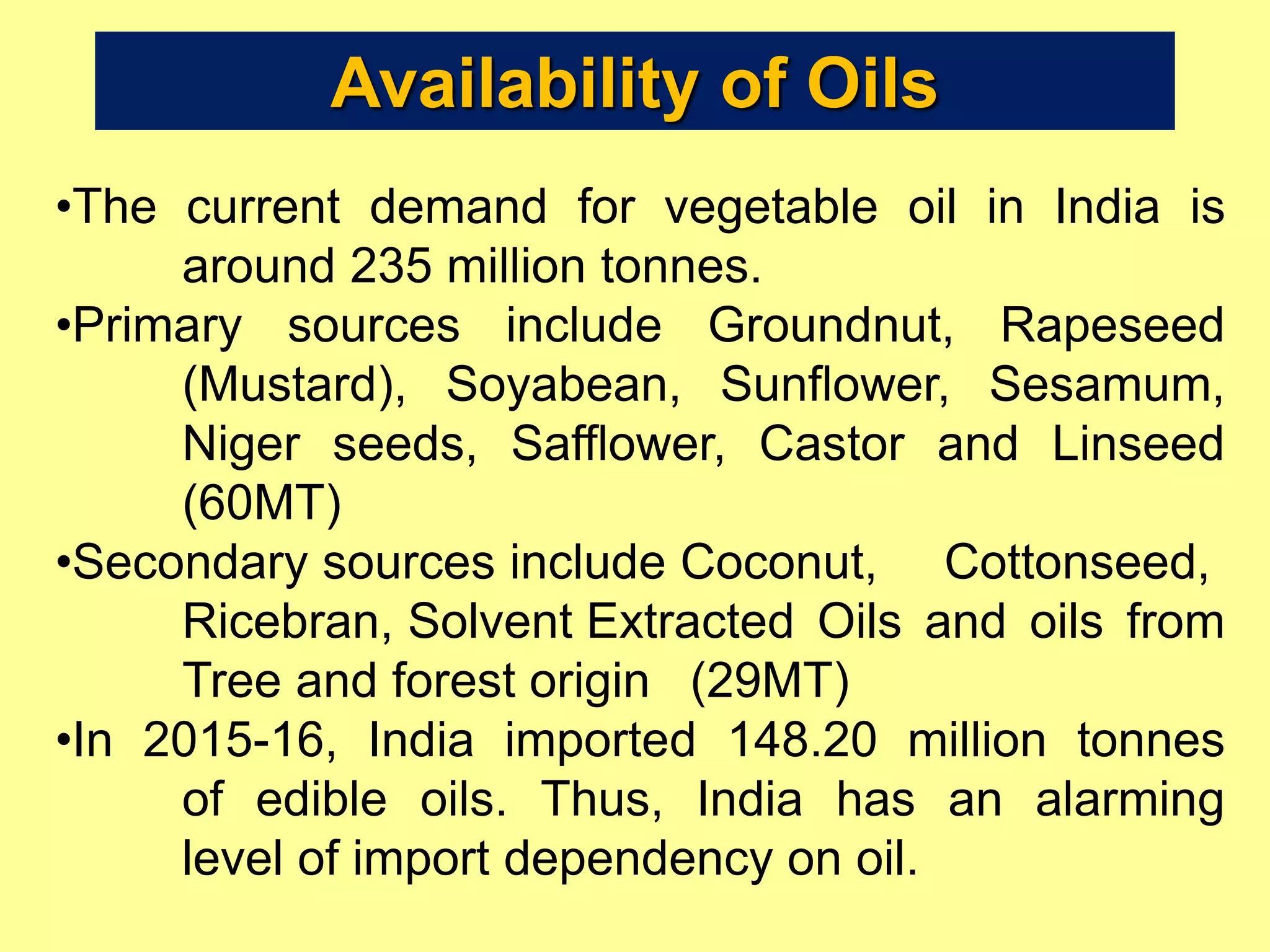

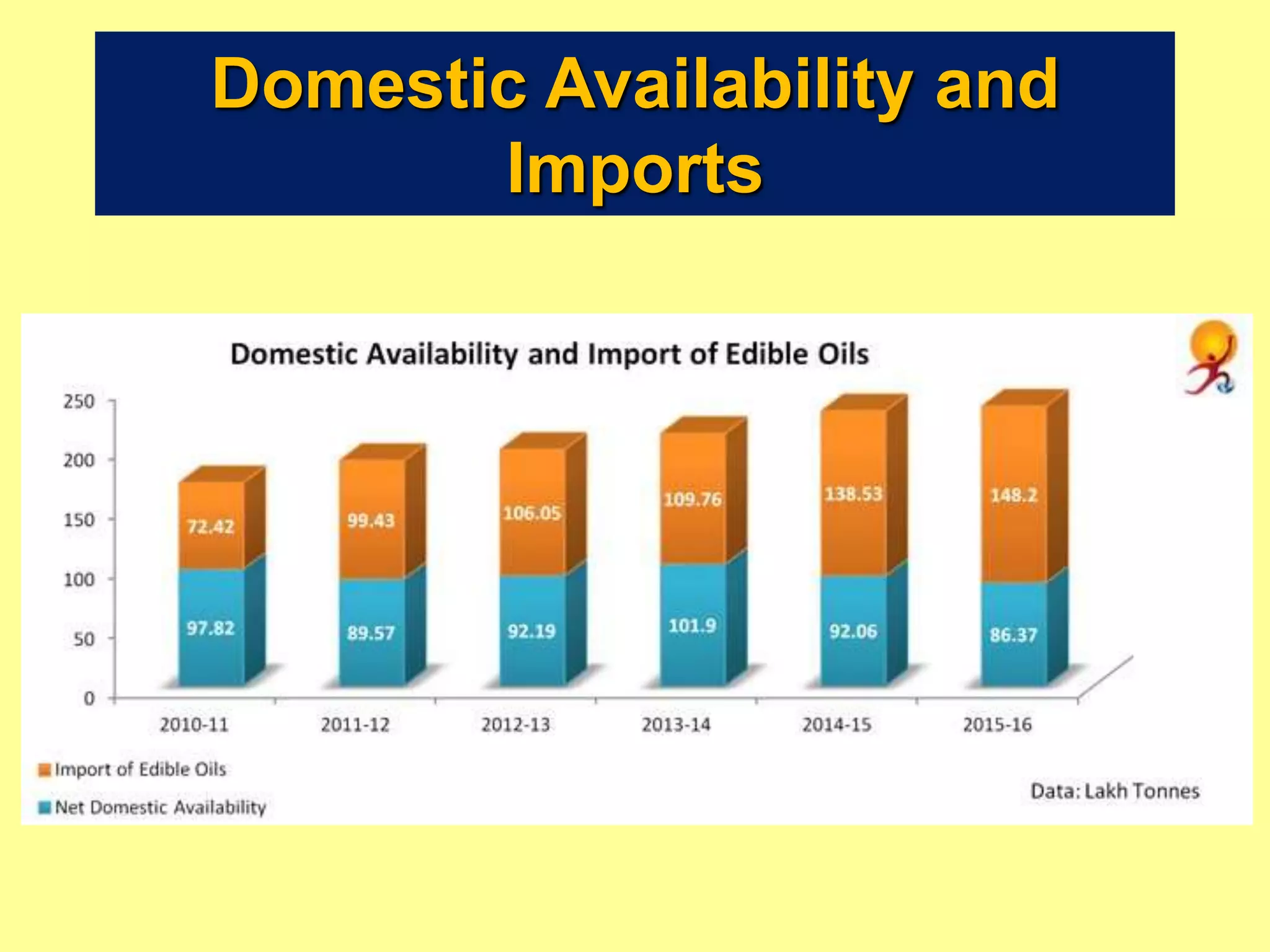

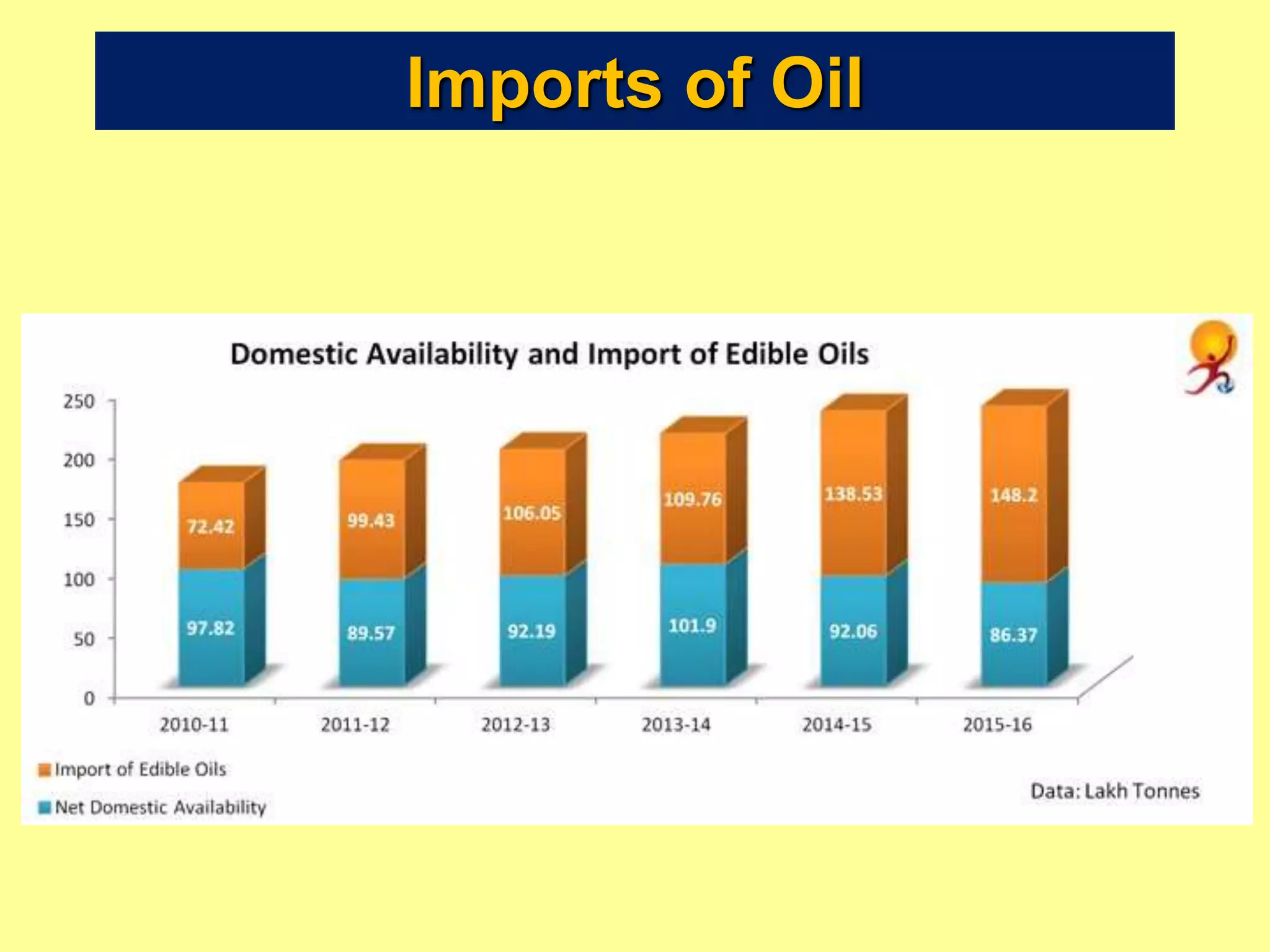

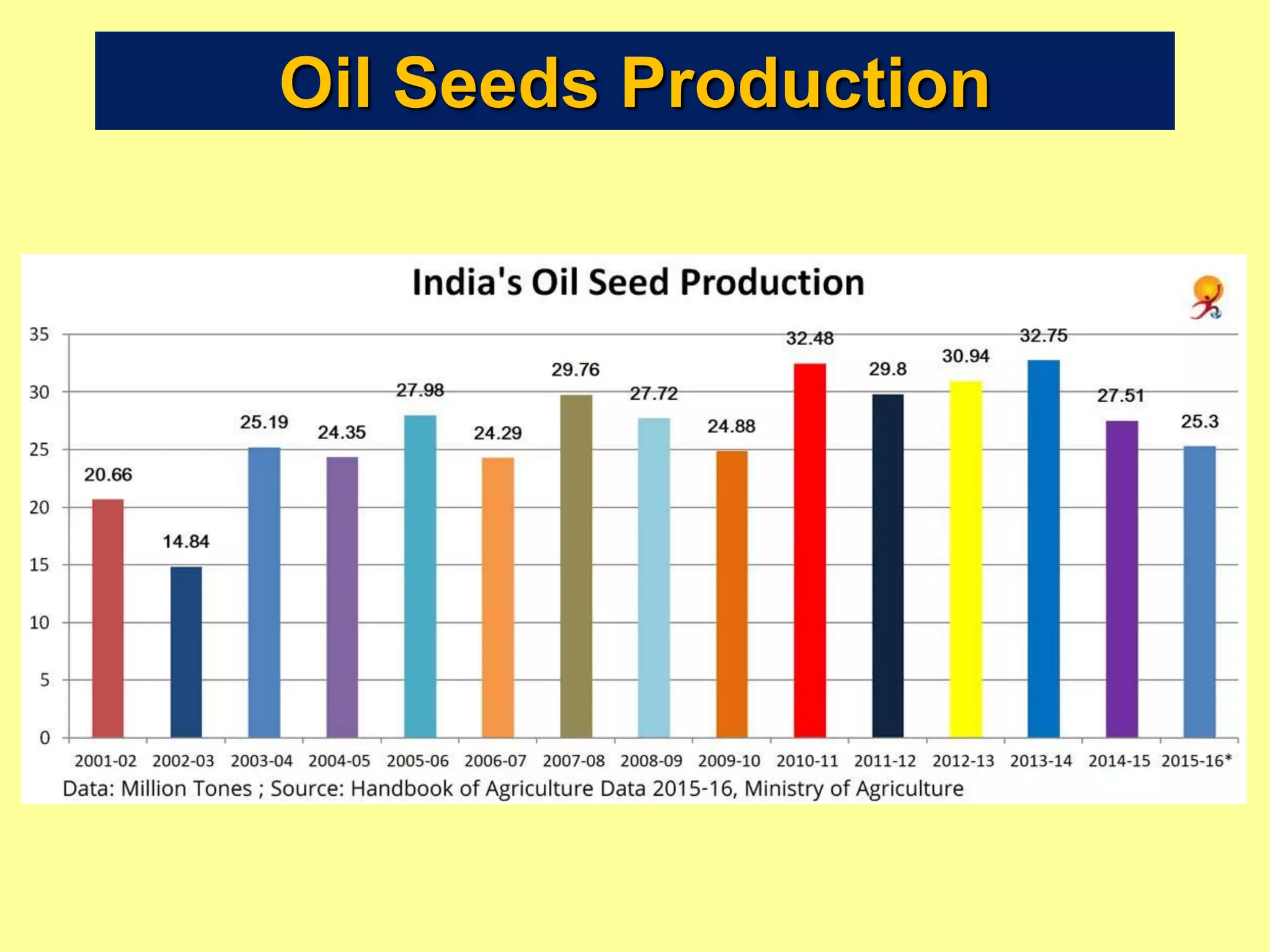

