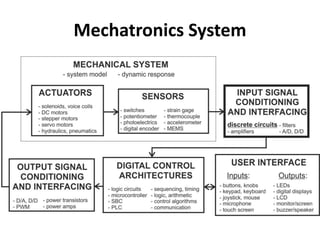

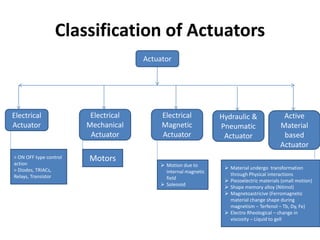

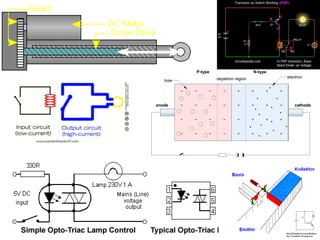

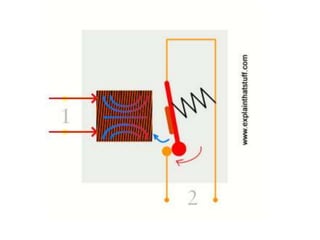

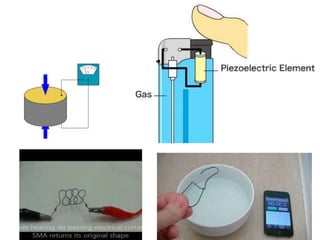

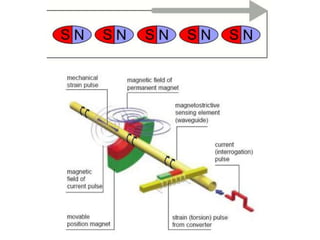

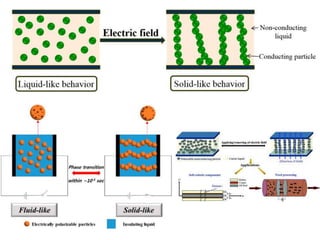

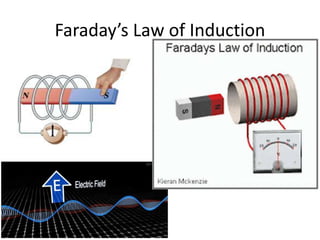

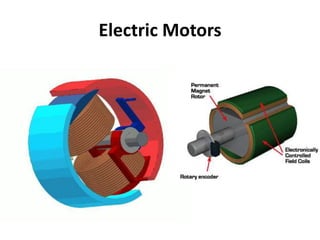

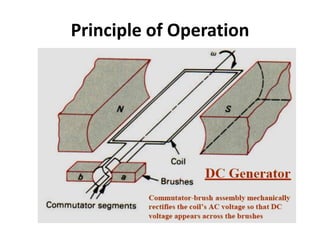

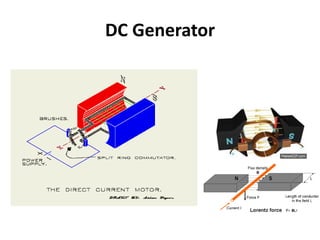

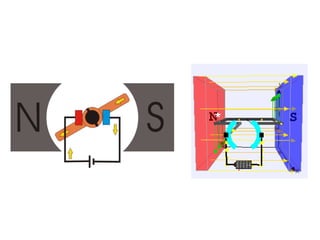

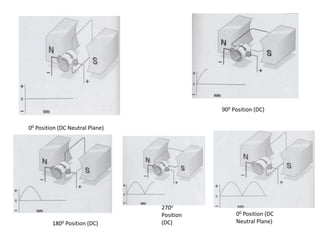

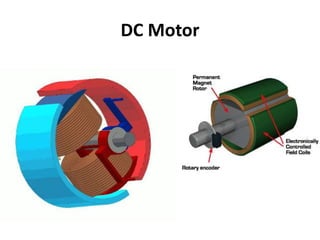

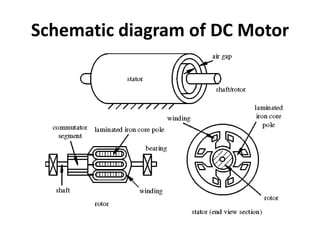

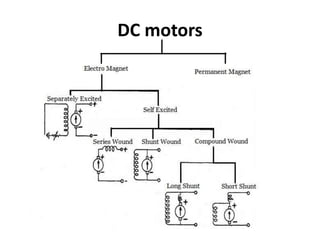

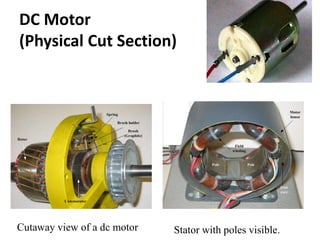

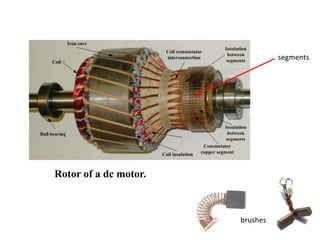

