The document discusses different types of extruders and expellers used in food processing. It provides information on:

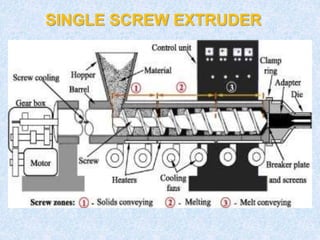

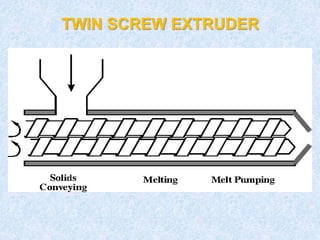

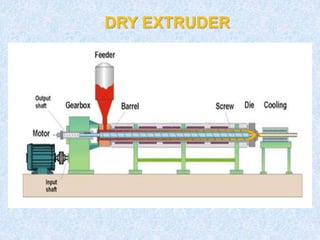

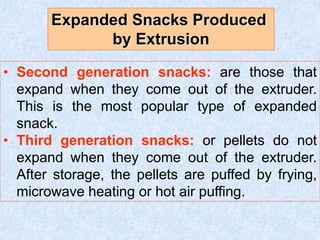

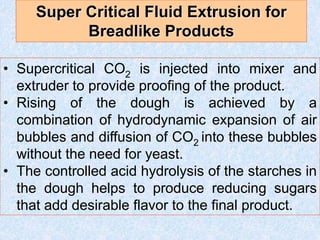

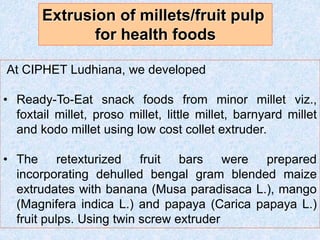

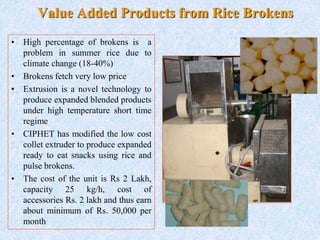

1) Extruders that use shear and pressure to mix, cook, and form foods in a continuous process. They are used to make breakfast cereals, snacks, pet foods and more.

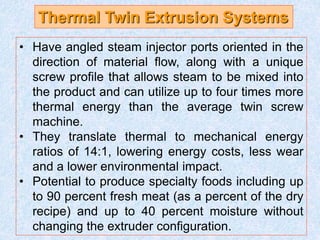

2) Classification of extruders including single-screw, twin-screw, and types based on shear stress levels.

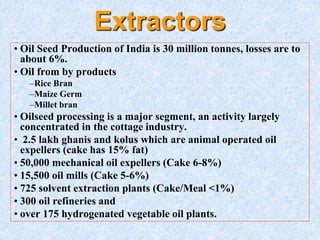

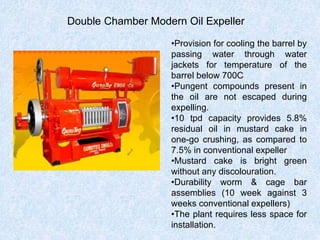

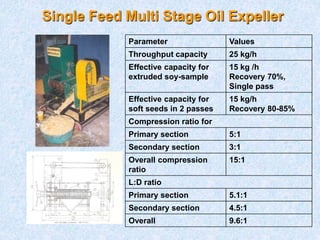

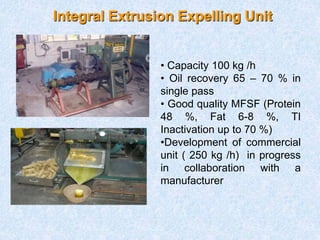

3) Expellers that use compression to mechanically extract oil from seeds with higher efficiency than traditional methods. Modern expellers have improved recovery rates and product quality.

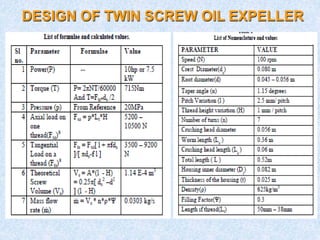

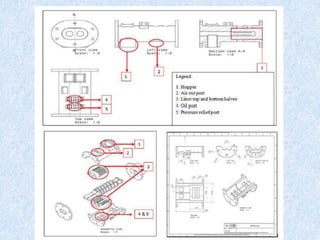

4) Research developing expeller technologies like a twin-screw expeller and an integral