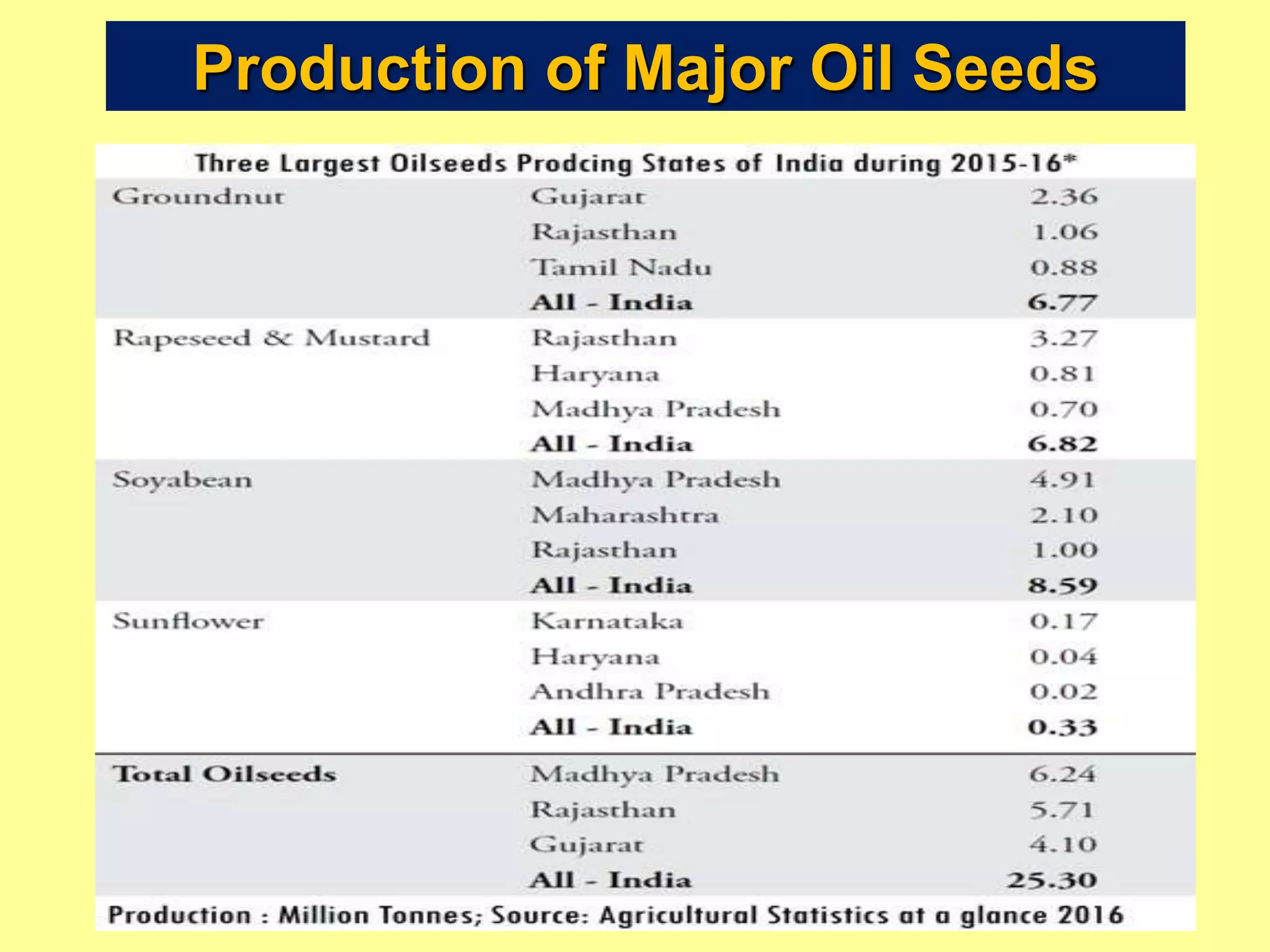

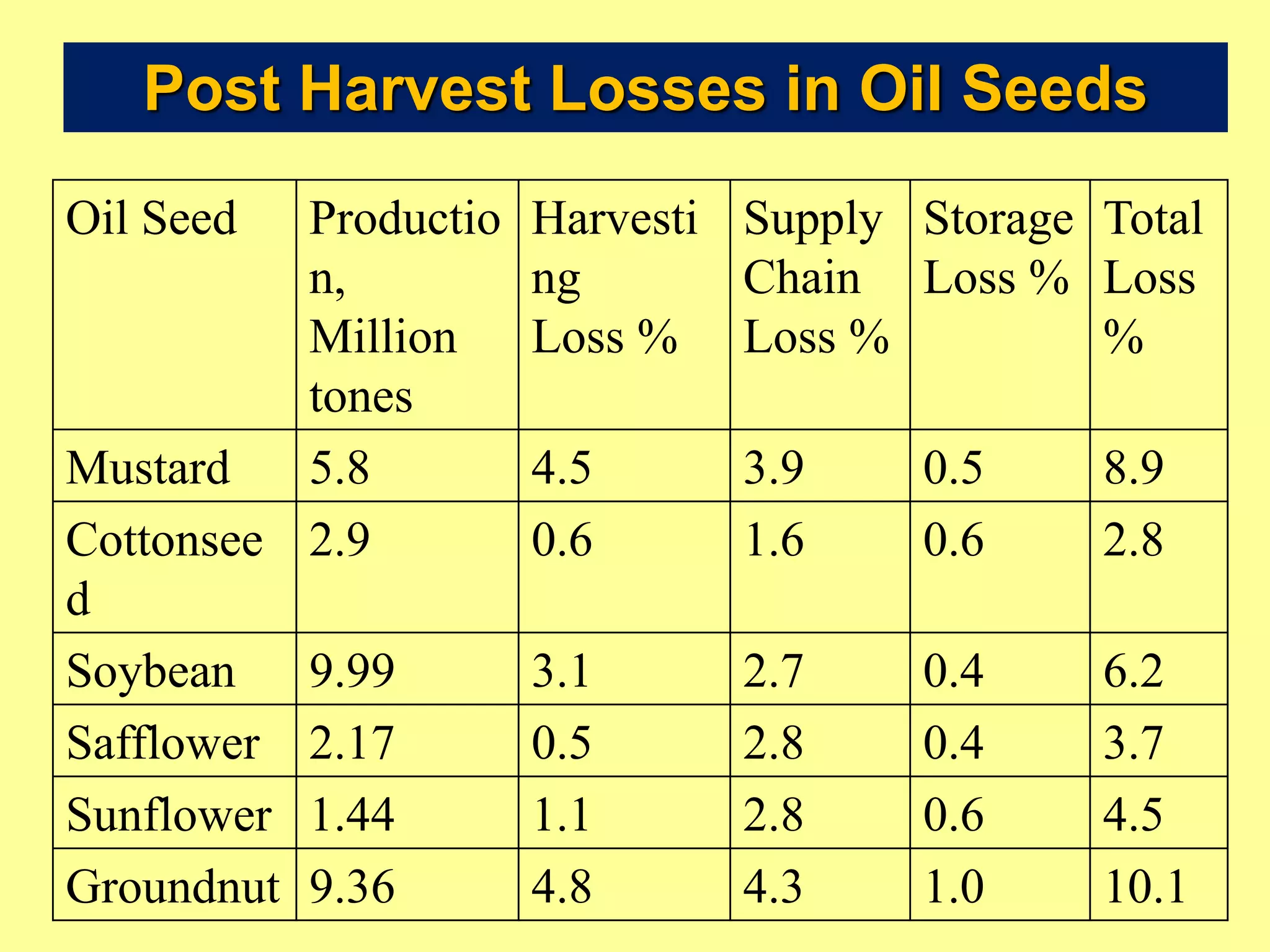

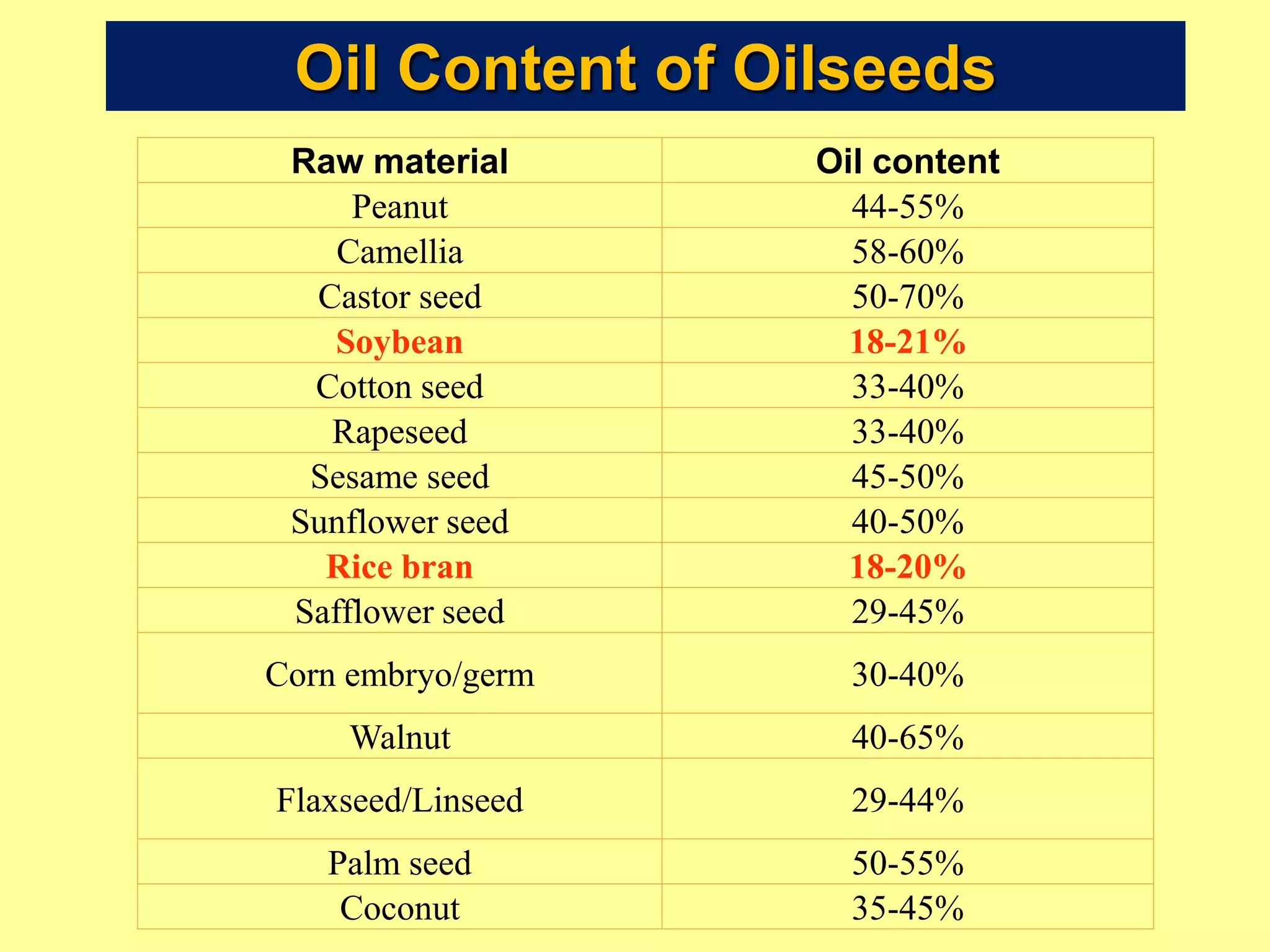

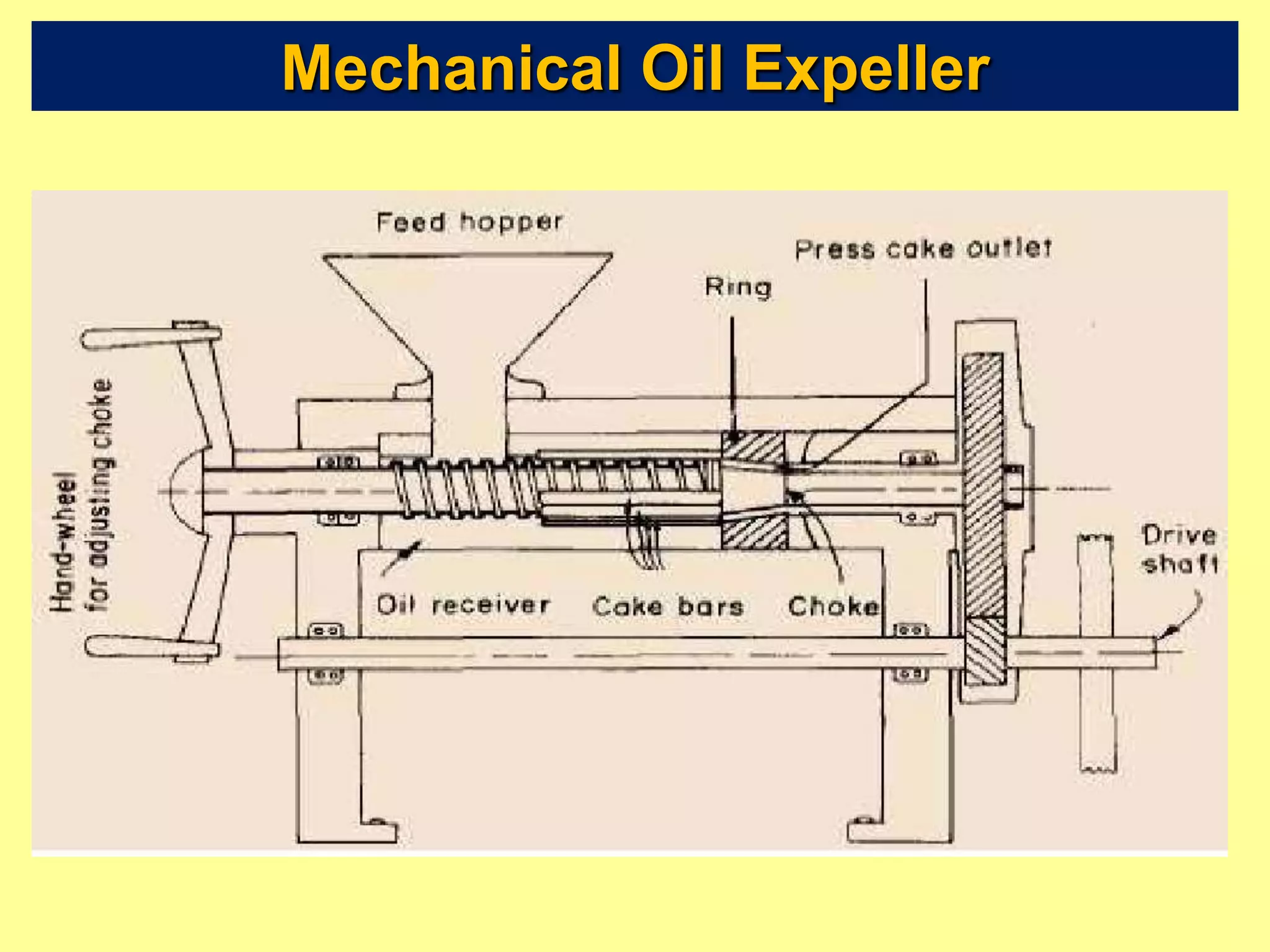