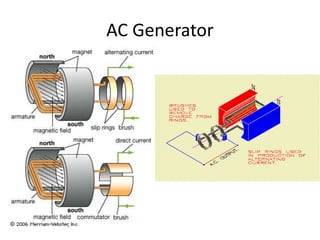

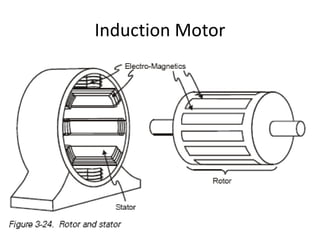

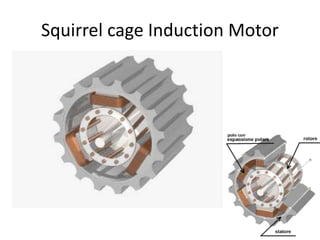

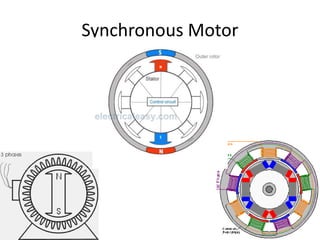

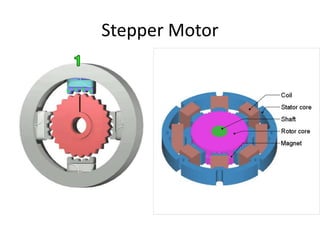

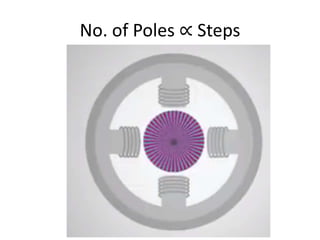

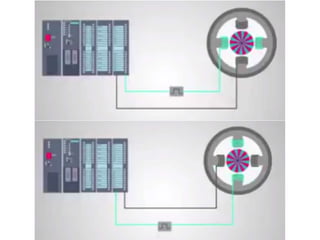

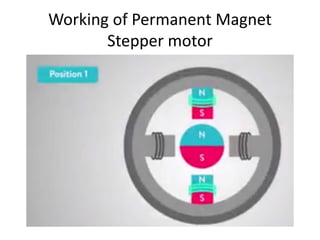

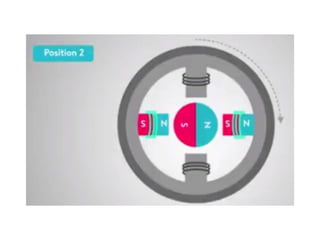

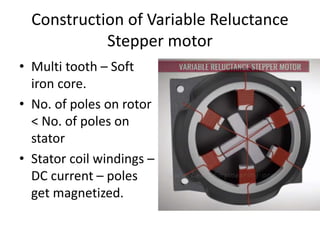

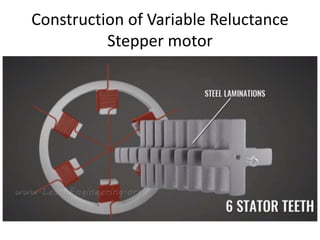

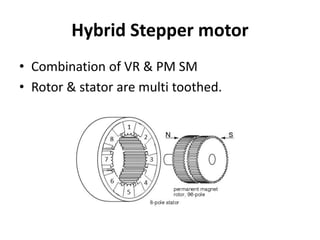

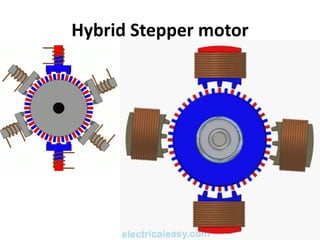

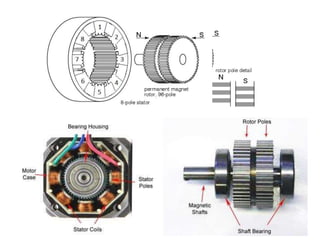

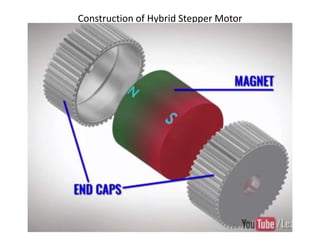

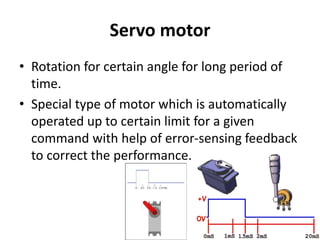

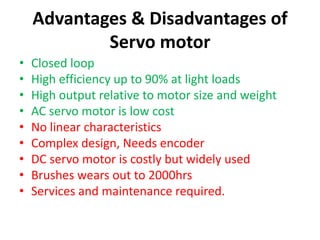

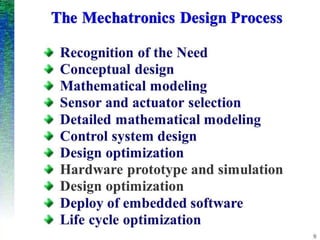

