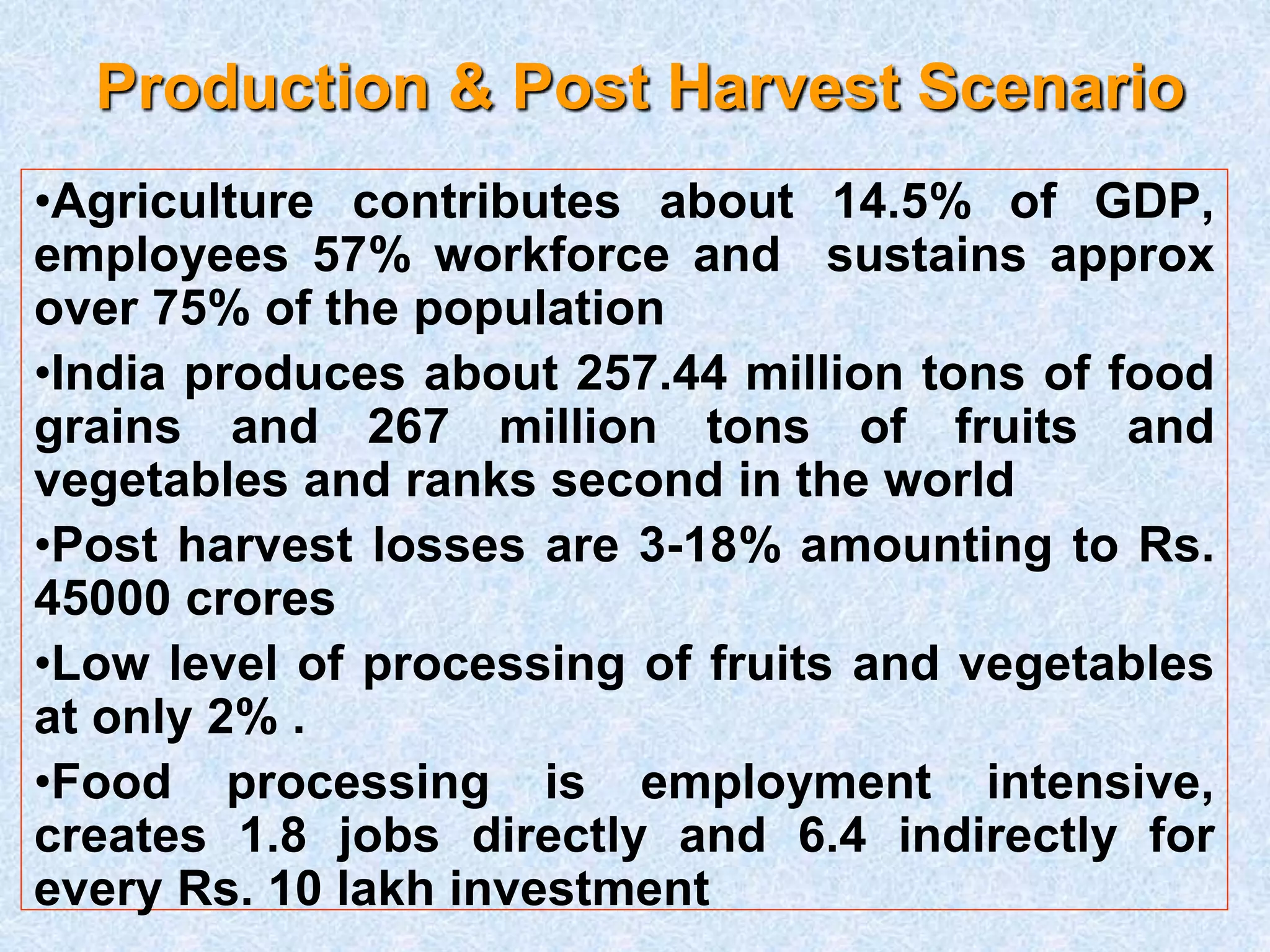

