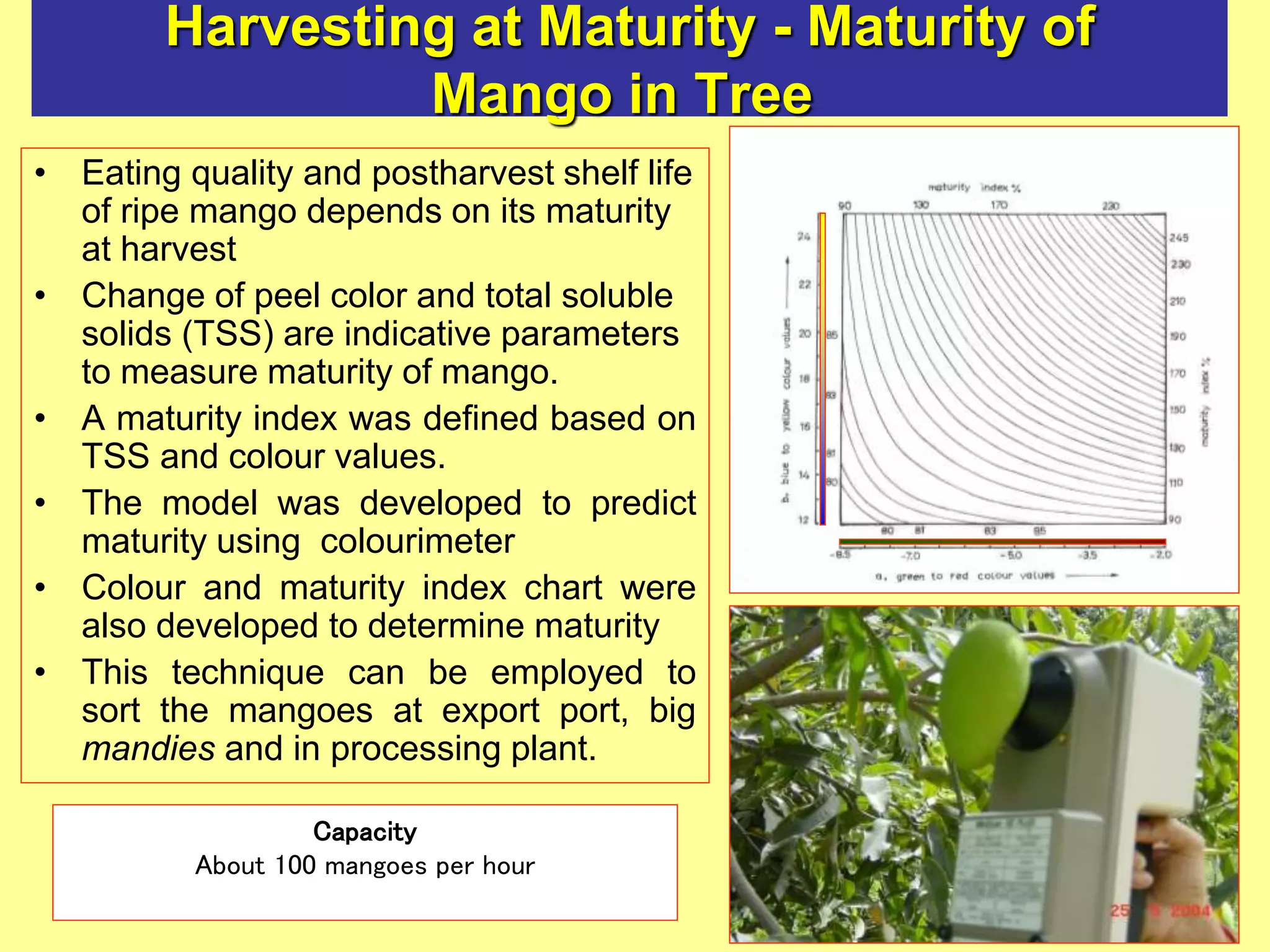

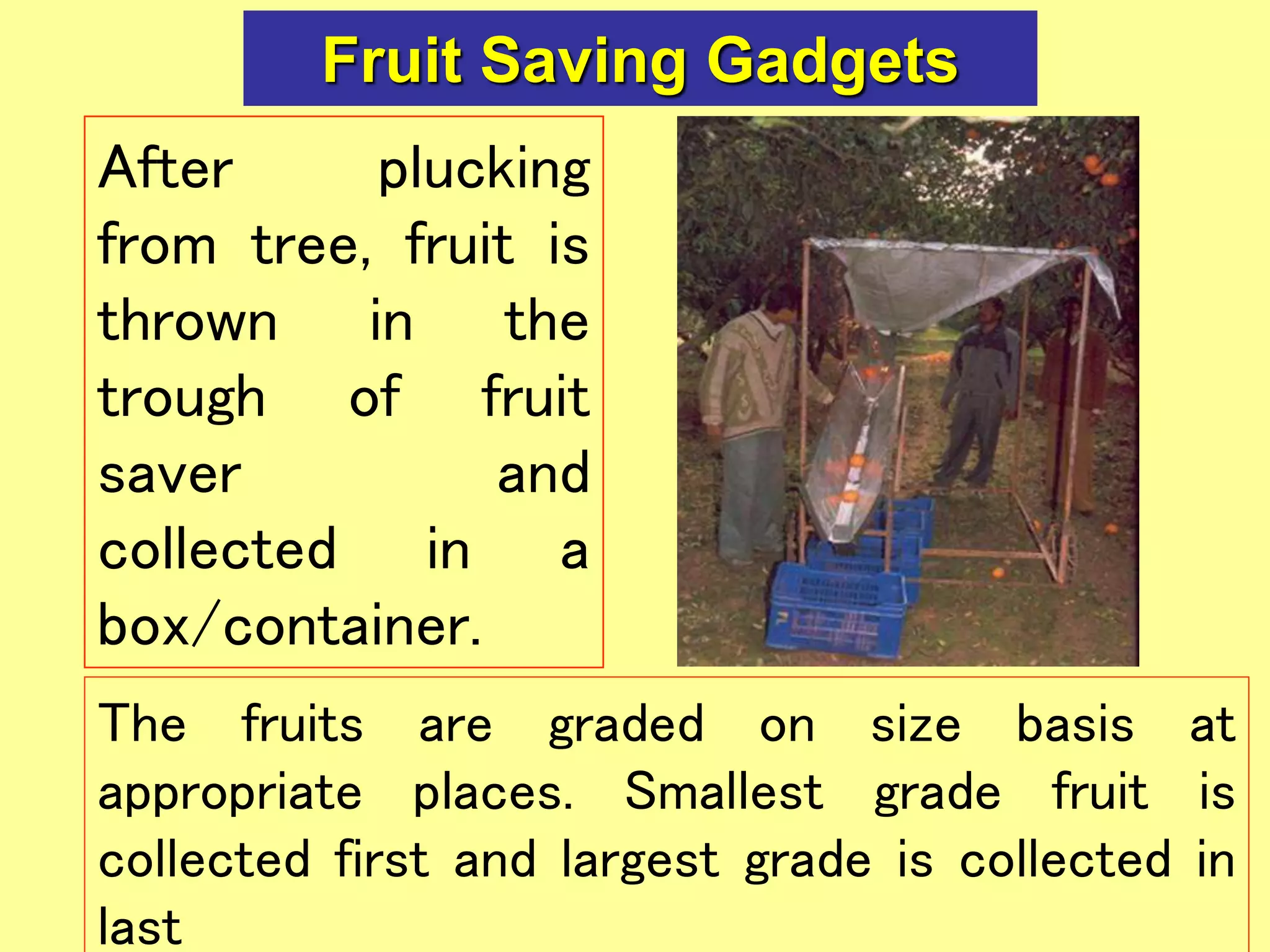

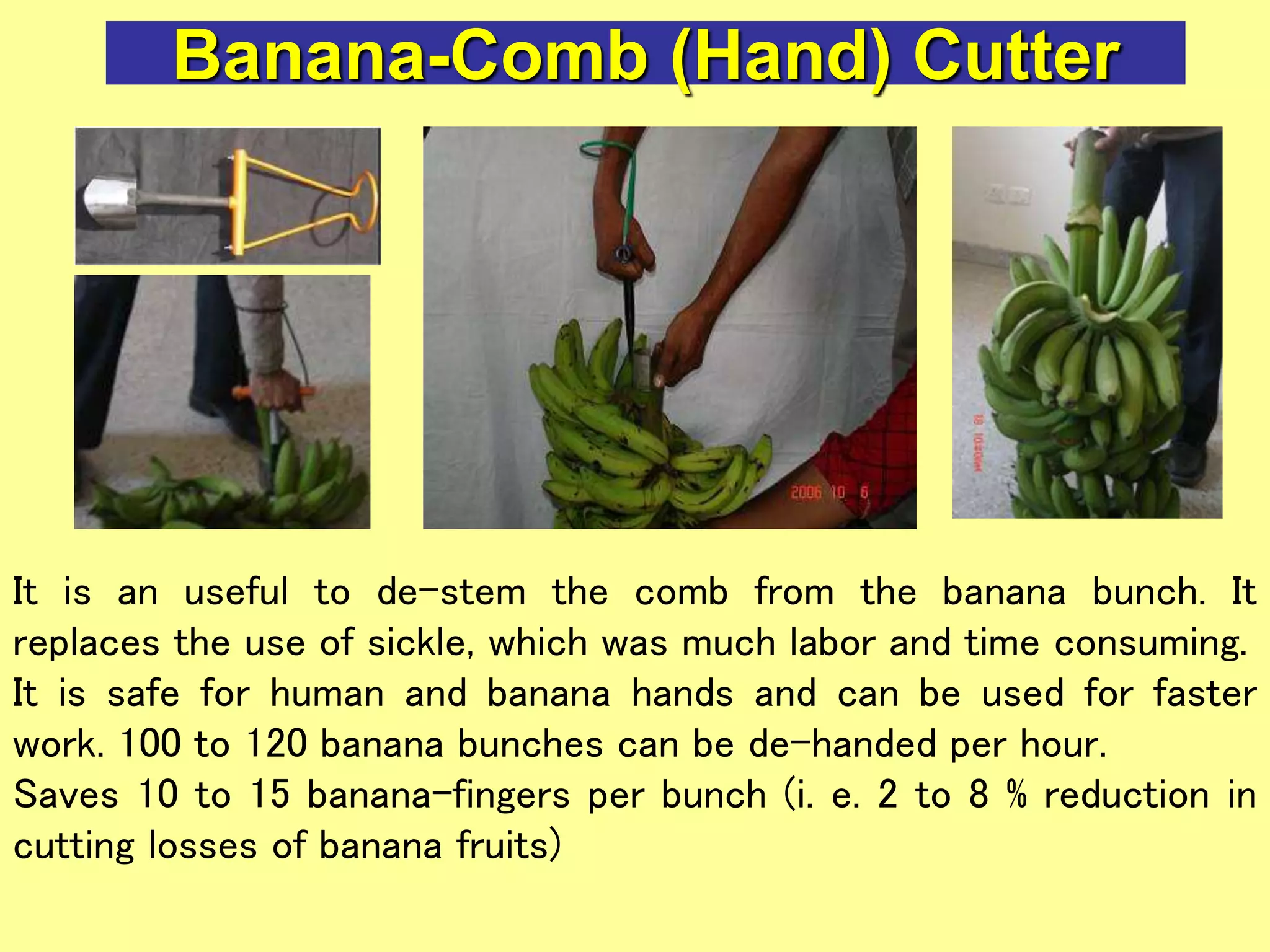

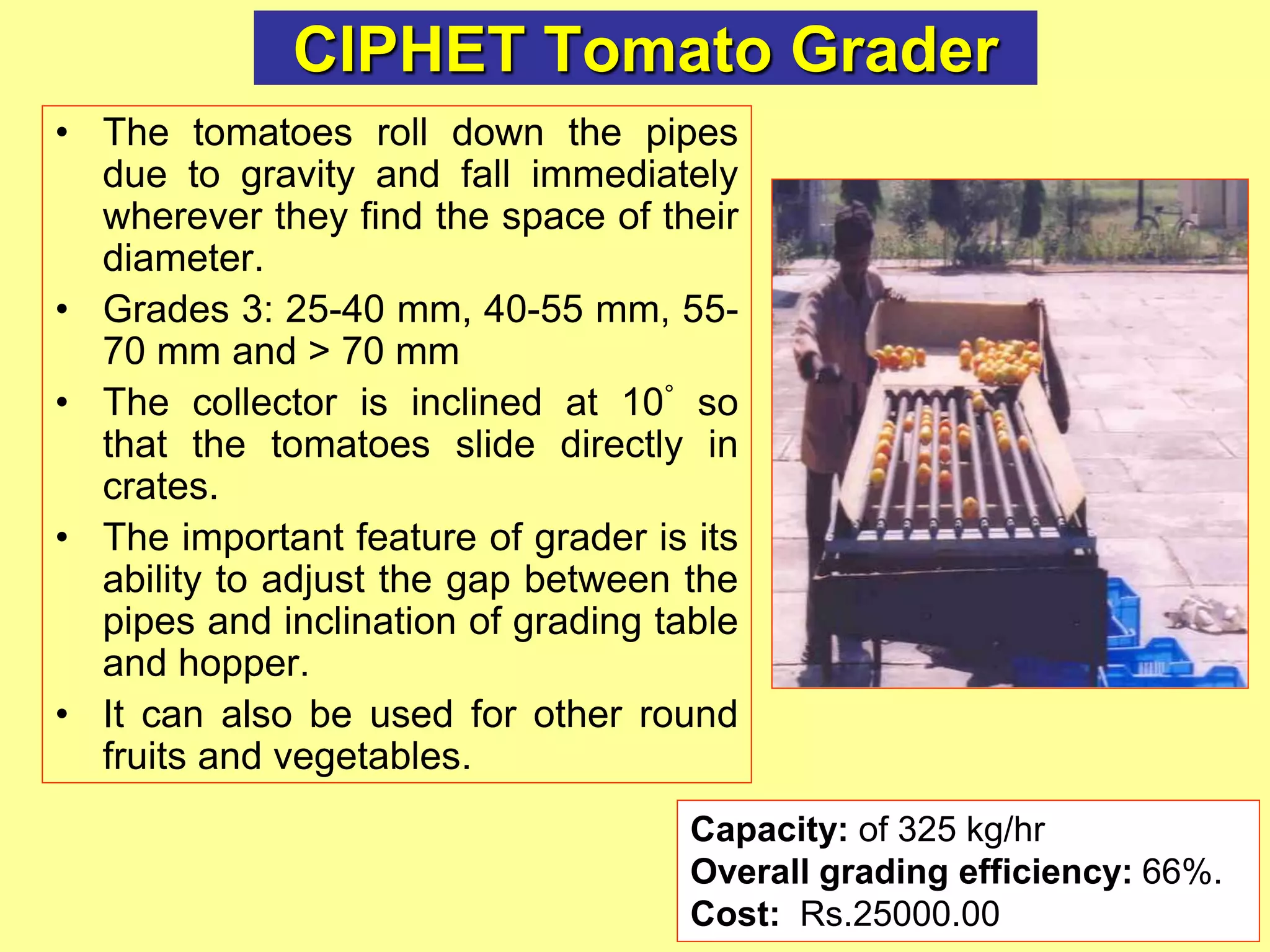

