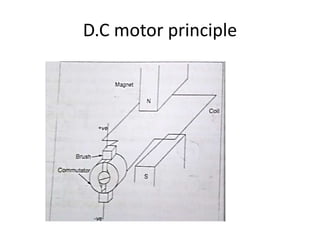

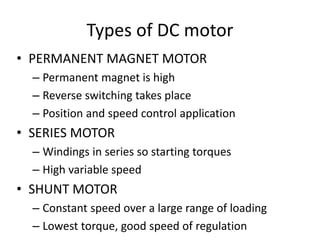

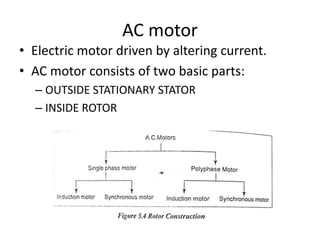

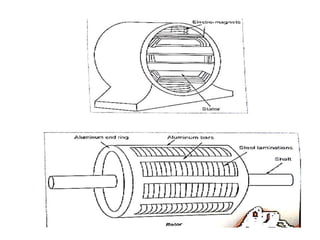

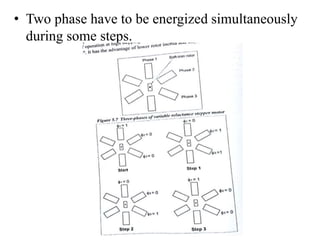

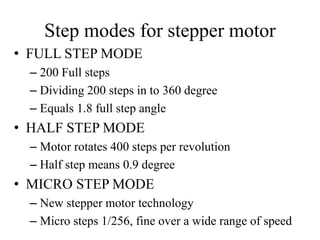

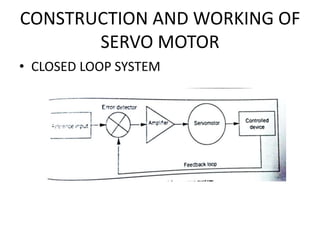

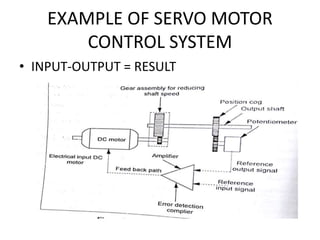

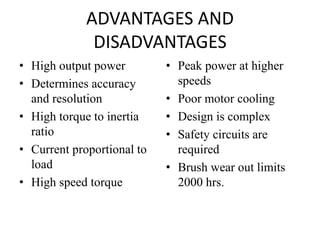

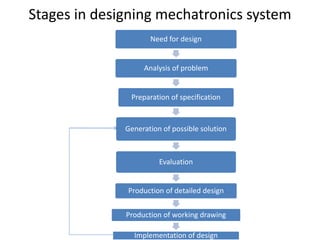

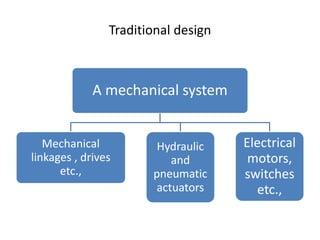

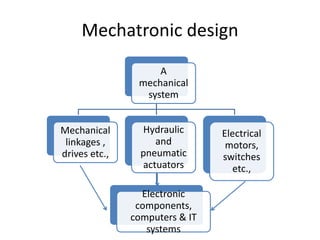

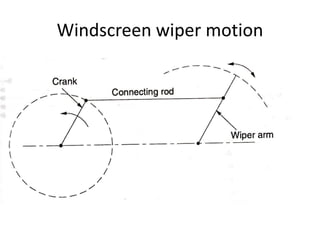

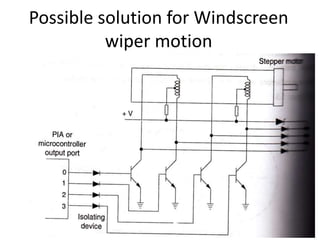

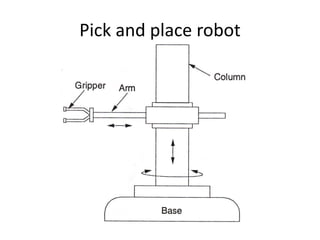

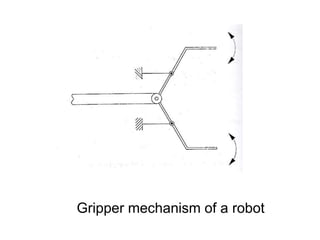

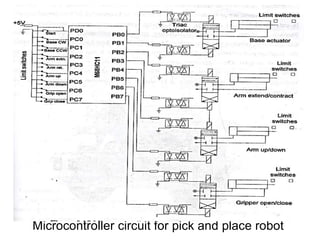

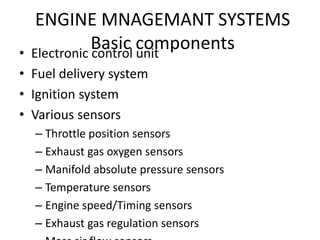

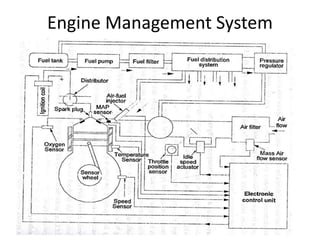

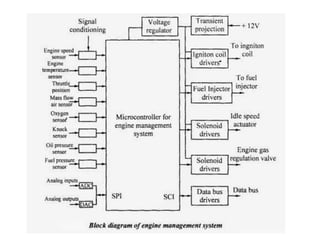

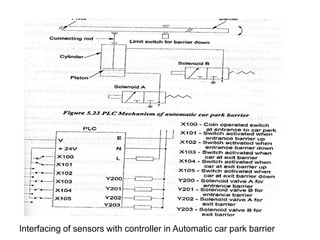

The document discusses various types of actuators and motors used in mechatronics systems design including stepper motors, servo motors, DC motors, and AC induction motors. It describes their working principles and applications. It also outlines the stages of the mechatronics design process from problem analysis to implementation. Examples of mechatronic systems are provided such as a pick and place robot, engine management system, and automatic car park barrier.