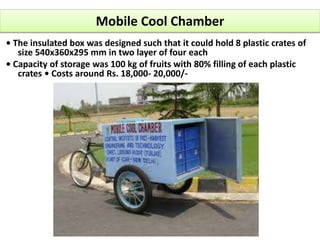

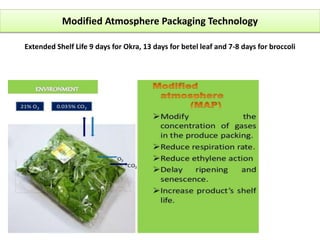

Post harvesting management includes processes done immediately after harvesting produce like cooling, cleaning, sorting and packing. It is important as crops begin deteriorating after harvesting. Post harvesting largely determines final quality and minimizes 40% losses in fruits and vegetables due to improper handling, storage, packaging and transportation. Losses occur due to lack of infrastructure, technical support and organized marketing. Deterioration is caused by microorganisms, enzymes, insects and environmental factors like temperature and moisture. Proper post harvesting practices like pre-cooling, modified atmosphere packaging and storage in zero energy cool chambers can extend shelf life.