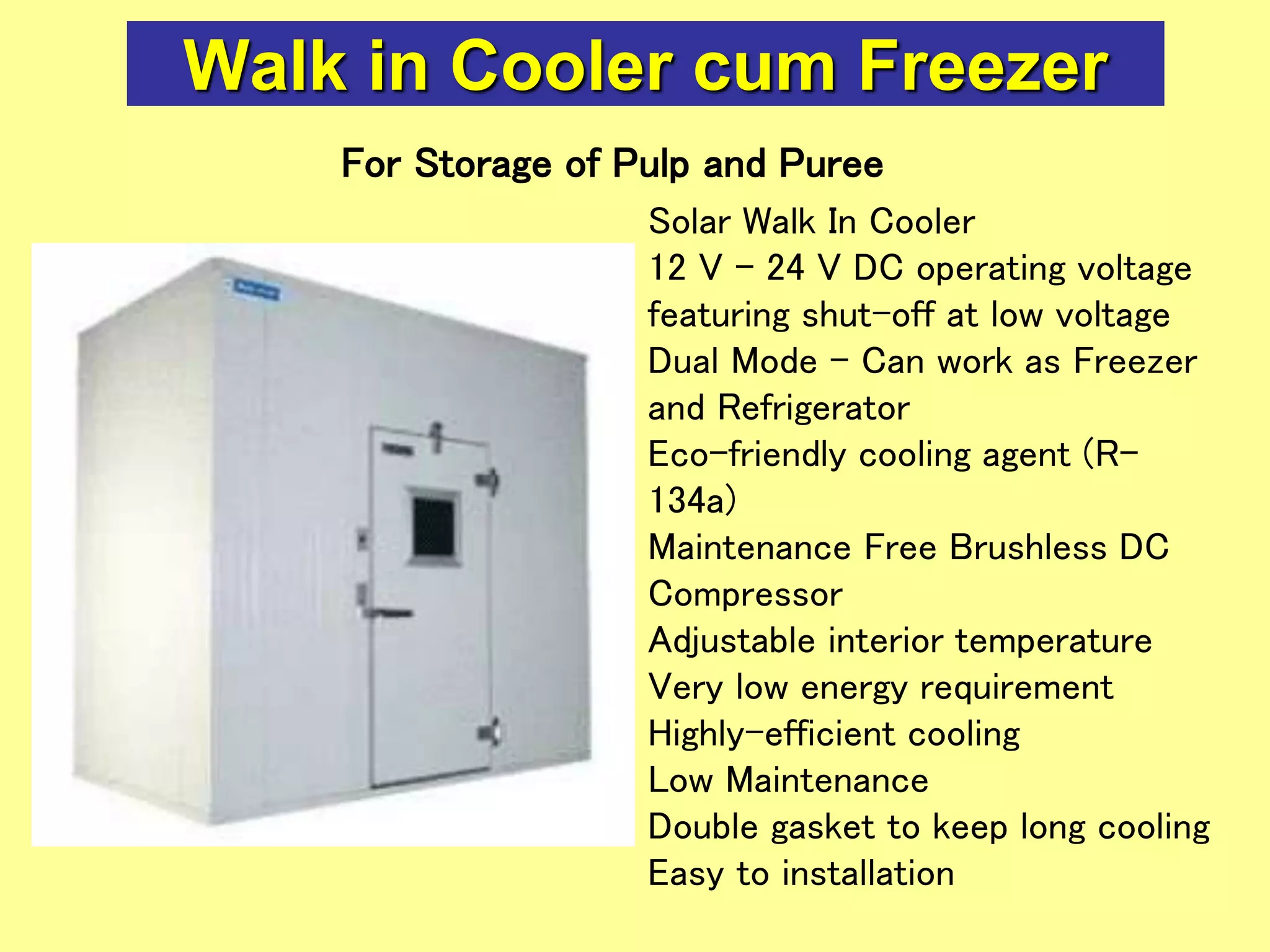

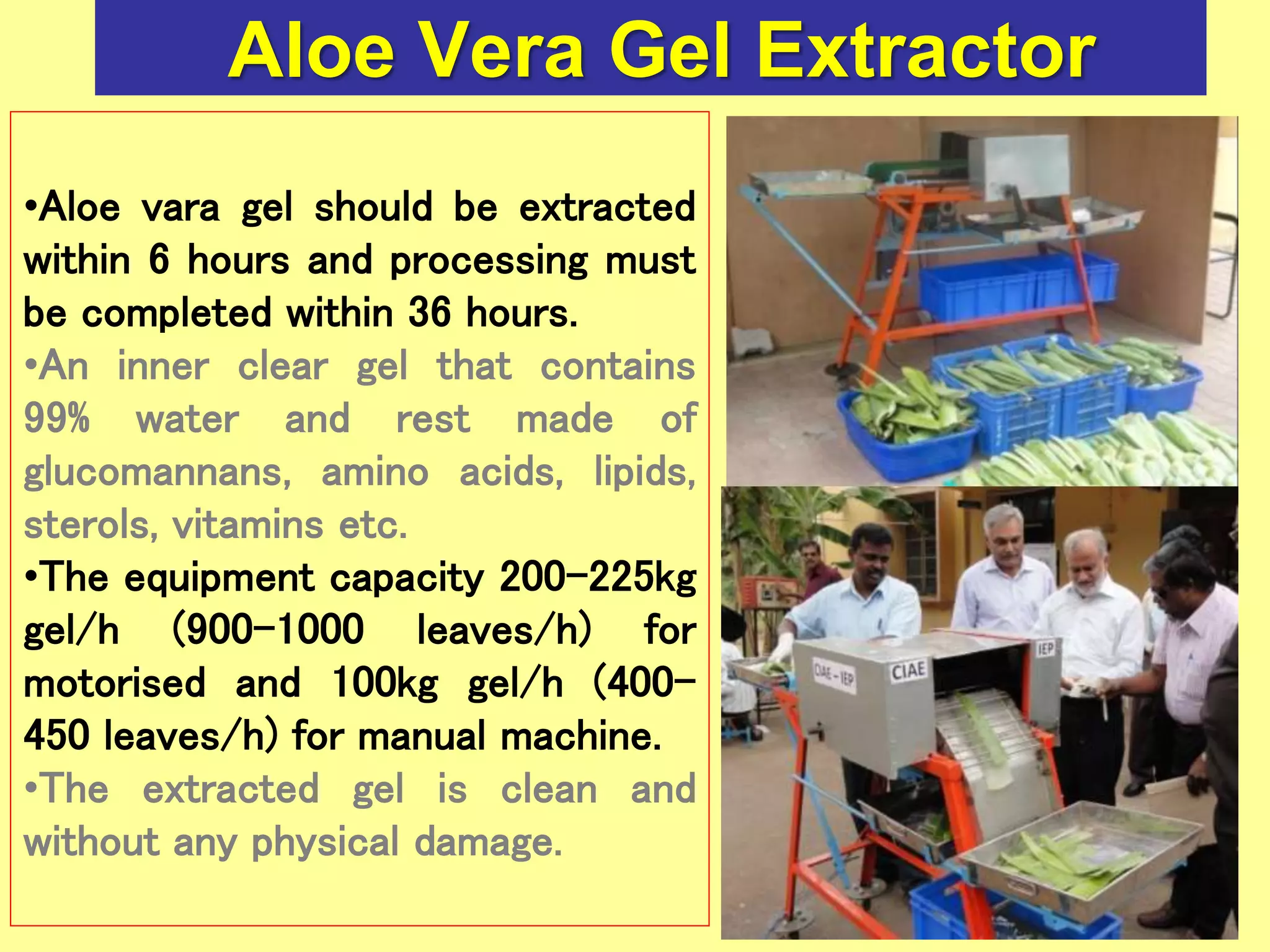

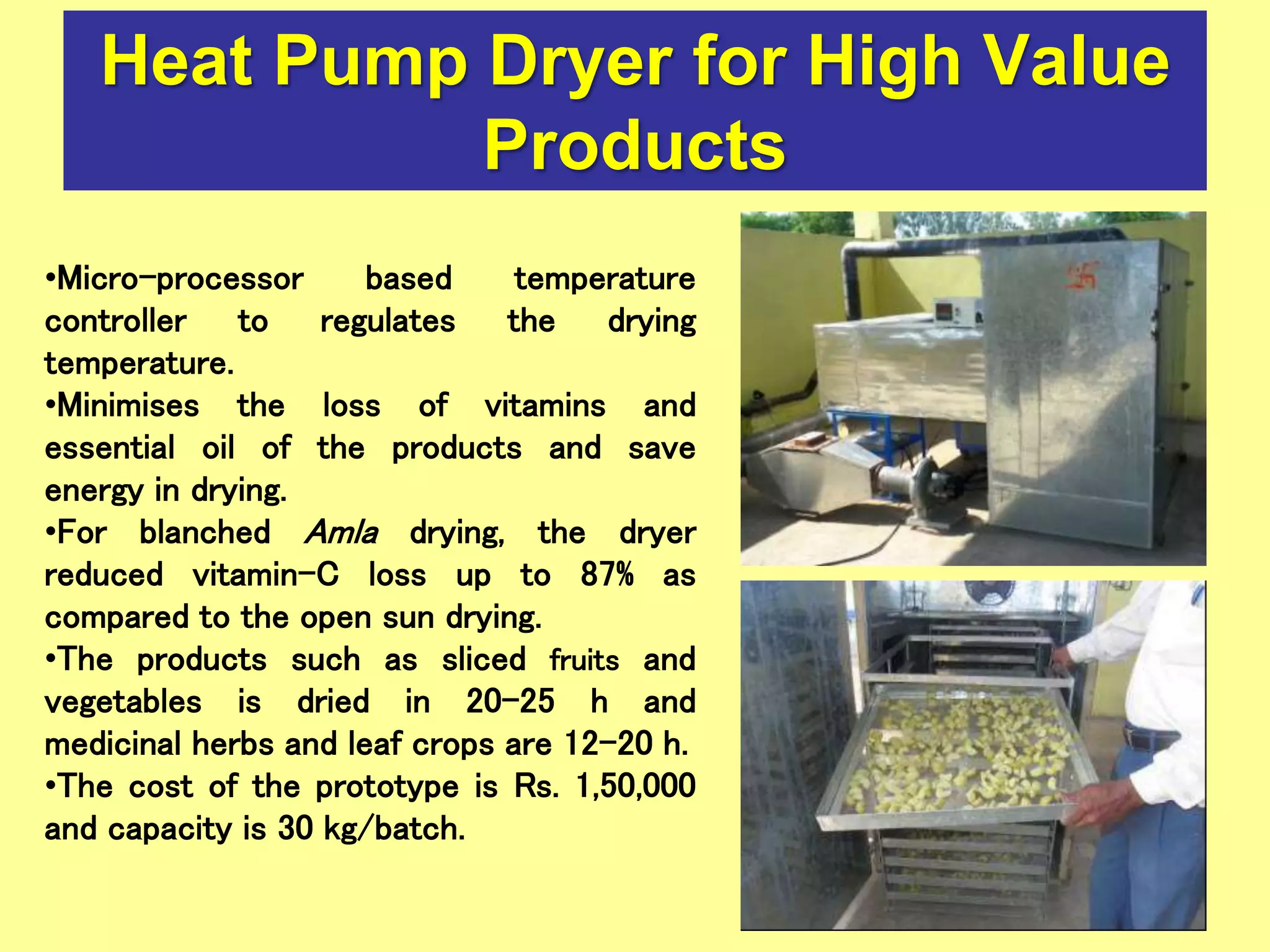

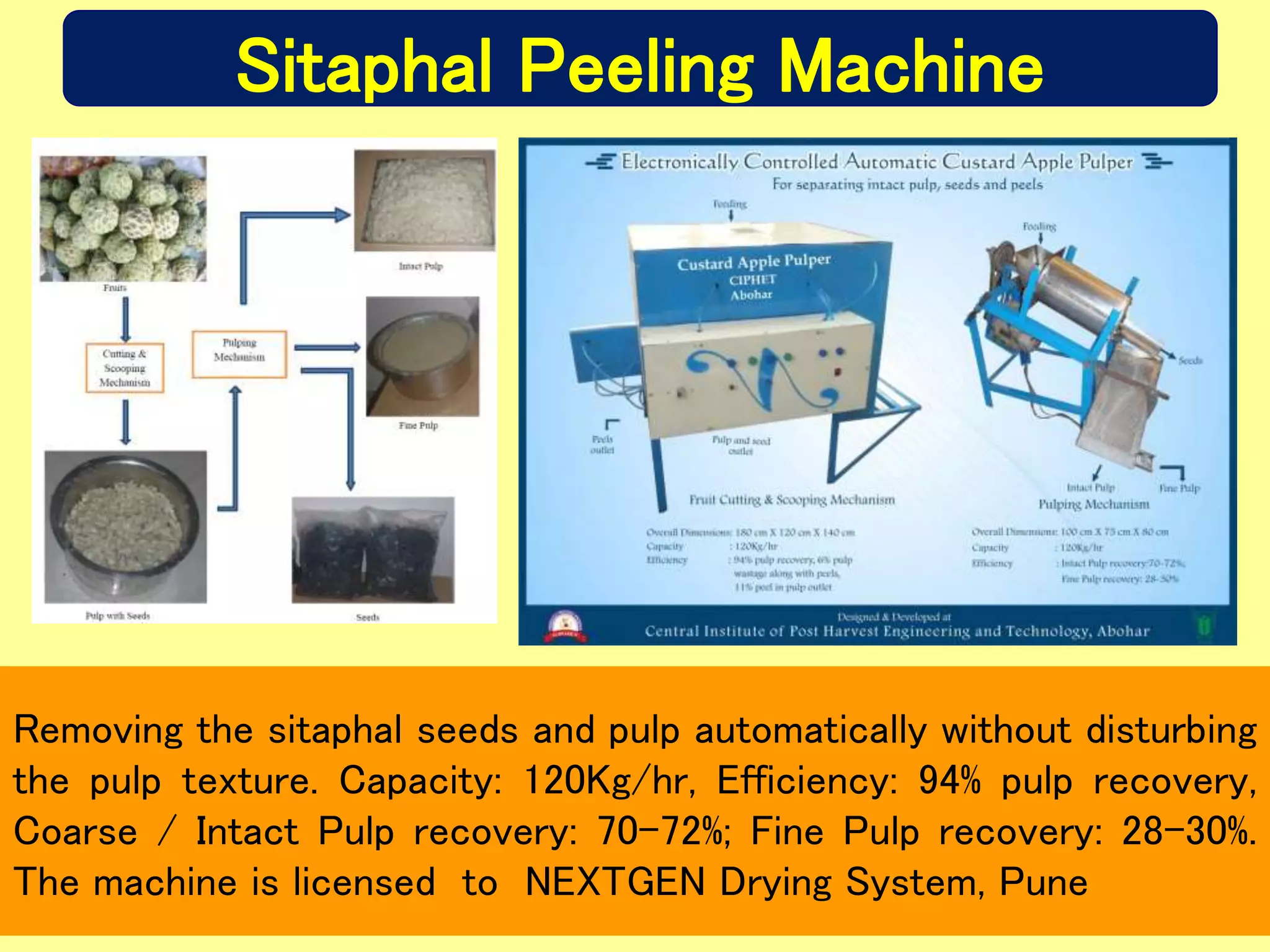

