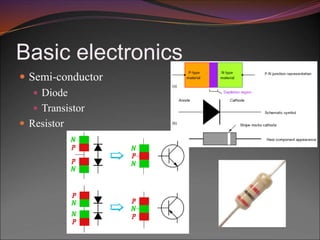

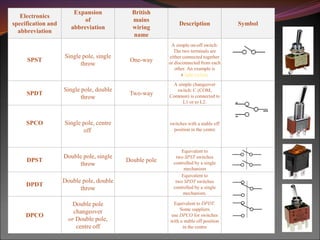

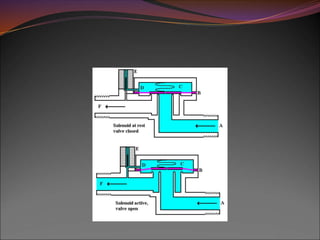

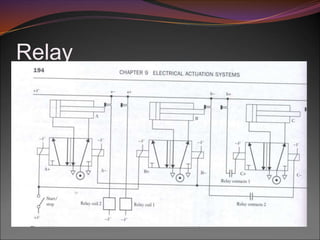

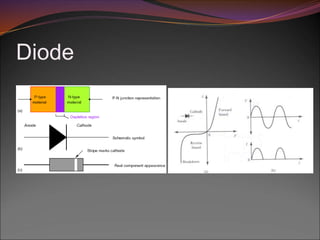

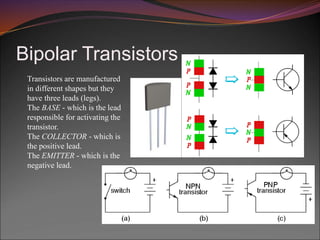

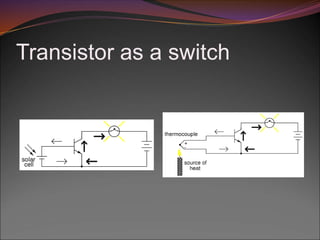

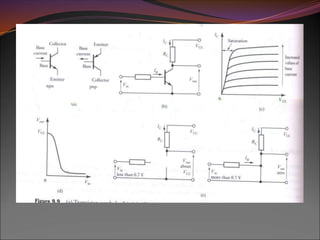

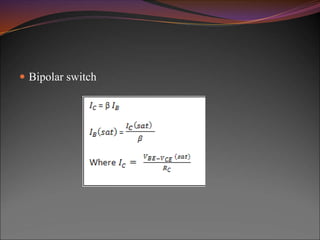

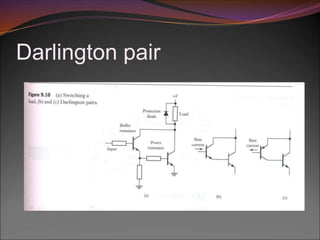

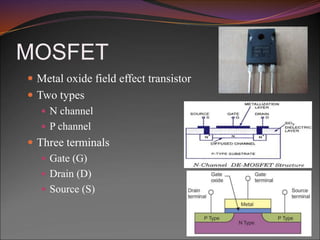

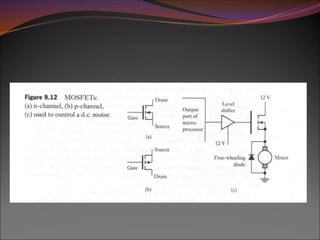

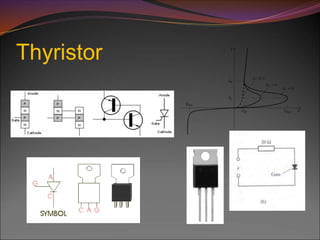

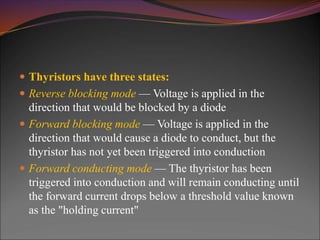

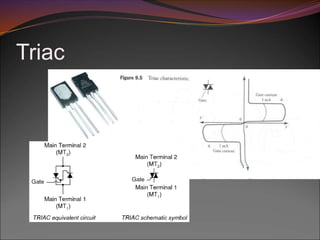

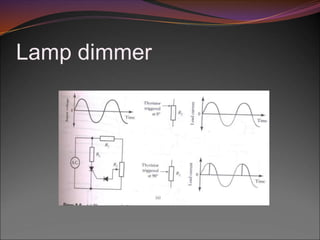

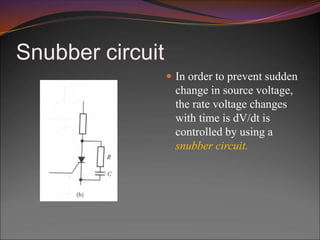

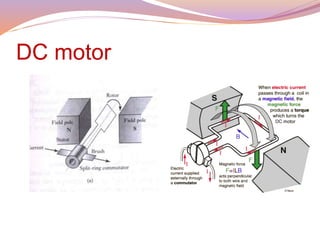

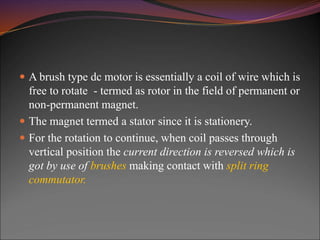

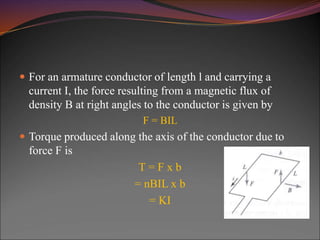

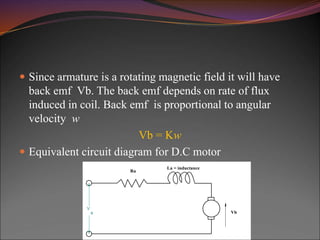

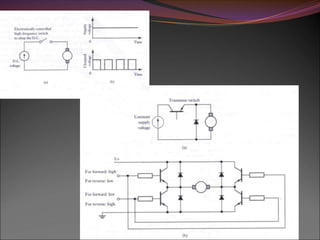

