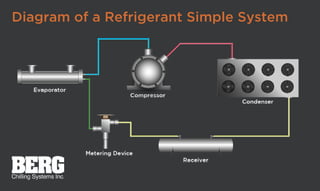

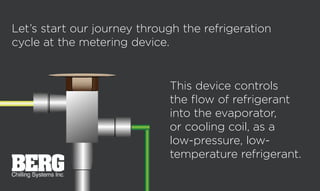

The document discusses the basic components and process of a refrigeration system. It explains that a chiller is a component that removes heat from a process using a refrigeration cycle. The main components of a refrigeration system are an evaporator, condenser, compressor, and metering device connected by tubing. The refrigerant is circulated through this closed loop system, changing states from gas to liquid and back again, in order to transfer heat out of the evaporator and reject it to the condenser. This allows the evaporator to cool the surrounding air or liquid through the refrigeration effect.