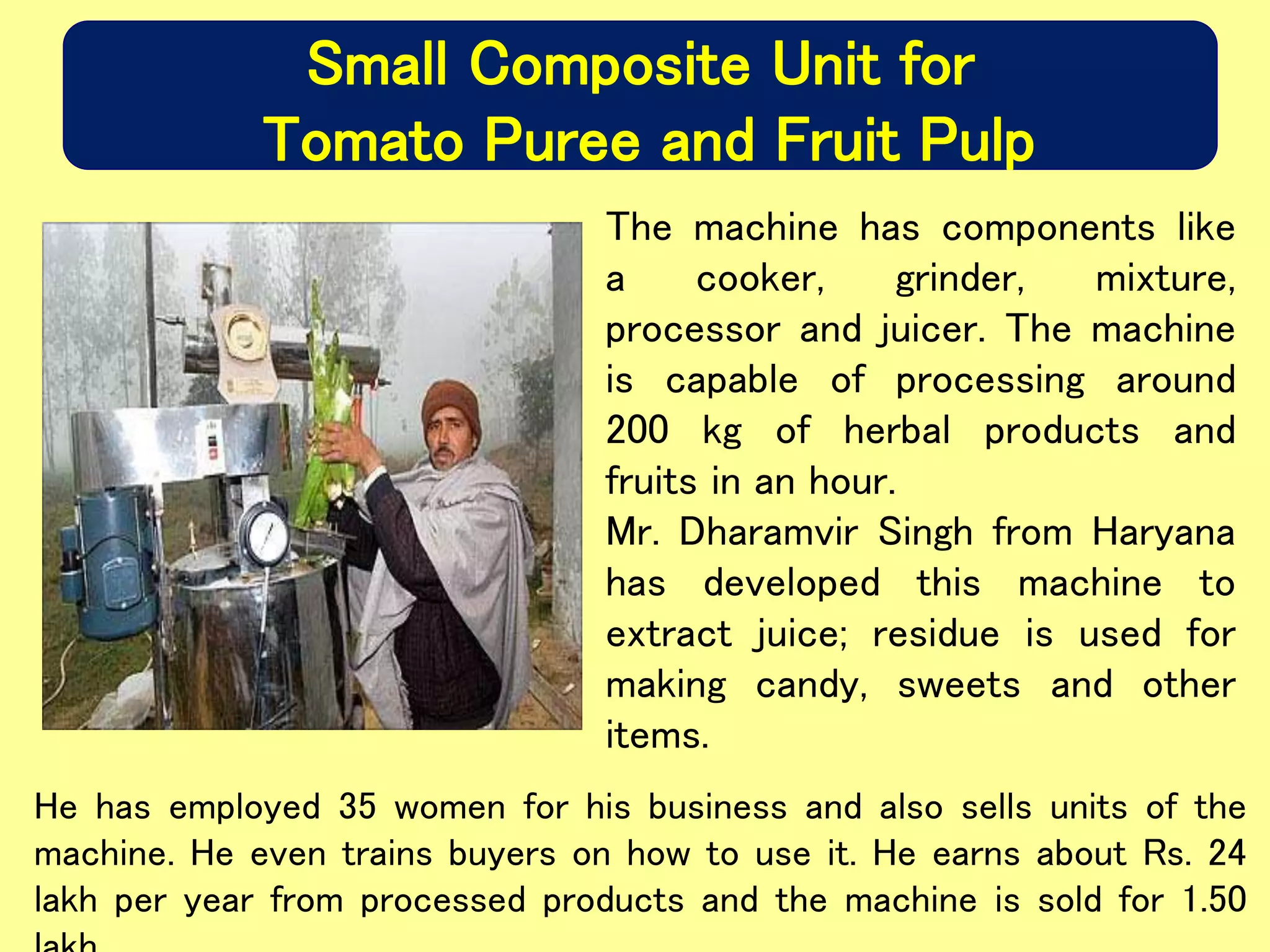

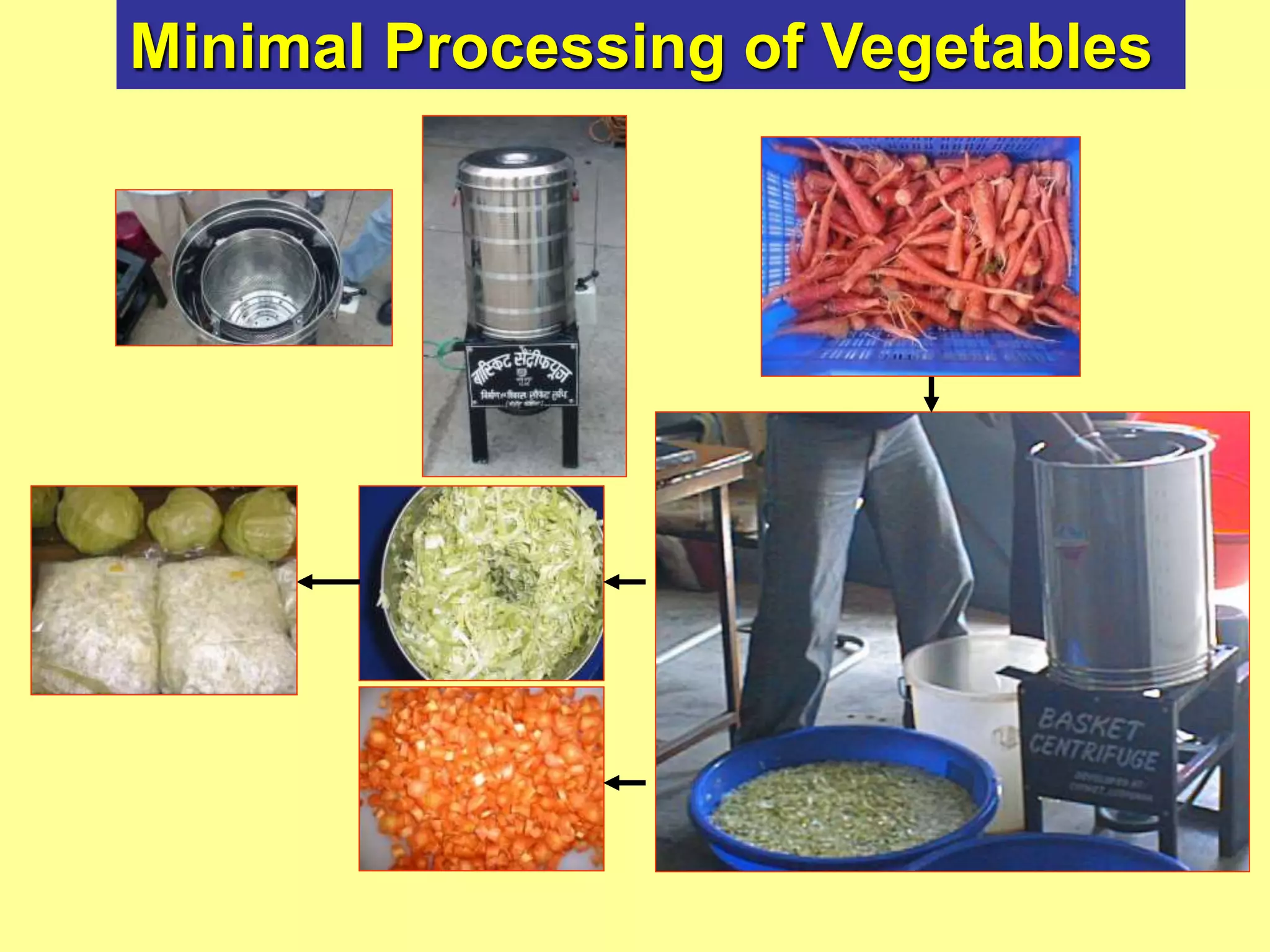

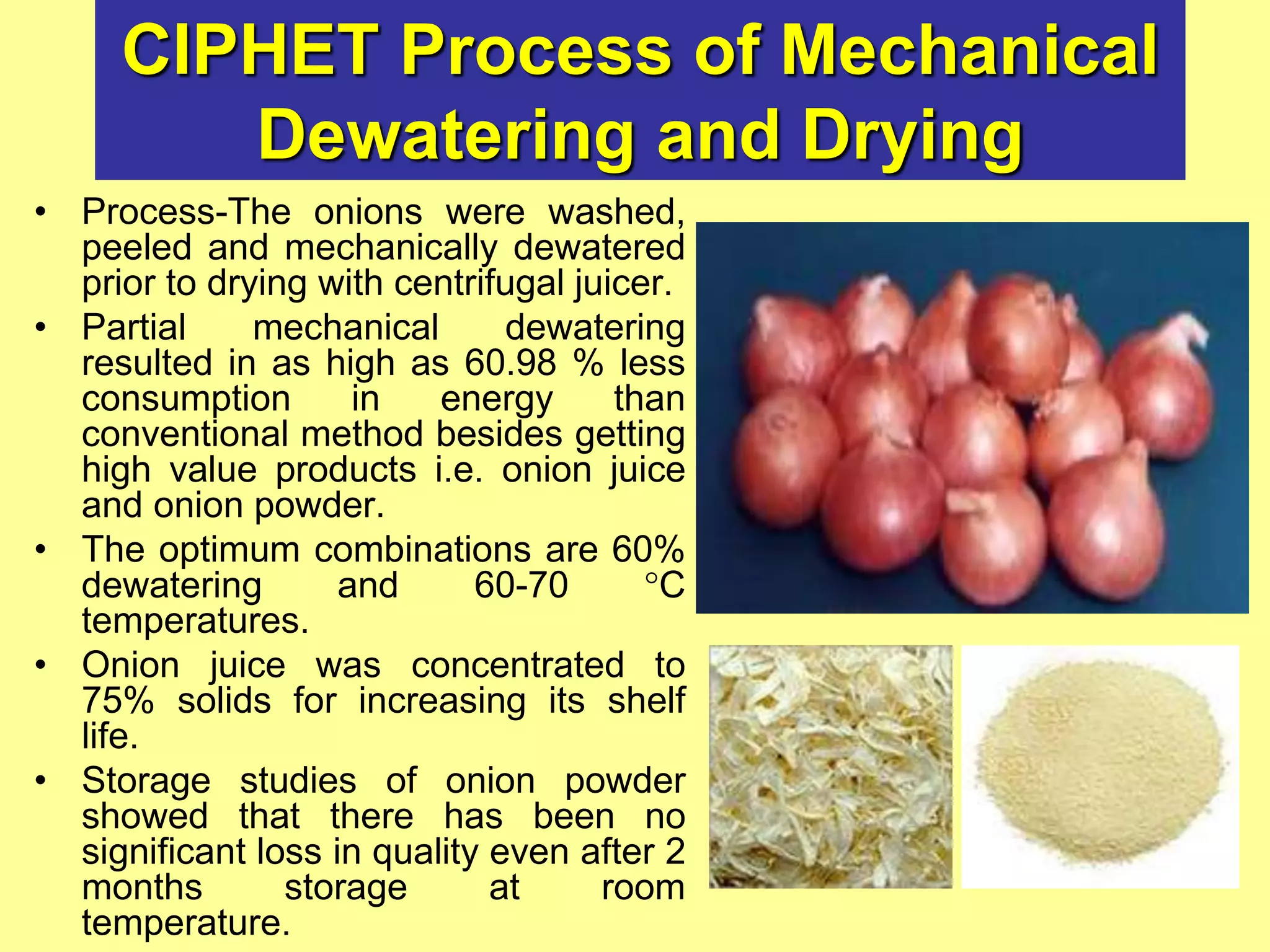

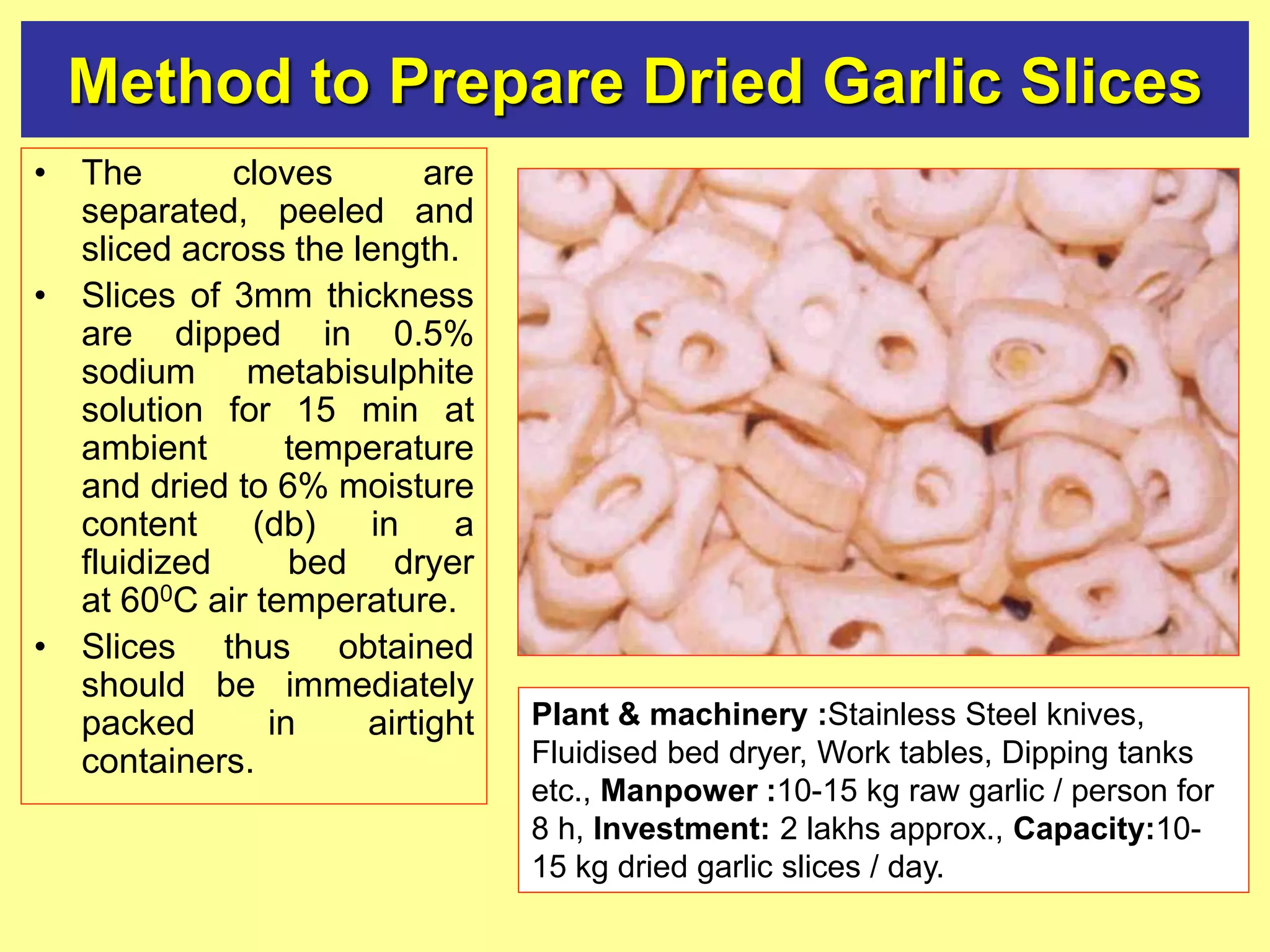

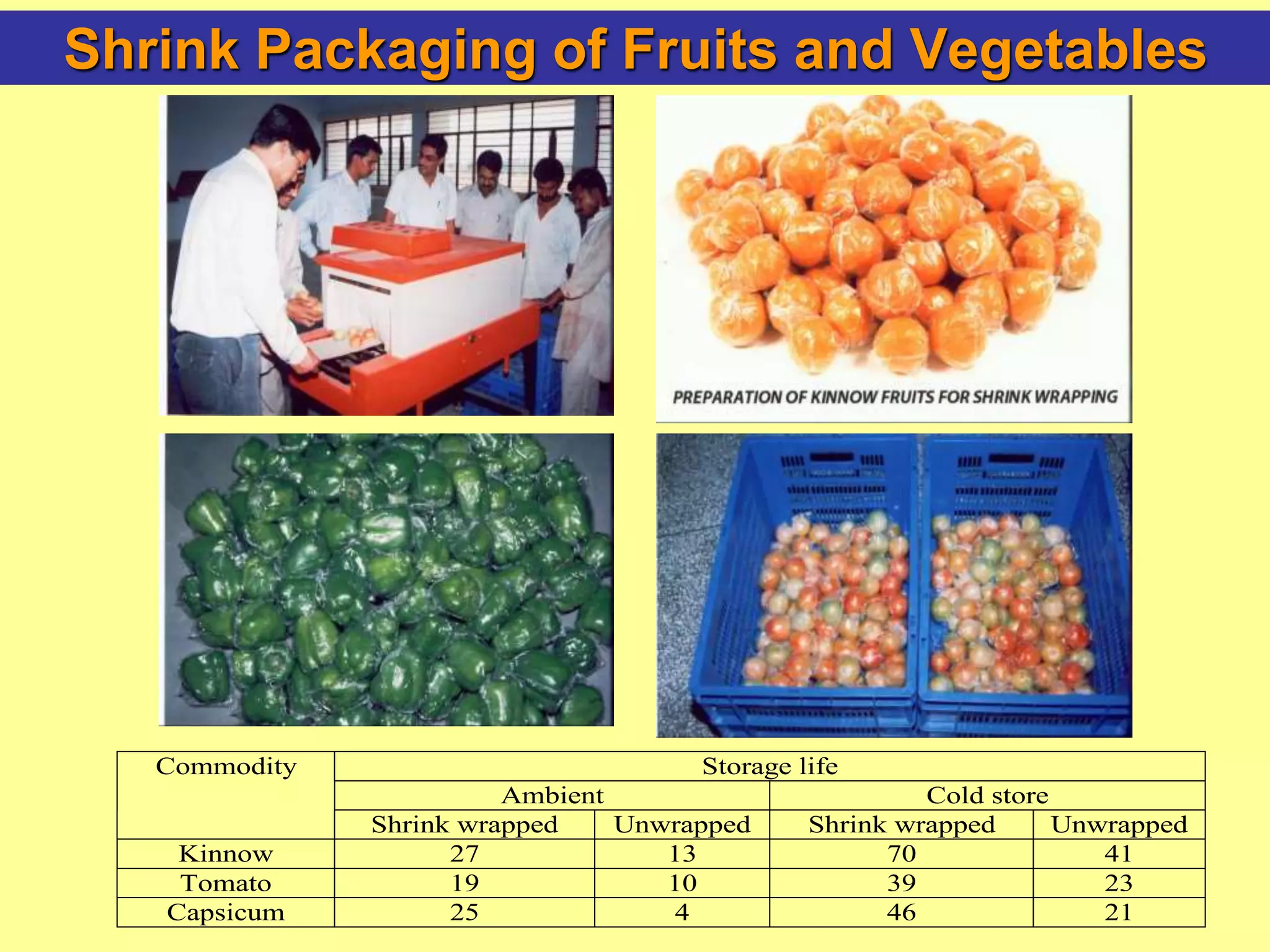