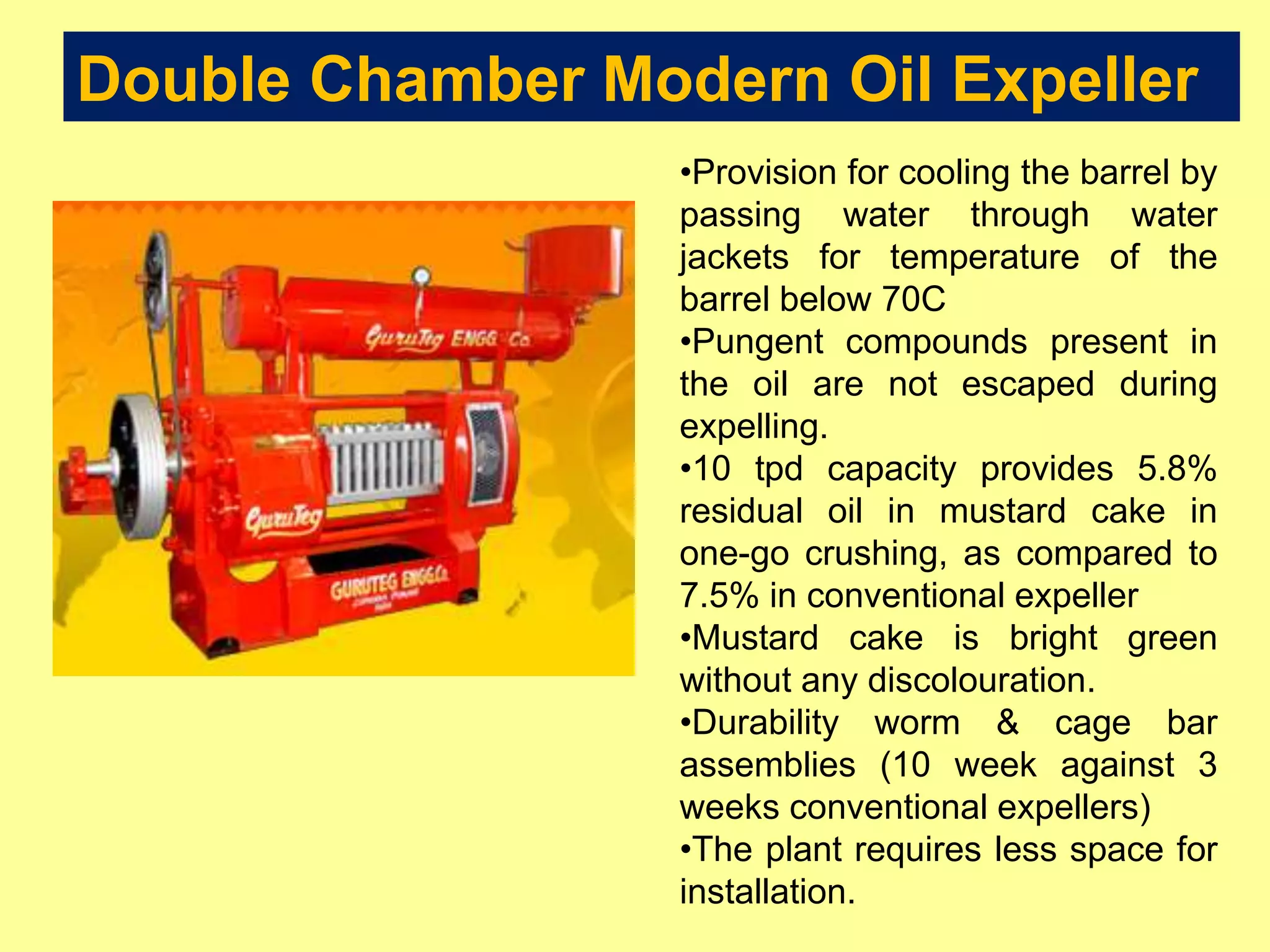

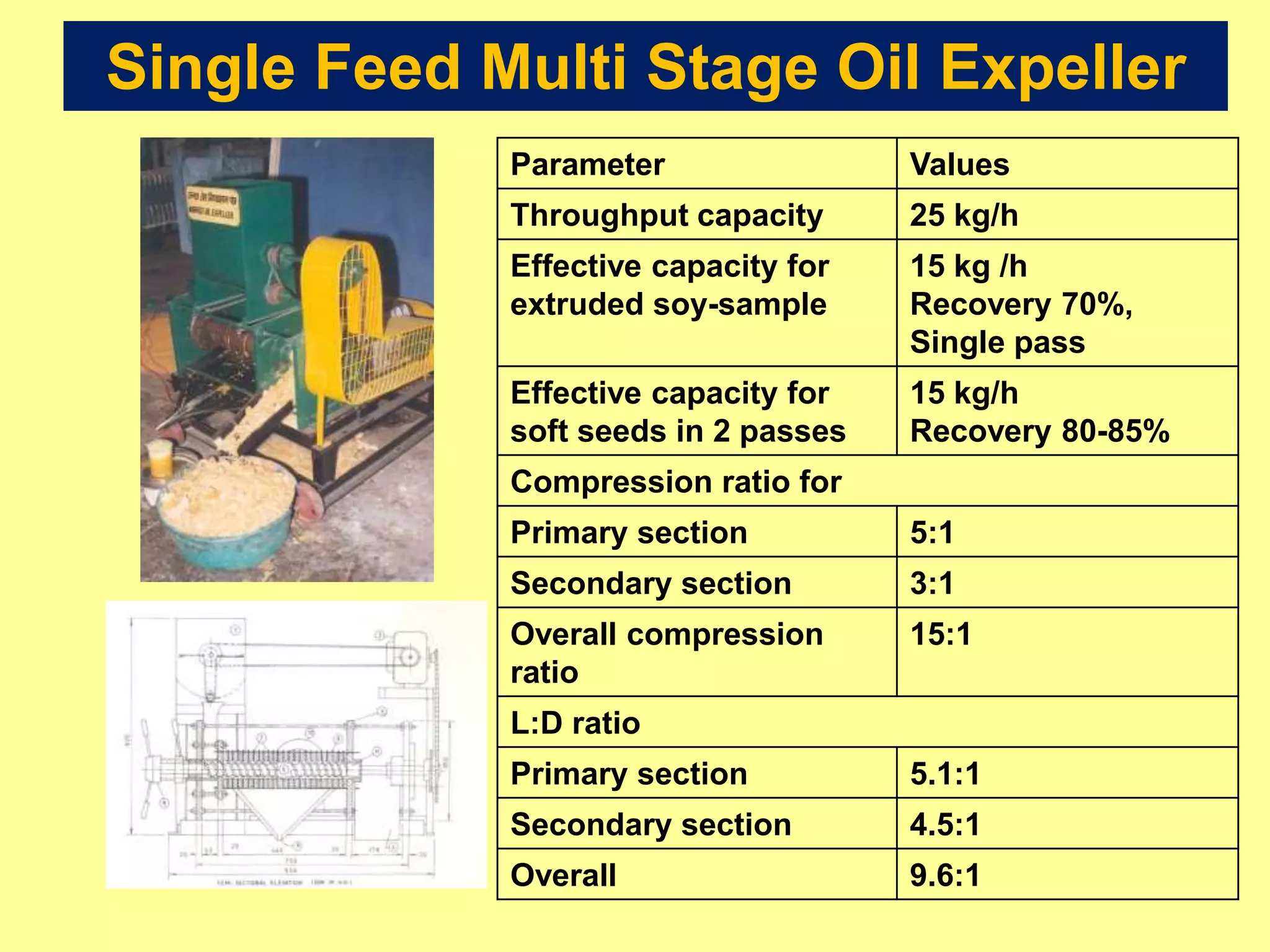

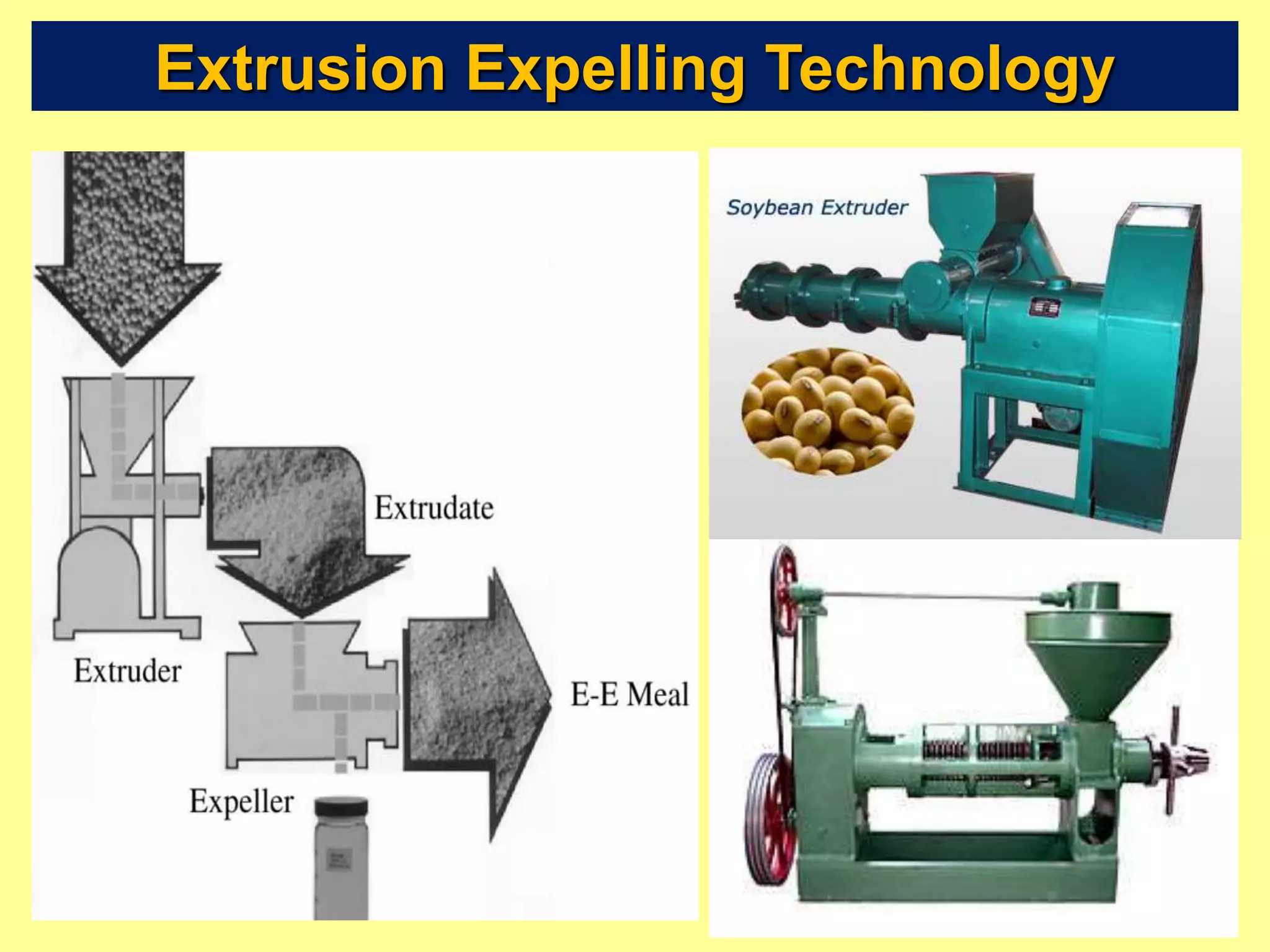

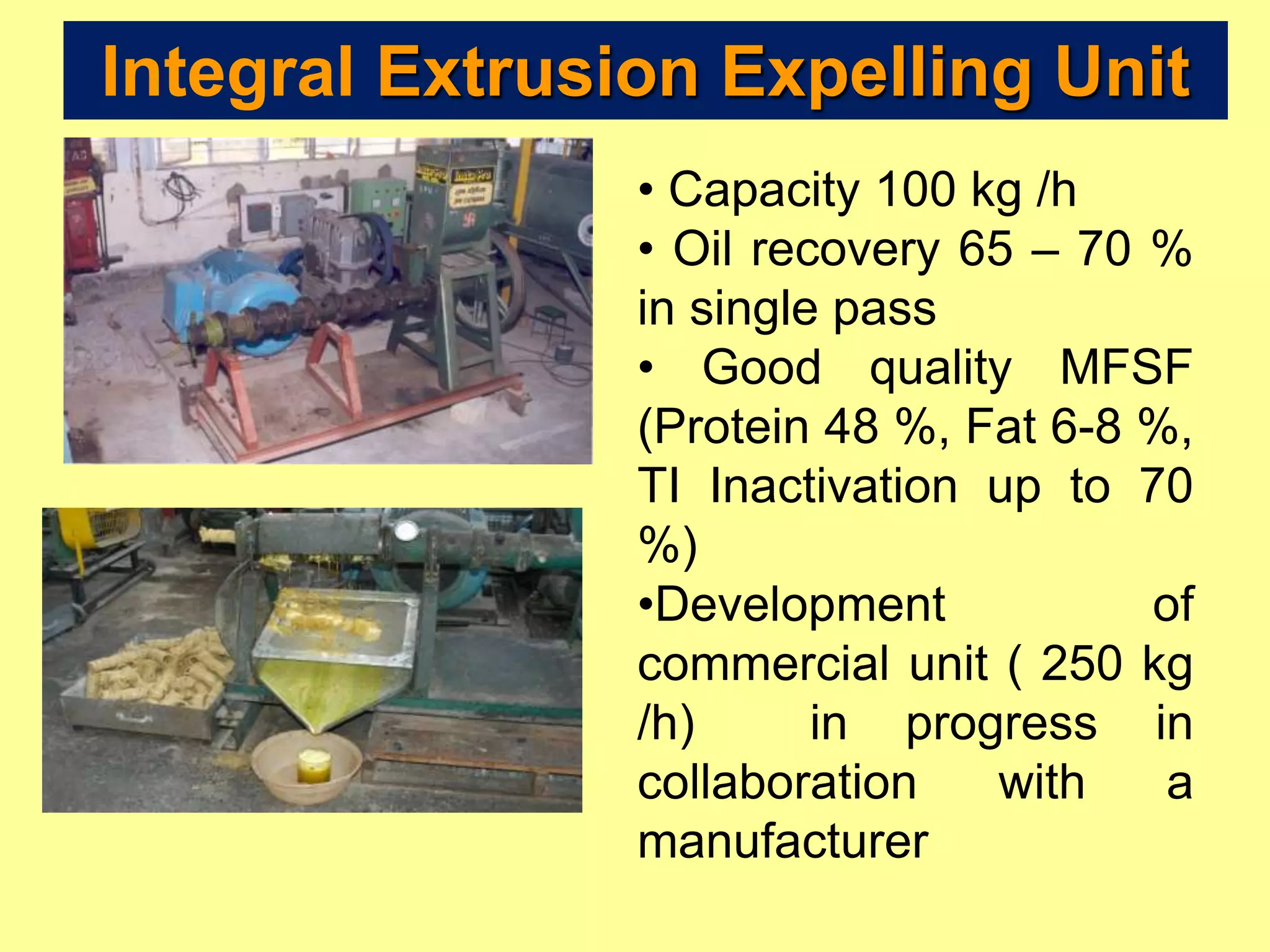

