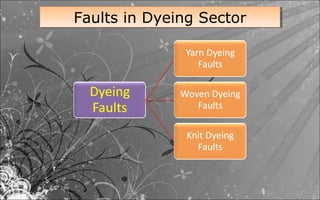

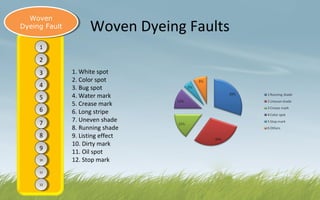

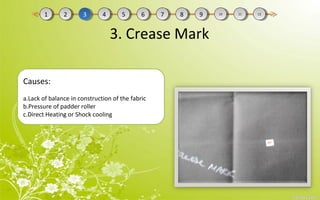

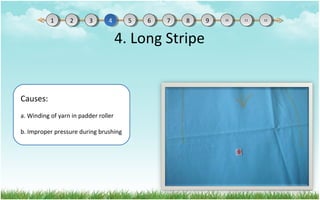

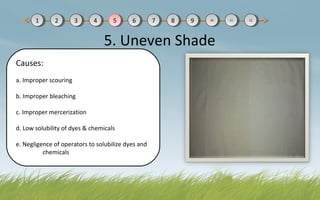

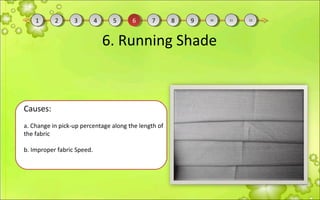

This document discusses common faults that can occur in woven dyeing processes, their causes, and ways to prevent them. It lists 12 common woven dyeing faults including white spots, color spots, crease marks, long stripes, and uneven shades. For each fault, the document describes potential causes such as foreign particles in the fabric or solution, hairiness in the fabric, dye and chemical factors, improper washing, operator negligence, and issues with fabric construction or processing speeds. The document is authored by Mazadul Hasan sheshir from Southeast University's Department of Wet Processing Technology.