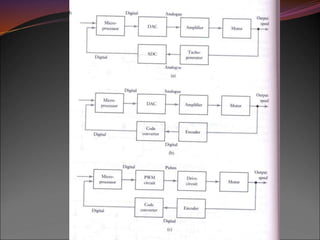

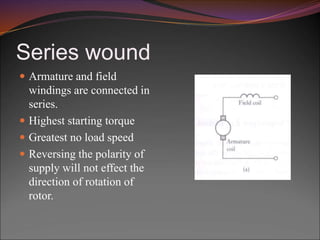

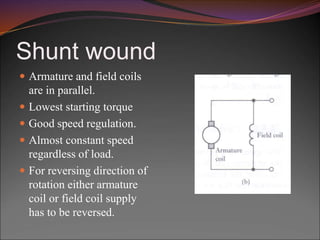

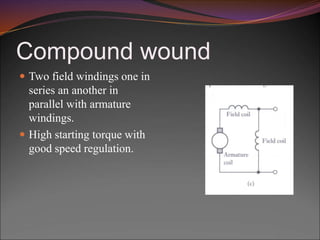

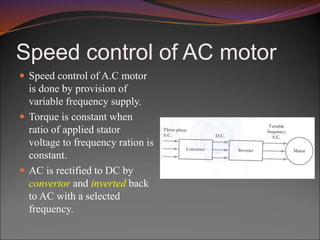

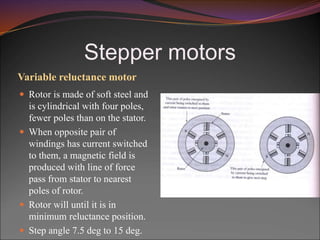

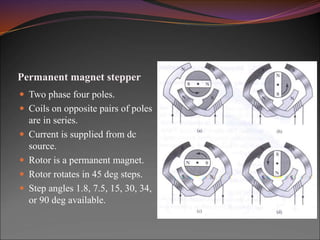

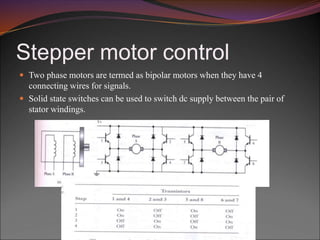

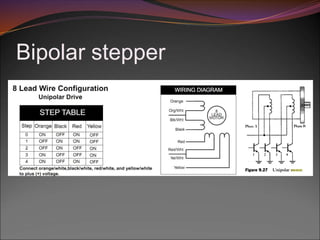

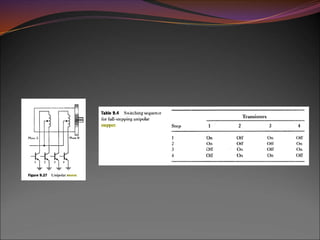

This document provides an overview of different types of actuators and electronic components used in actuator systems. It discusses switching devices like mechanical switches and solid state switches. It also covers solenoids, DC motors, AC motors, stepper motors, and various solid state components like diodes, transistors, thyristors, and MOSFETs that are used to control actuators. Diagrams and explanations of how different actuator components work are provided throughout the document.