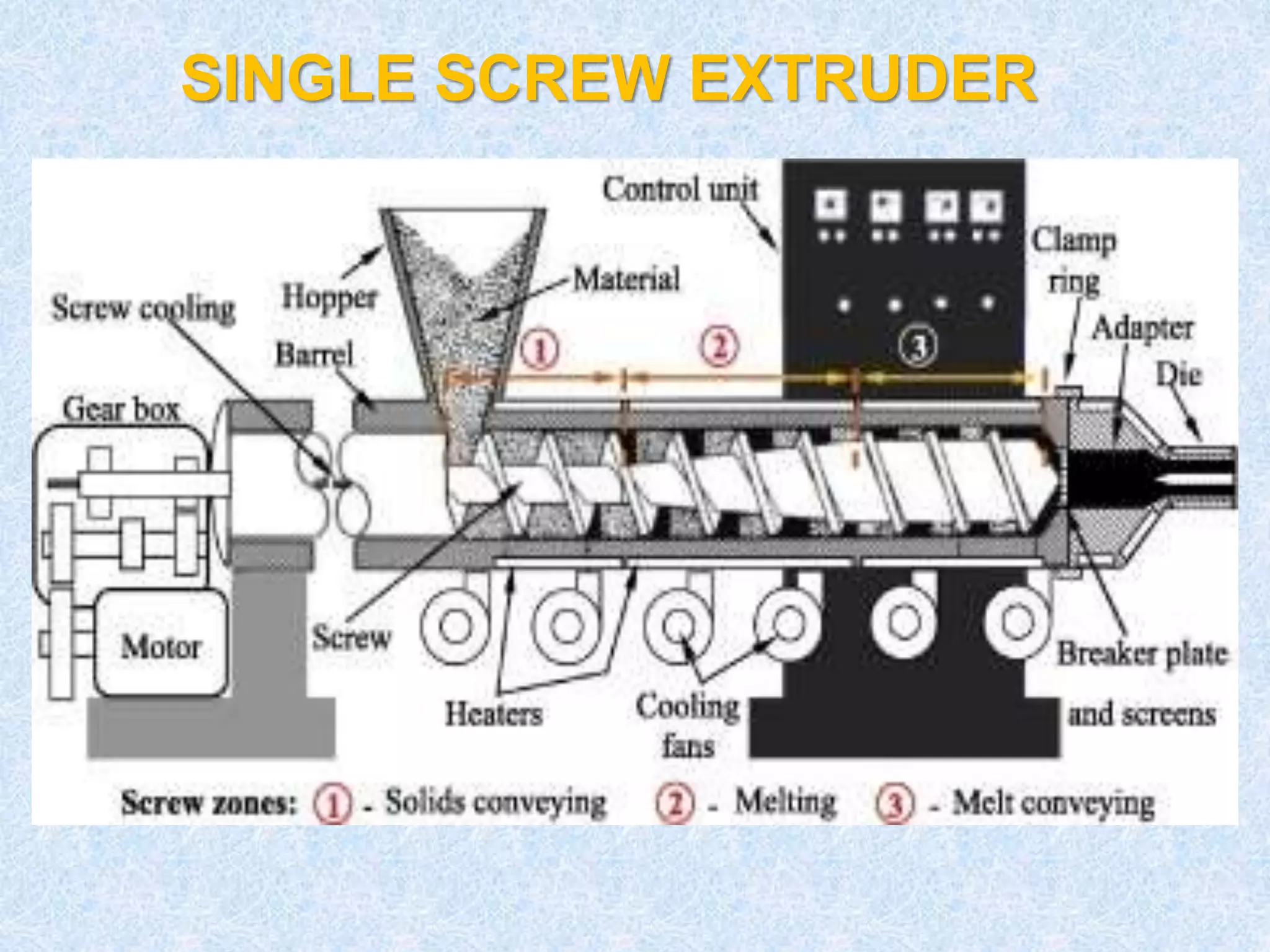

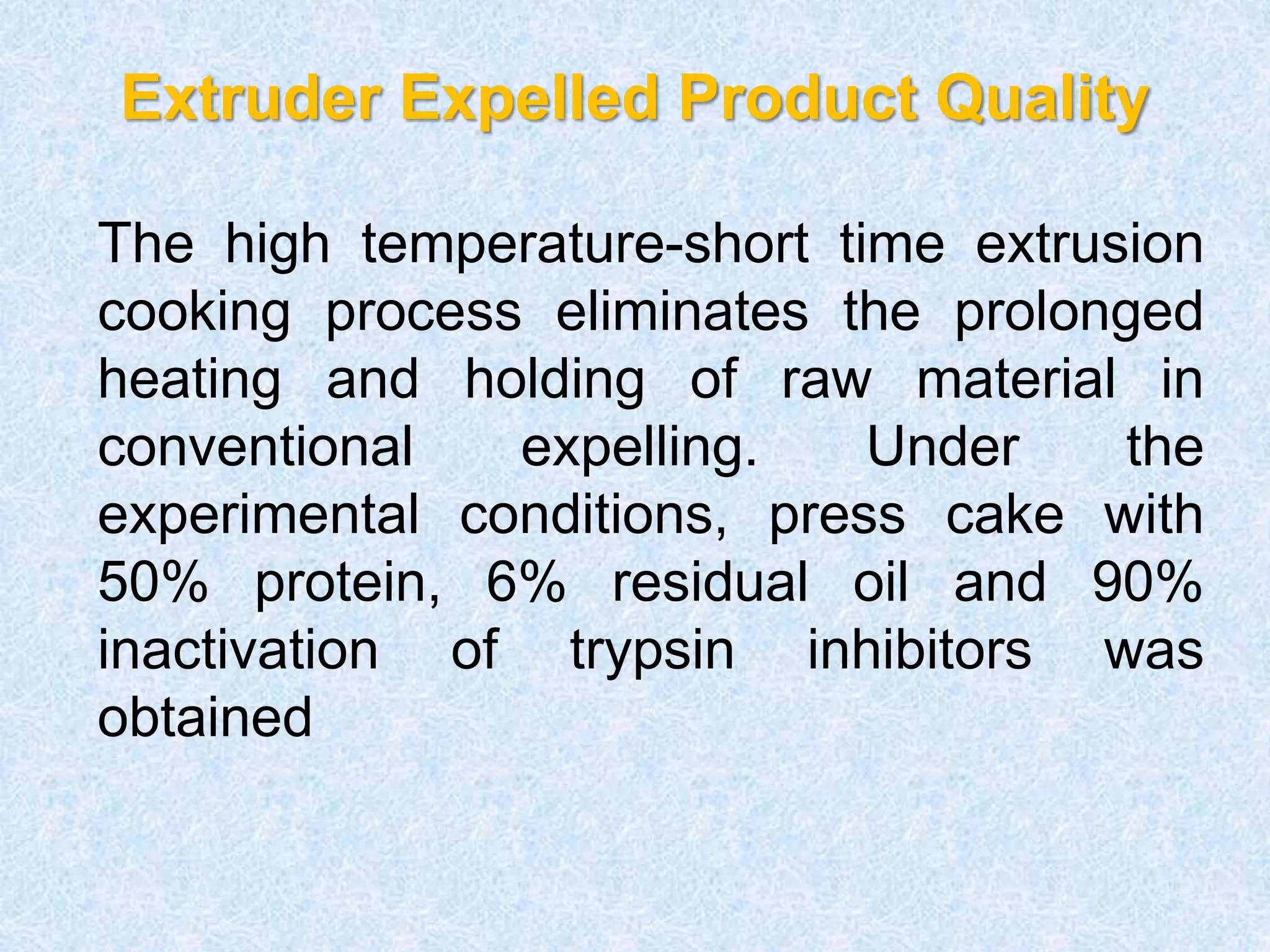

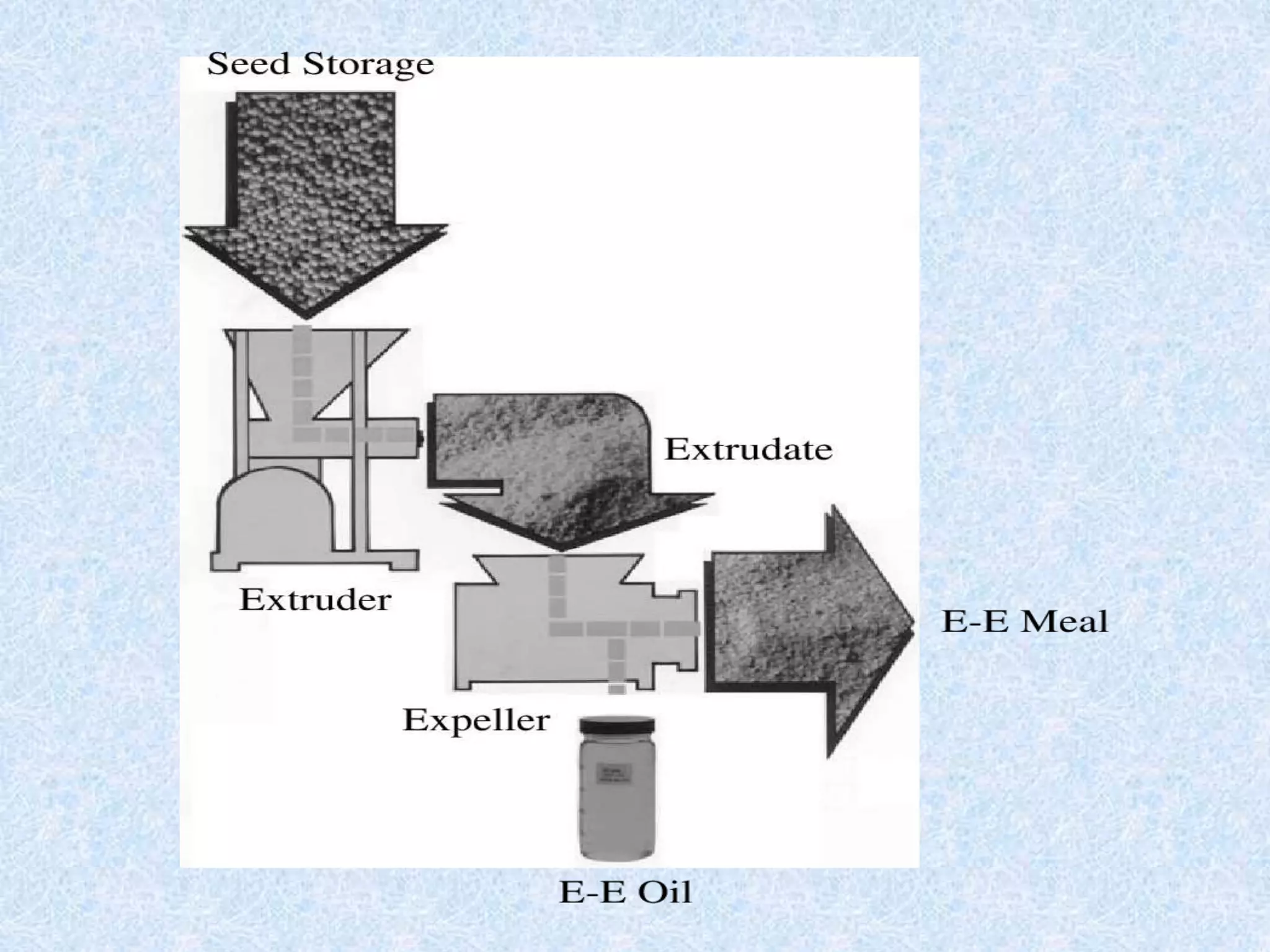

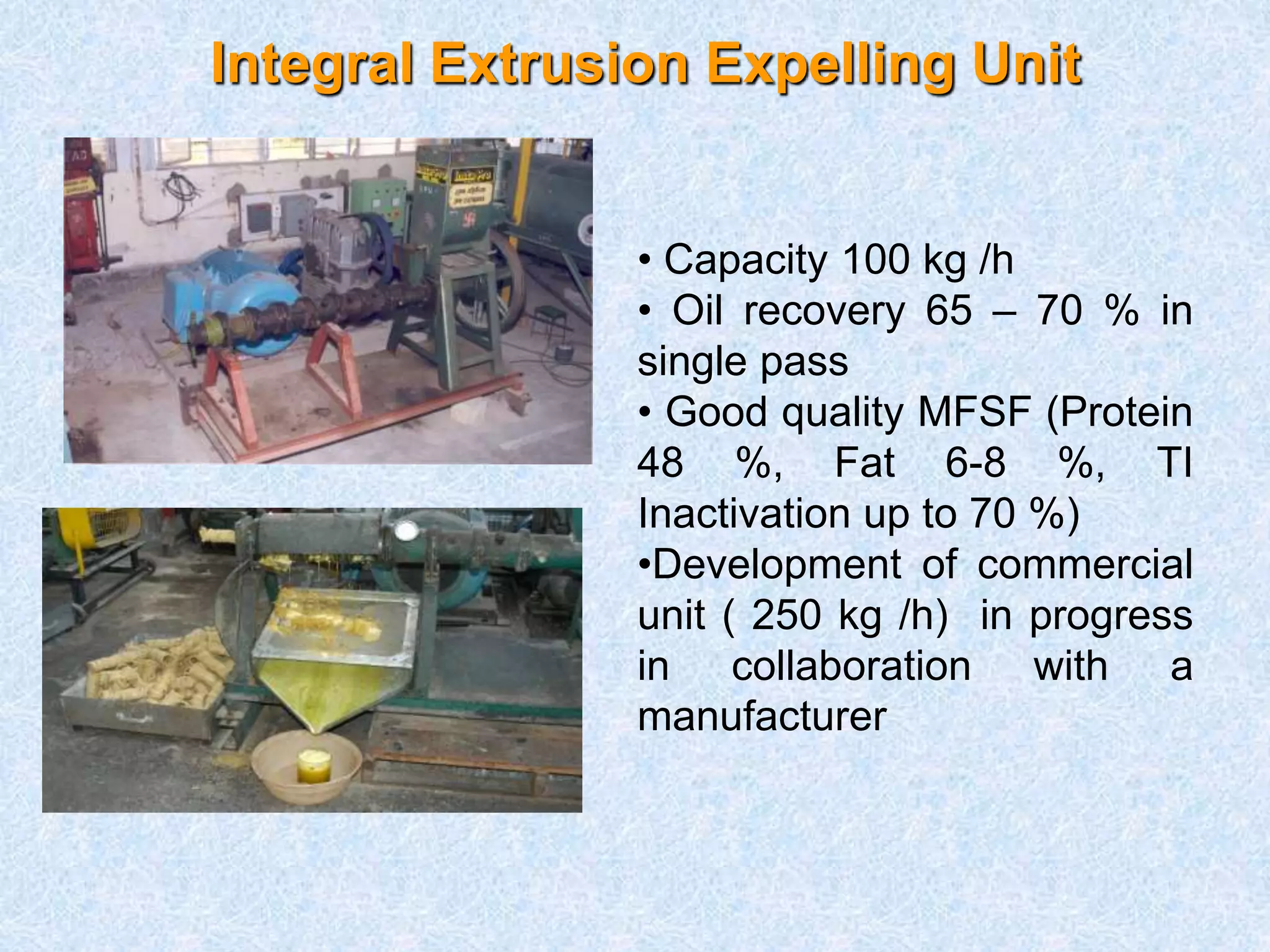