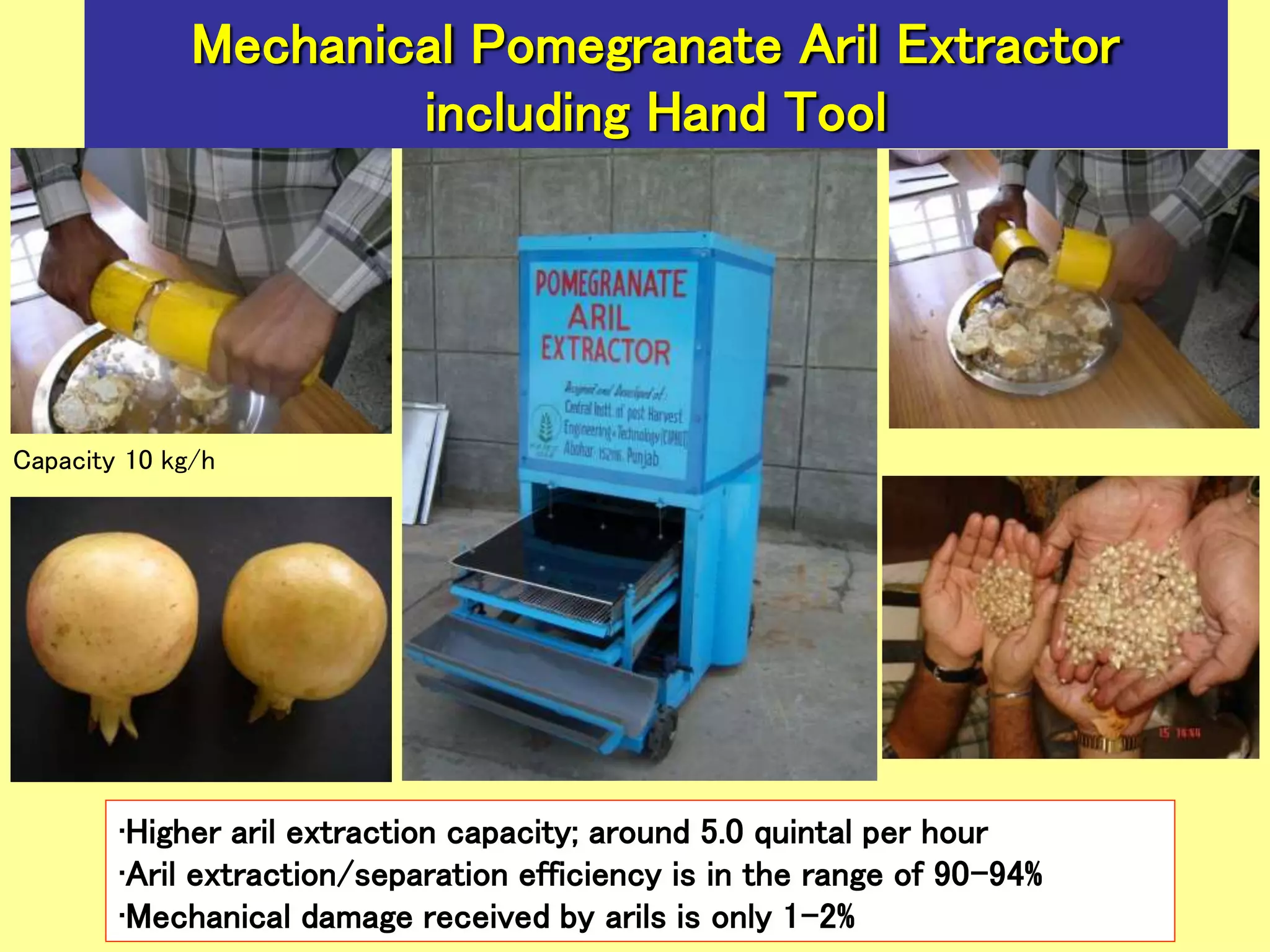

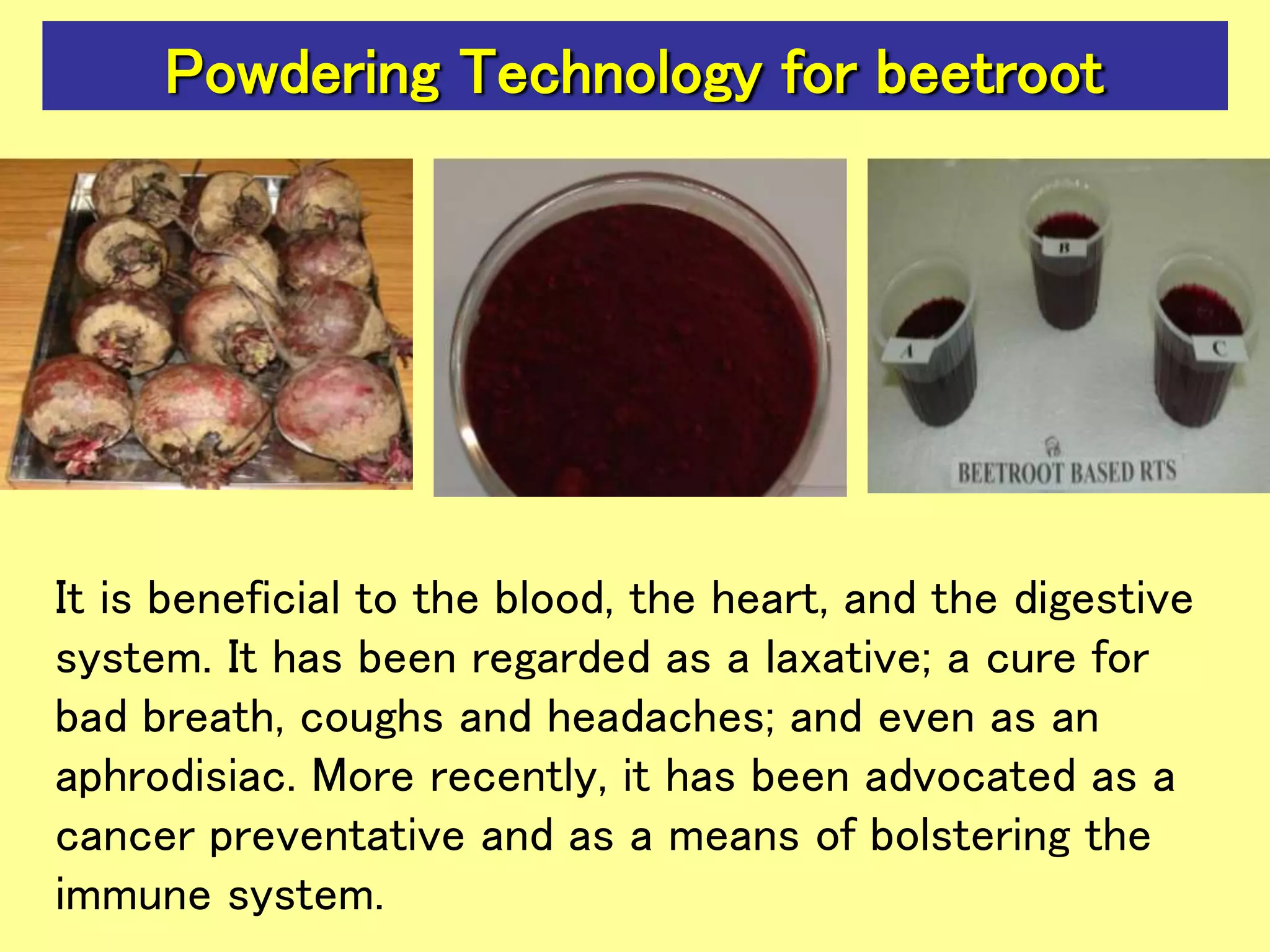

This document discusses various technologies related to post-harvest operations in horticultural crops. It begins by providing context on agriculture and horticulture production and post-harvest losses in India. It then describes the benefits of agro-processing in production areas and lists the main unit operations in post-harvest management. The document proceeds to describe several specific post-harvest technologies and machinery, including bunch covers for bananas, tools for safe harvesting, grading and sorting equipment, pre-cooling, storage structures, and machinery for processing fruits and vegetables into products like juices, pulps, and dried or value-added items. It concludes by discussing some packaging technologies that can extend the shelf life of horticultural crops.