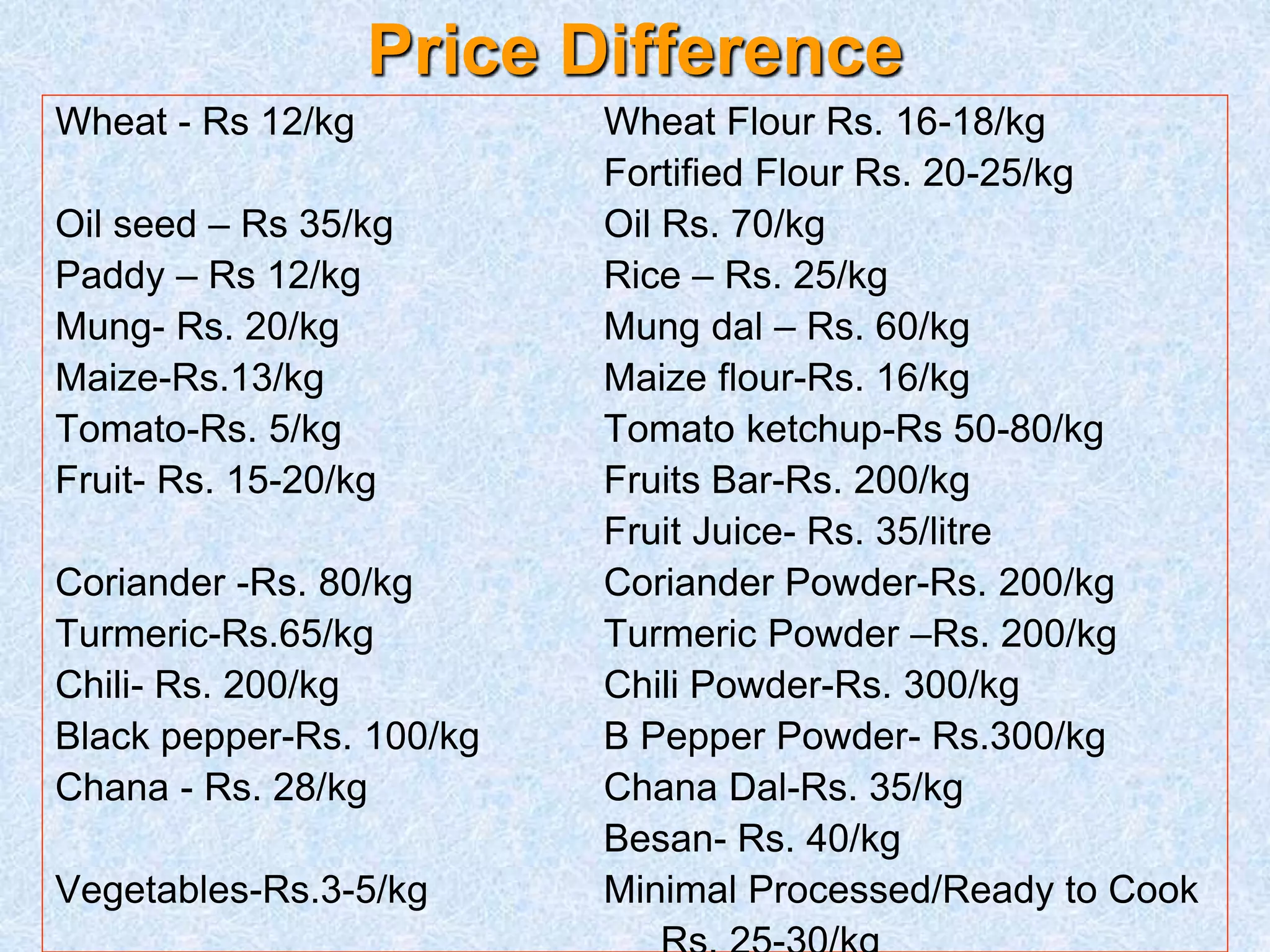