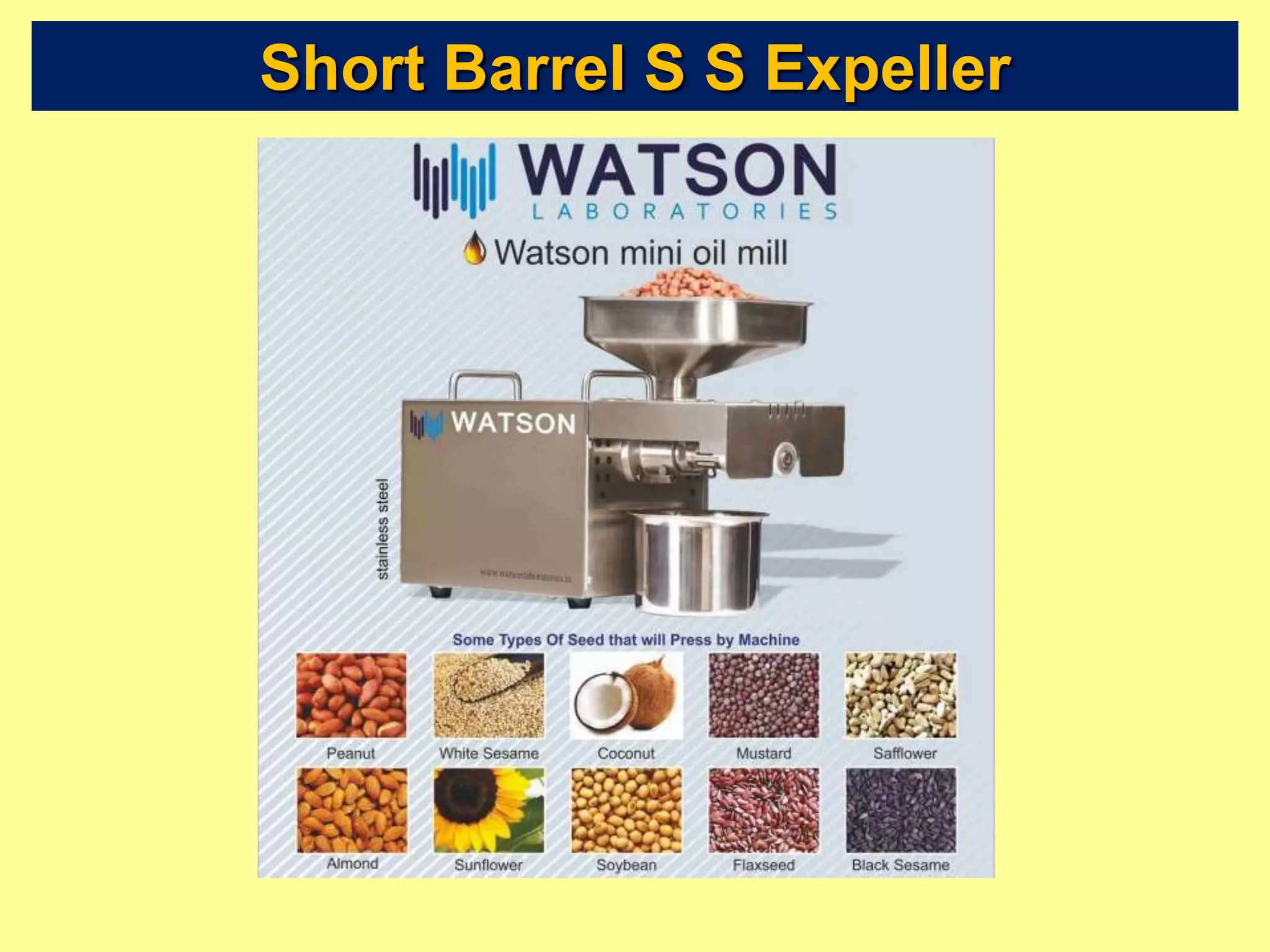

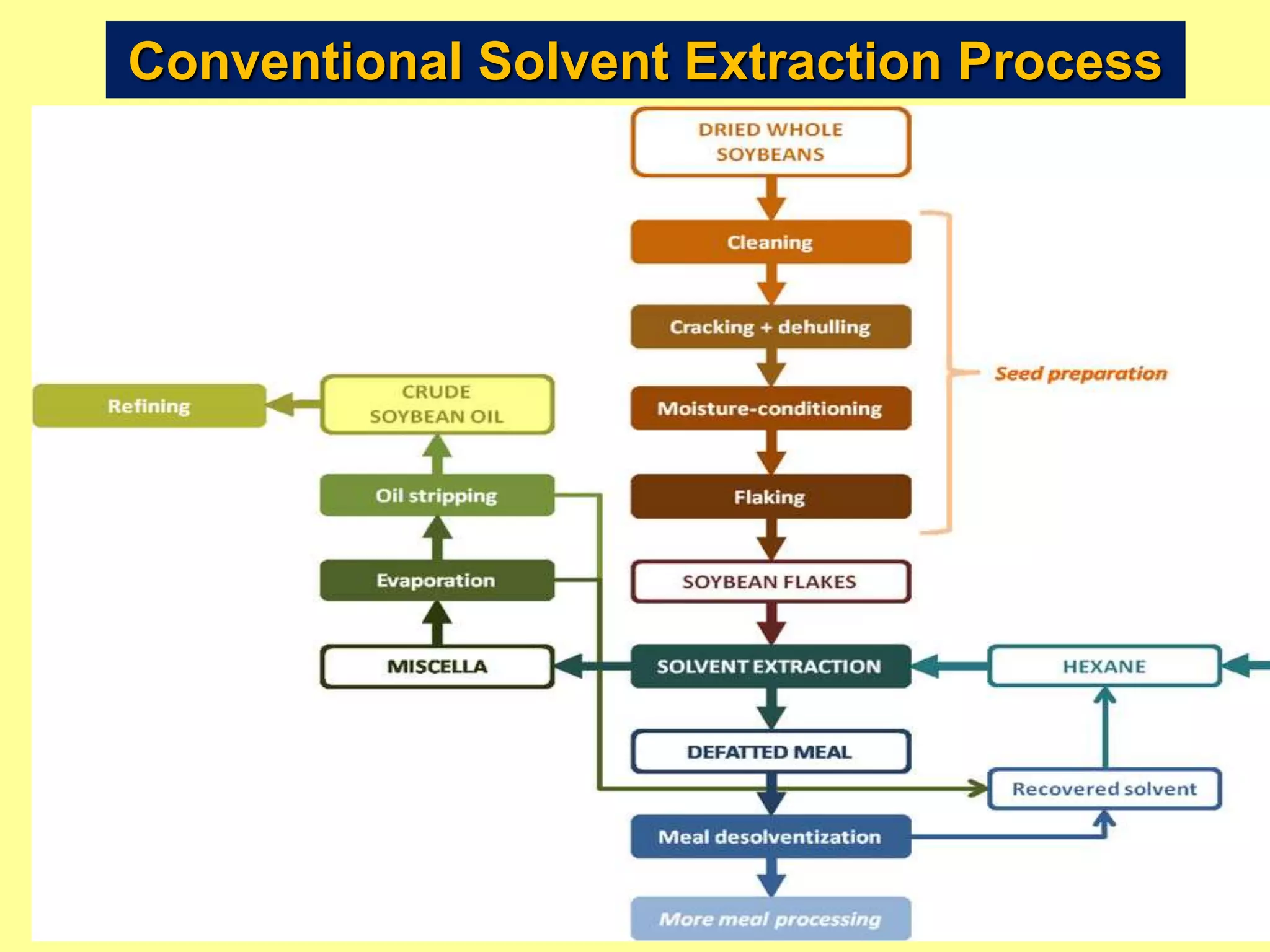

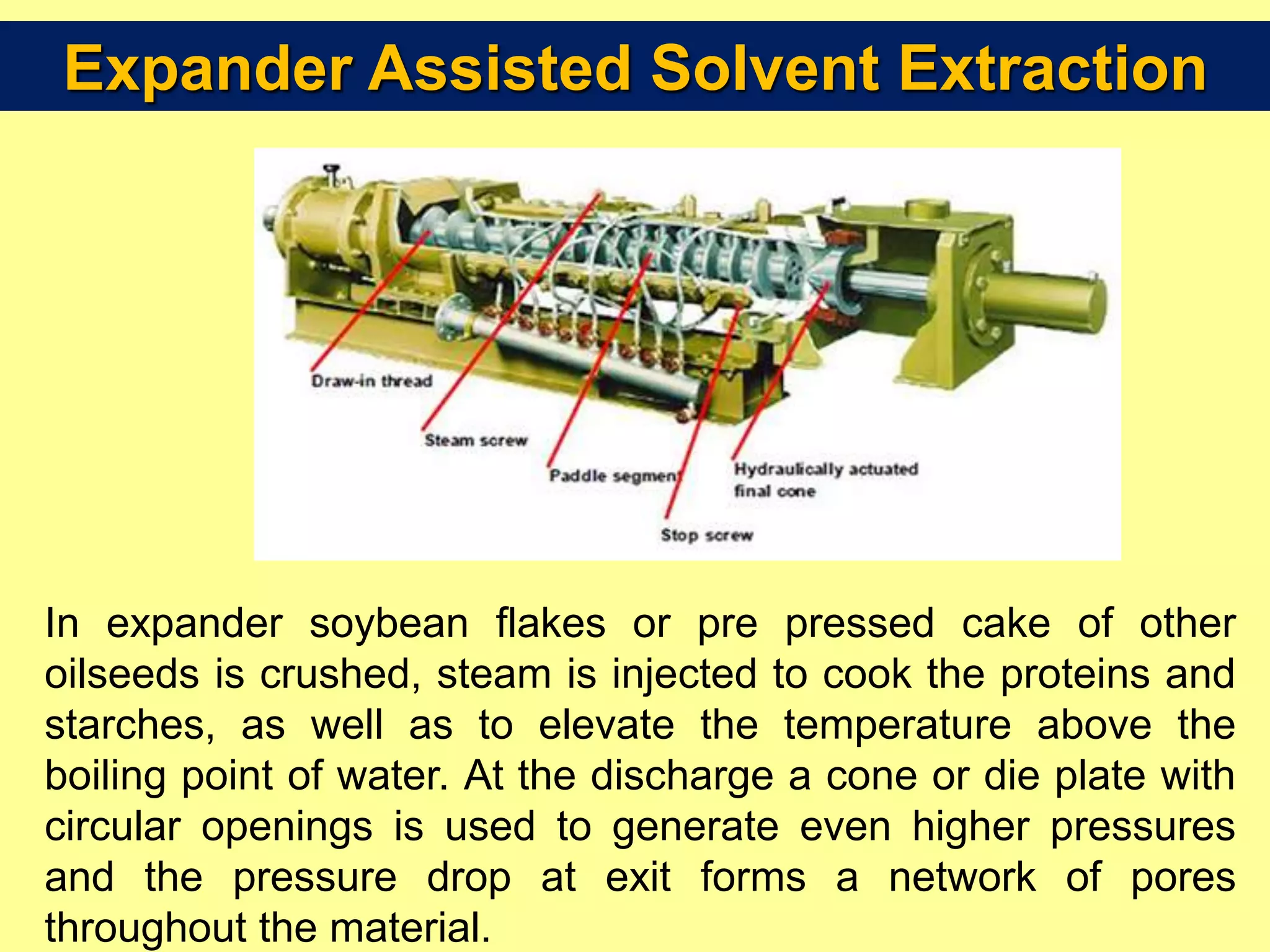

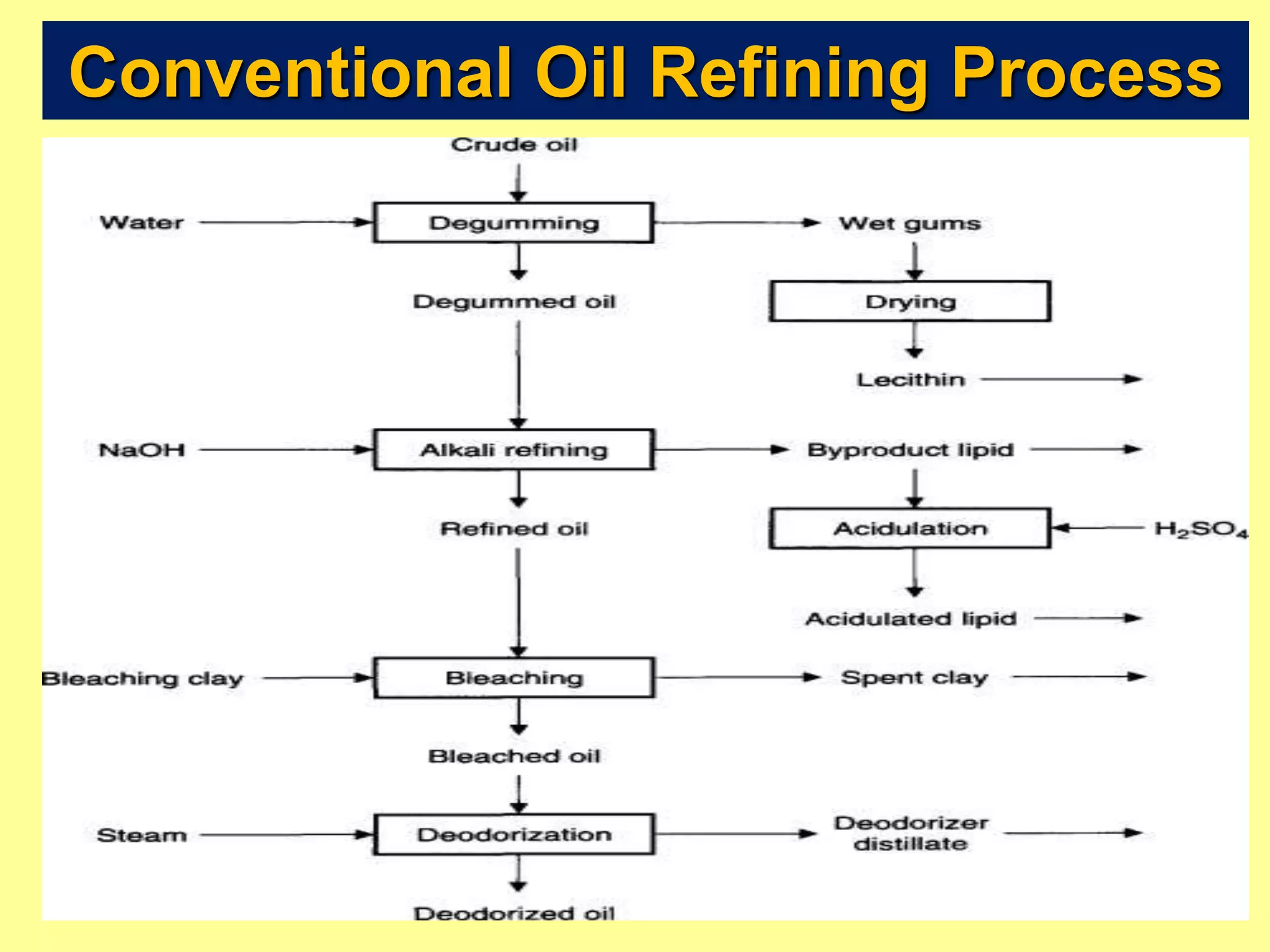

