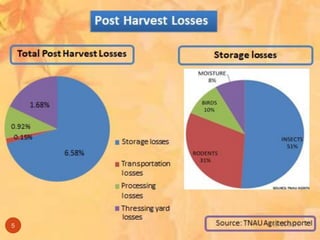

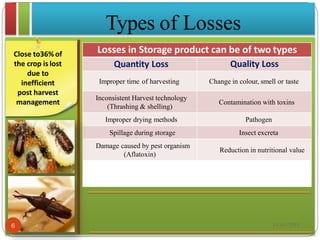

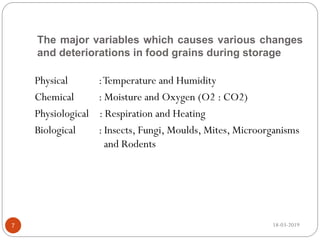

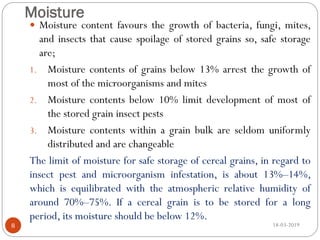

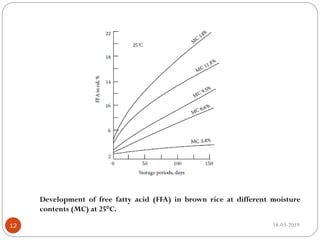

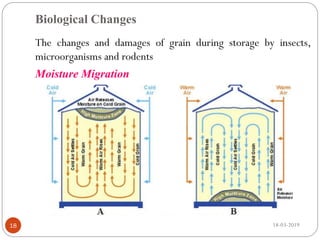

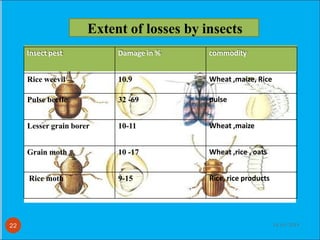

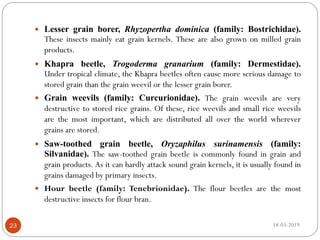

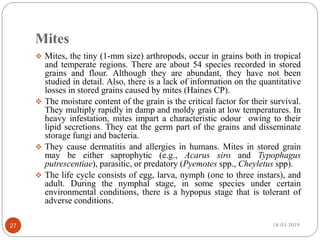

The document discusses grain quality deterioration during storage, emphasizing post-harvest losses and the factors contributing to these changes, including moisture content, temperature, and biological activities from pests and microorganisms. It highlights how improper storage conditions can lead to both quantitative and qualitative losses, affecting grain viability and safety for consumption. The text also outlines the importance of controlling pests and storage conditions to mitigate deterioration and maintain grain quality.