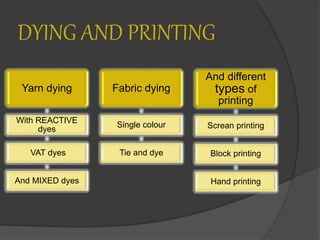

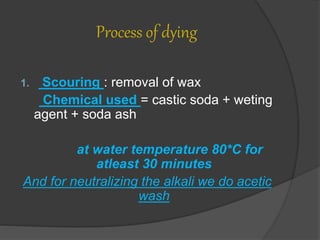

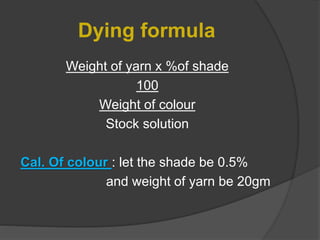

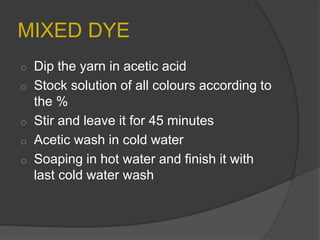

This document provides information about a summer training program at Weavers Center from June 15th to July 15th that focuses on dying, printing, and weaving. It details various dyeing techniques like reactive dyeing, vat dyeing, and mixed dyeing for both yarn and fabric. Specific dyeing processes and formulas are outlined for scouring, bleaching, and applying different types of dyes. Finally, it briefly mentions screen printing, block printing, and hand printing techniques for fabric.