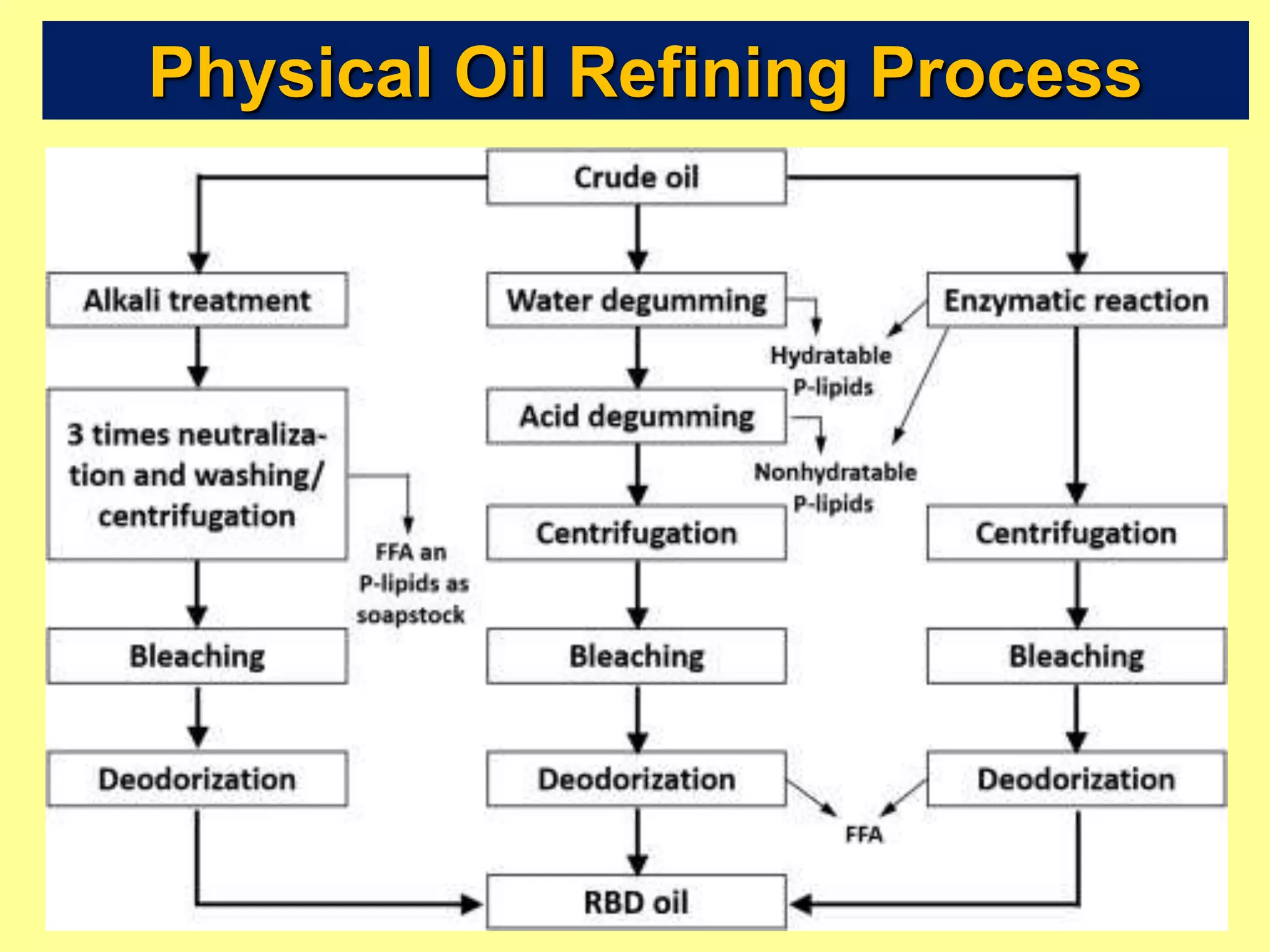

The document discusses advances in oil seed processing technologies in India. It summarizes India's current demand and domestic production of vegetable oils as well as import dependency. It then describes post-harvest losses for various oilseeds and their oil contents. The document proceeds to discuss smart interventions for oil extraction, including mechanical expression, solvent extraction, and various assisted solvent extraction methods like enzyme-assisted, ultrasound-assisted, microwave-assisted, and supercritical fluid extraction. It concludes by emphasizing the need for modernizing oil milling technologies in India to improve oil recovery and quality.