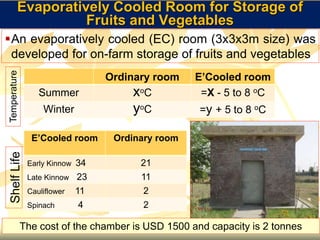

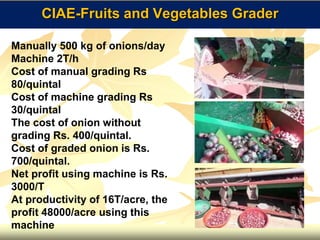

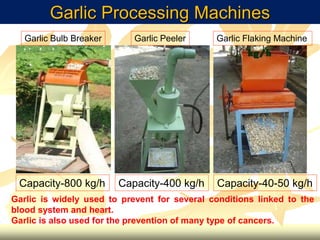

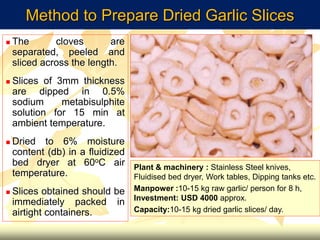

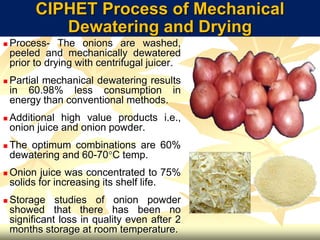

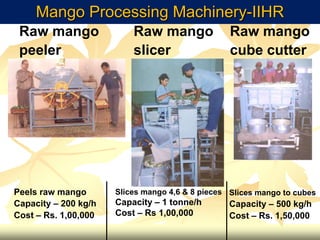

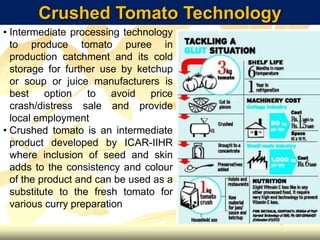

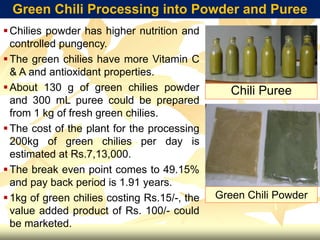

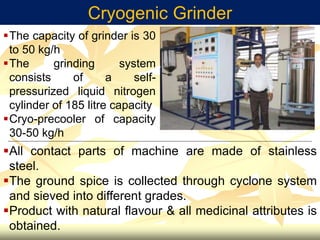

This document discusses food processing technologies that could help reduce post-harvest losses in Madhya Pradesh and generate employment. It outlines India's large production of food grains and fruits/vegetables but low level of processing at 10%. Technologies presented include an evaporatively cooled storage room, fruit/vegetable graders, garlic processing machines, onion dewatering and drying, mango cutting machines, crushed tomato processing, and green chili powder/puree production. It recommends developing rural agro processing centers, infrastructure for sorting/packaging/storage, and facilitating direct marketing to reduce losses and support micro enterprises.