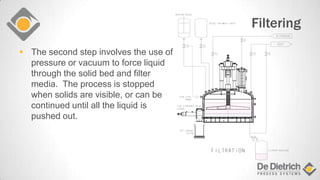

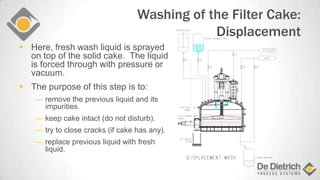

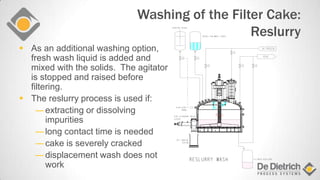

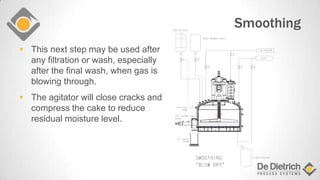

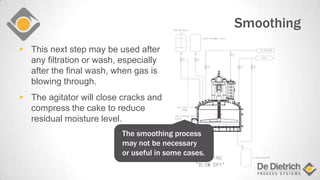

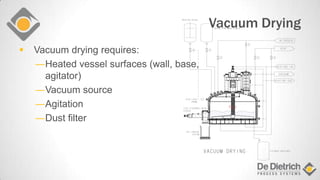

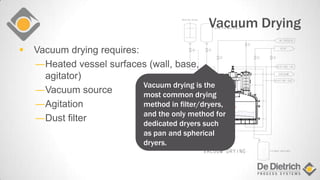

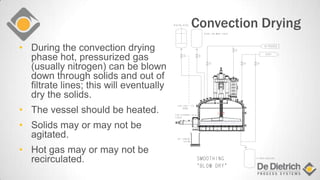

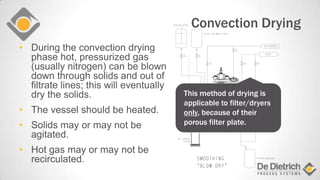

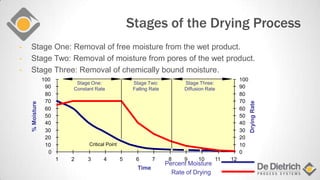

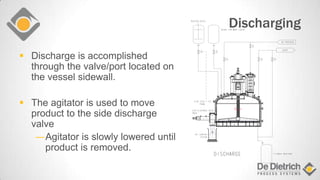

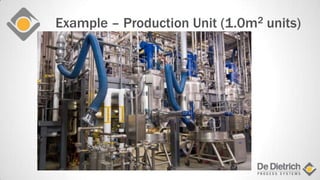

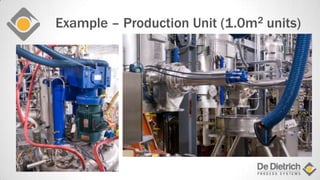

DDPS filter/dryers are batch filtration and drying equipment used in pharmaceutical and chemical applications. They efficiently perform filtration, washing, reslurry, and drying processes. Filter/dryers are available in pilot, semi-works, and production sizes from 0.002 to 16 square meters. Special designs include cGMP, CIP, aseptic, and sterile configurations. The standard filtration and drying process involves filling, filtering, displacement washing, optional reslurry washing, smoothing, drying/cooling, and discharging. Vacuum drying is most common but convection drying is also possible. DDPS offers process engineering support and testing to optimize customers' filtration processes. Filter/dryers provide advantages like enclosure, low maintenance,