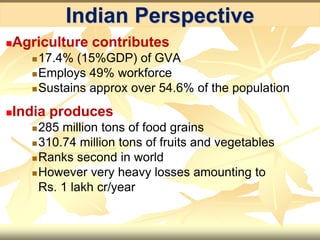

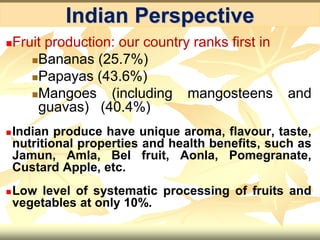

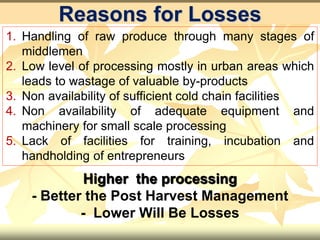

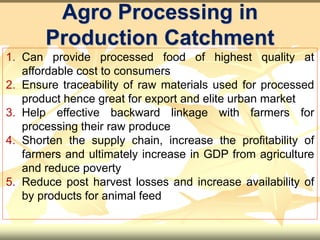

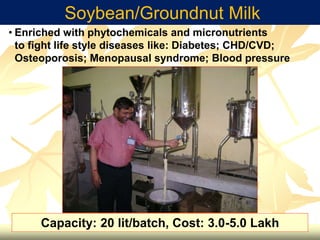

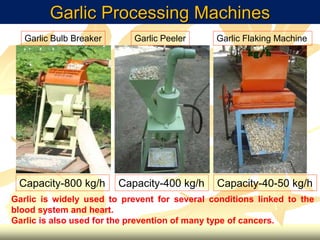

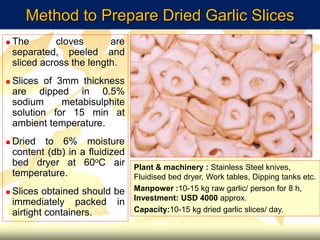

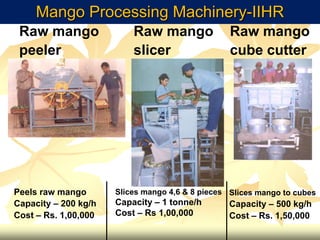

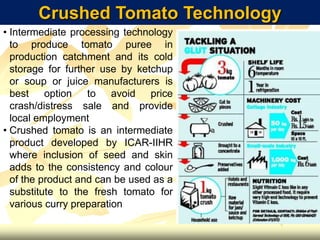

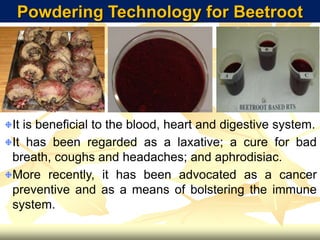

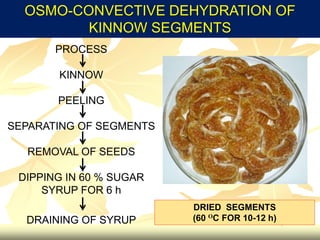

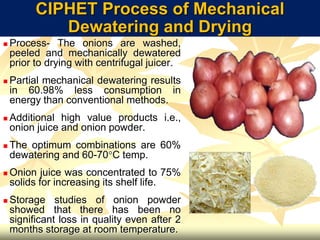

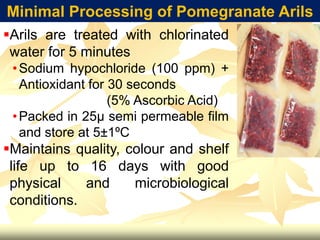

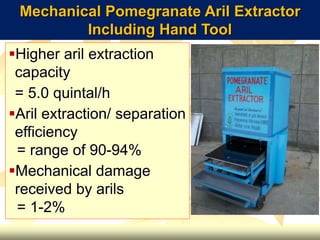

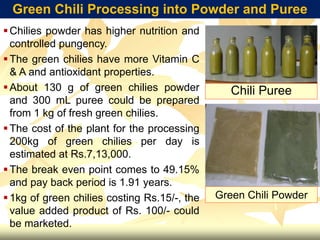

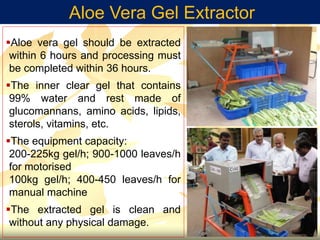

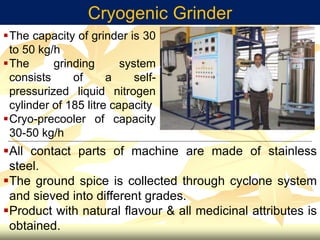

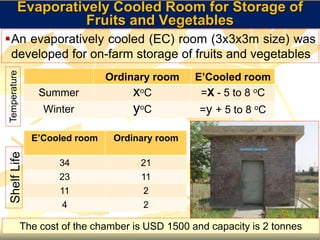

Indian agriculture contributes significantly to GDP and employment, but there are also heavy post-harvest losses of food. There are opportunities for entrepreneurs in food processing to help reduce these losses through technologies like soy milk production, garlic and mango processing equipment, moringa and beetroot powdering, tomato puree production, and pomegranate and aloe vera gel extraction. Adopting techniques like evaporative cooling and cryogenic grinding can further help small processors improve food storage and quality. With appropriate training and resources, food processing can benefit farmers, consumers, and the overall economy.