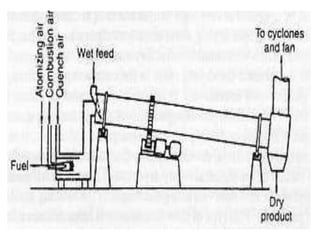

Mr. Debashis Purohit presented on drying technology used in the pharmaceutical industry. He discussed four main drying techniques: fluidized bed drying, drum drying, rotary drying, and lyophilization (freeze drying). For each technique, he covered the principles, working, advantages, disadvantages, and uses. He concluded with two review articles discussing crystallization processes and freeze drying in more detail.

![PRINCIPLES OF DRYING [1]

Large surface area for heat transfer.

Efficient heat transfer per unit area (to supply

sufficient latent heat of vaporization or heat of

sublimation in case of freeze-drying)

Efficient mass transfer of evaporated water

through any surrounding vapour boundary layers,

i.e. sufficient turbulence to minimize vapour

boundary layer thickness.

Efficient vapour removal , i.e. low relative

humidity air at adequate velocity.](https://image.slidesharecdn.com/ppt-180623023846/85/Drying-technology-used-in-Pharmaceutical-Industry-2-320.jpg)

![Different Machinaries used in Pharmaceutical

drying [2]

Fluidized bed drying

Drum dryer

Rotary Dryers

Lyophillization(Freeze drying)](https://image.slidesharecdn.com/ppt-180623023846/85/Drying-technology-used-in-Pharmaceutical-Industry-3-320.jpg)