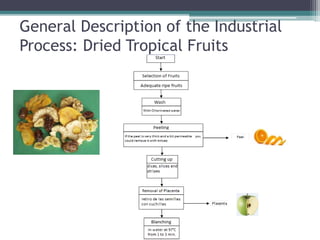

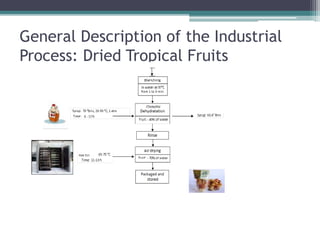

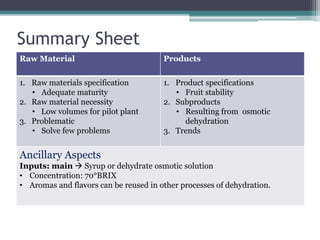

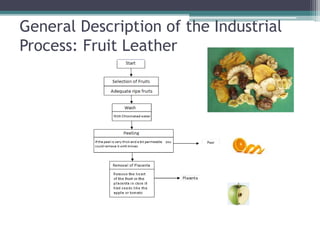

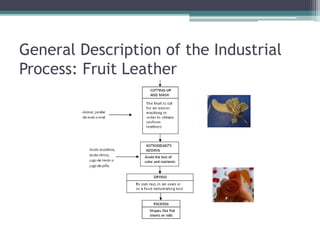

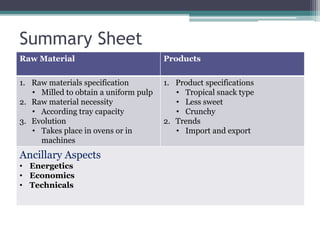

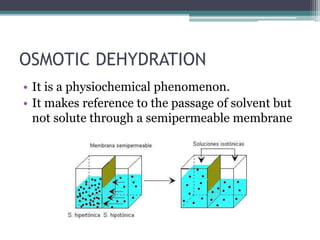

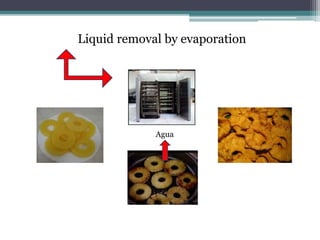

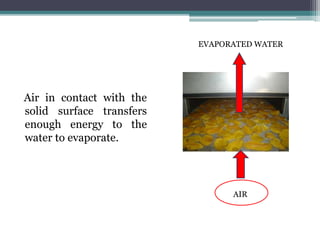

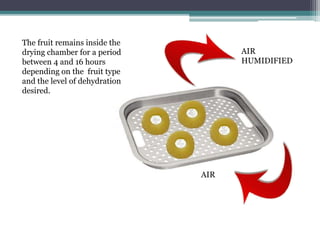

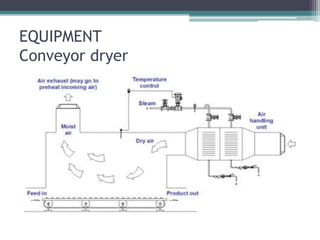

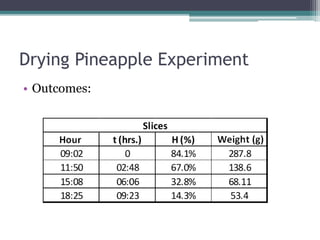

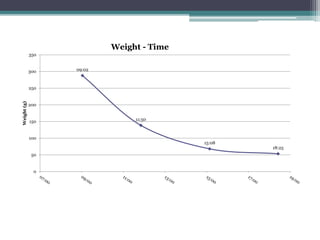

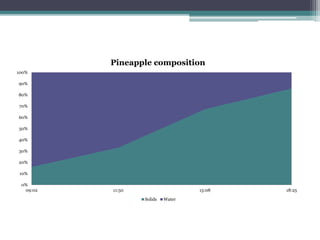

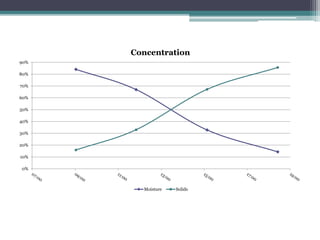

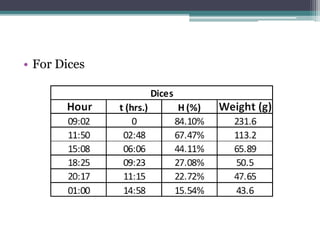

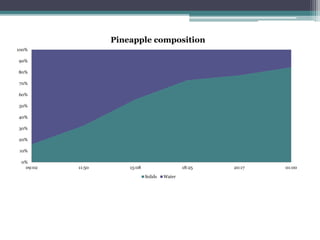

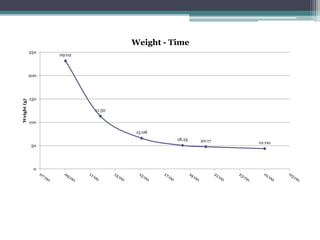

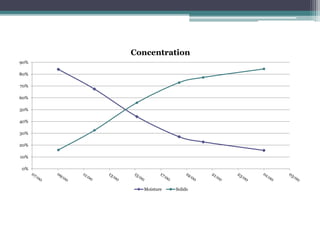

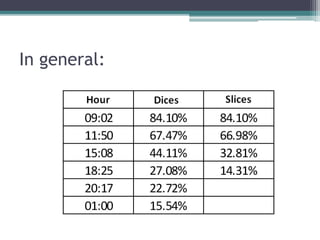

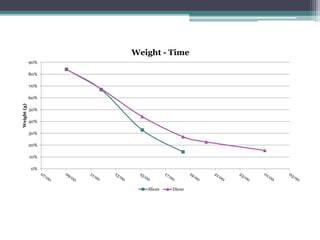

This document provides information about the industrial process for drying tropical fruits. It discusses the raw materials, specifications for dried fruit products, and trends in the market. It also describes the process of osmotic dehydration where fruit is soaked in a syrup solution so that water leaves the fruit and solute enters. Key factors that affect the dehydration speed are also outlined. Finally, it provides examples of equipment used for drying fruits and results from an experiment drying pineapple slices and dices.