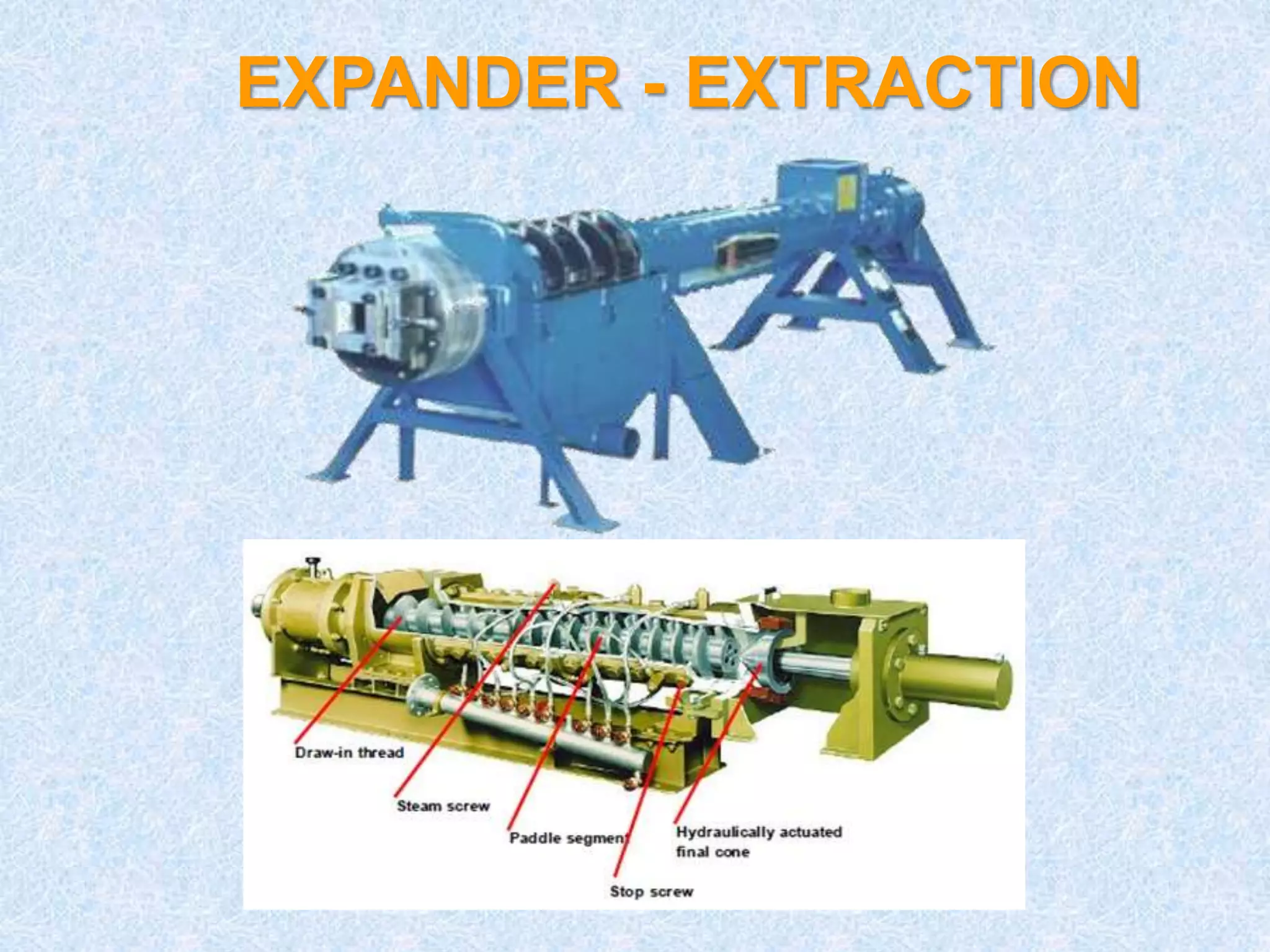

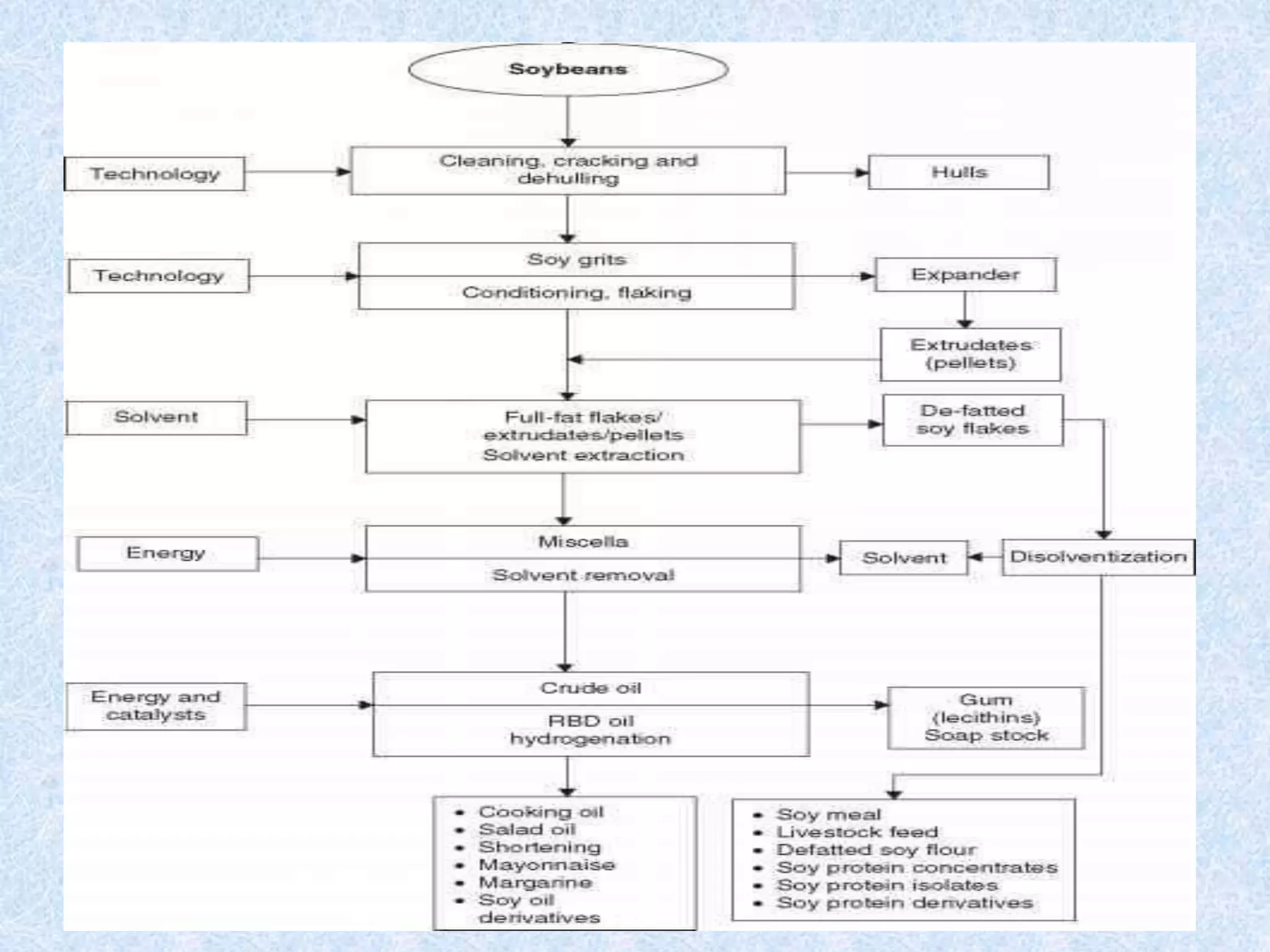

This document discusses different techniques for oil extraction from oilseeds, including expellers and extruders. It notes that India produces 33 million tonnes of oilseeds annually but loses around 6% to inefficient processing. Traditional animal-powered expellers recover only 15% oil from the seed cake, while modern mechanical expellers and solvent extraction plants recover 6-8% and less than 1% respectively. The document then examines single screw extruders and expanders for oil extraction. It finds that extruders using short heating times can extract 50-75% of oil in one pass while maintaining high protein levels and inactivating trypsin inhibitors in the seed cake. Integral extrusion expelling units that combine extrusion and pressing show