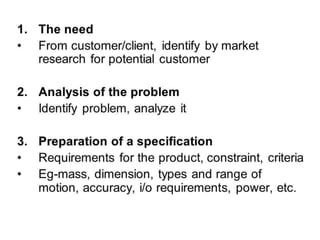

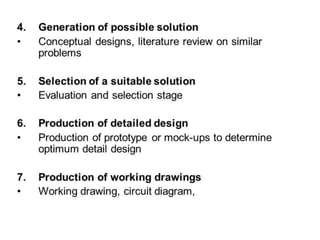

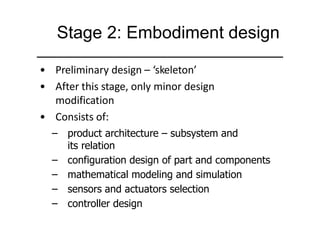

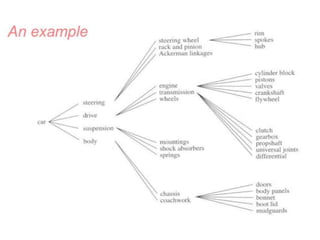

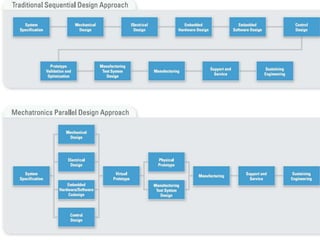

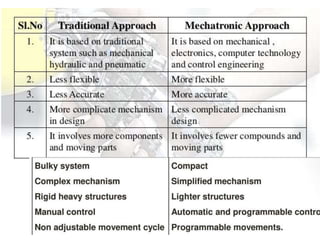

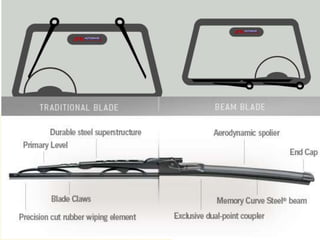

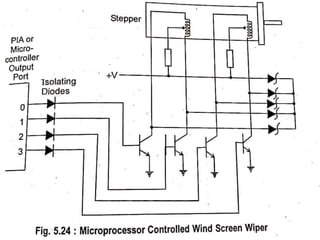

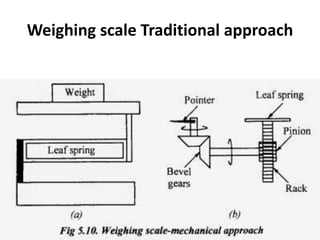

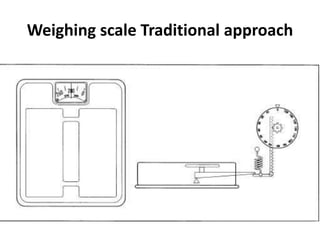

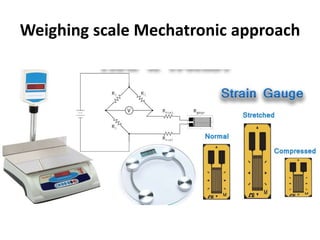

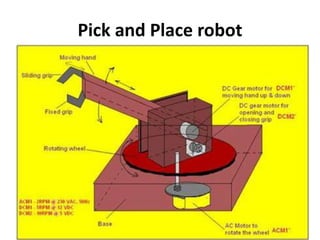

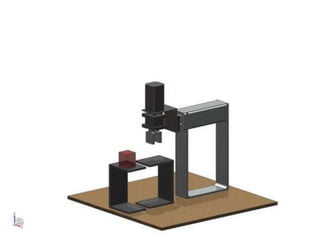

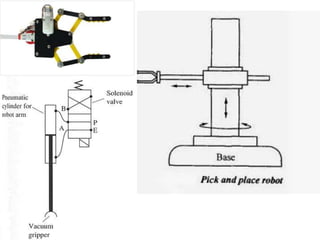

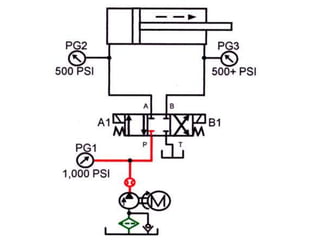

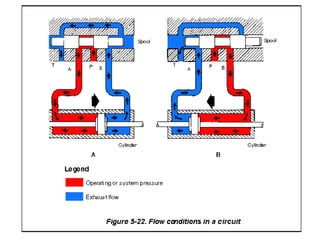

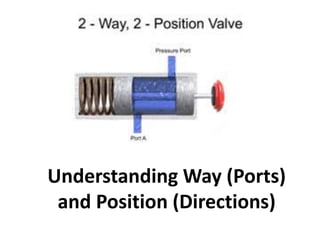

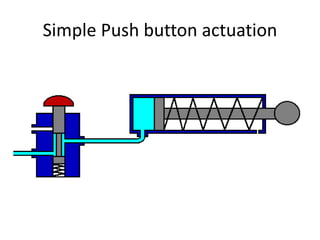

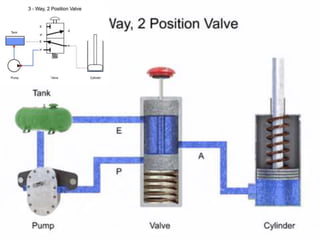

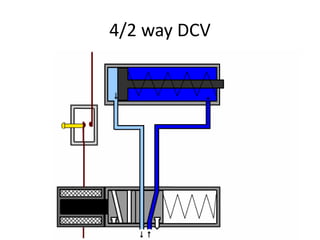

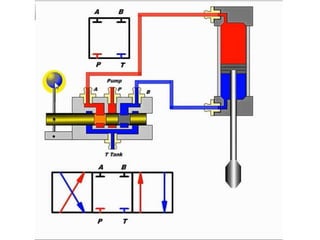

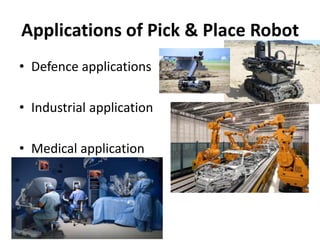

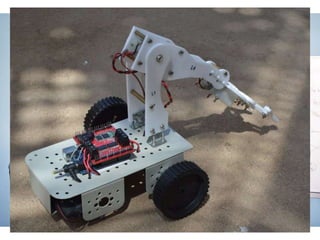

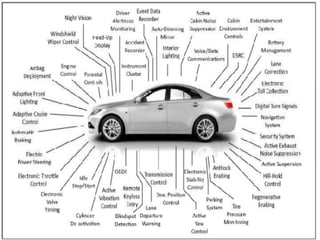

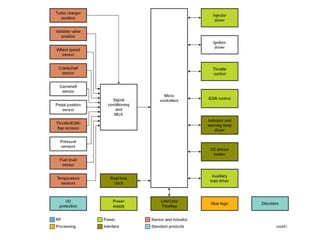

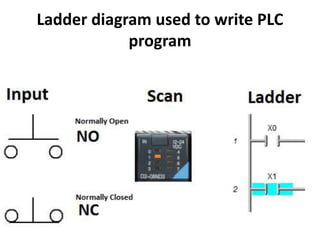

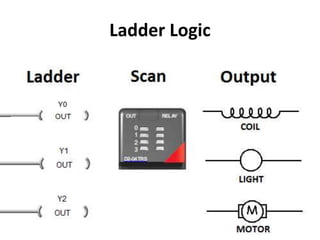

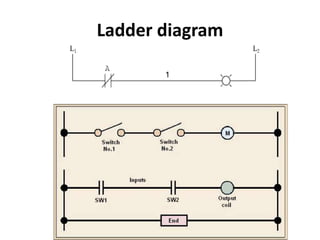

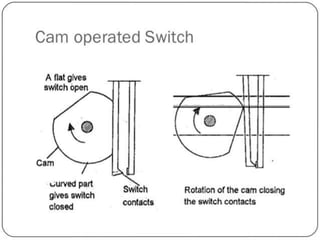

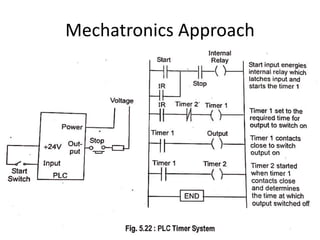

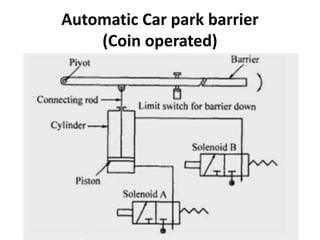

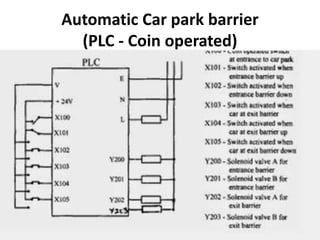

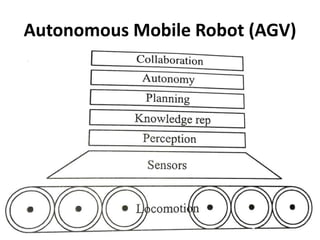

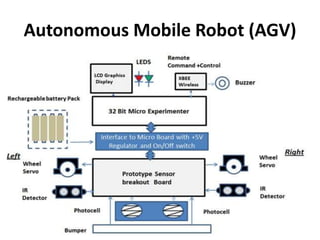

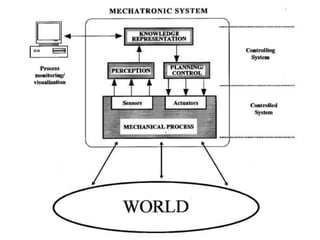

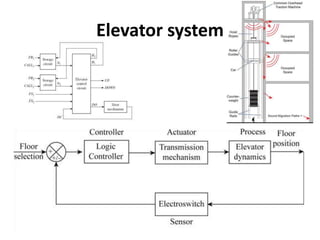

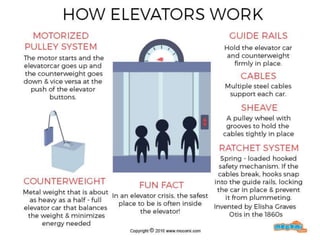

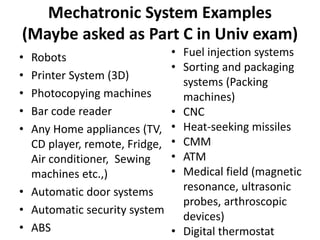

This document provides an overview of actuators and mechatronic system design. It defines actuation as the conversion of any form of energy into mechanical form. The device that performs this conversion is called an actuator. Various types of actuators are classified, including electrical, mechanical, hydraulic/pneumatic, and active material-based actuators. Common actuators like motors, solenoids, and piezoelectric materials are described. The document also discusses concepts like mechatronic design approaches, case studies of various mechatronic systems, and the differences between traditional and mechatronic design methods.