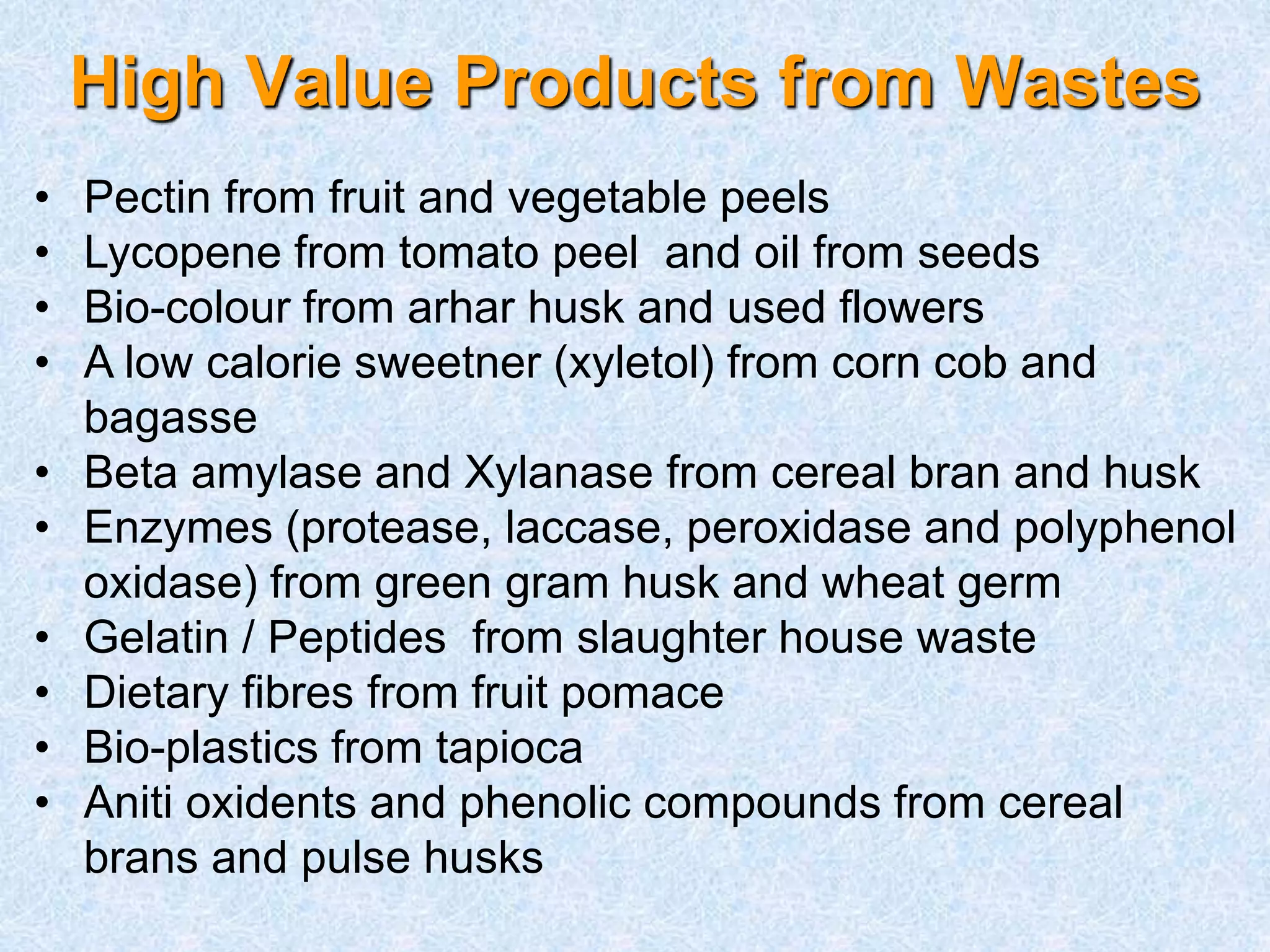

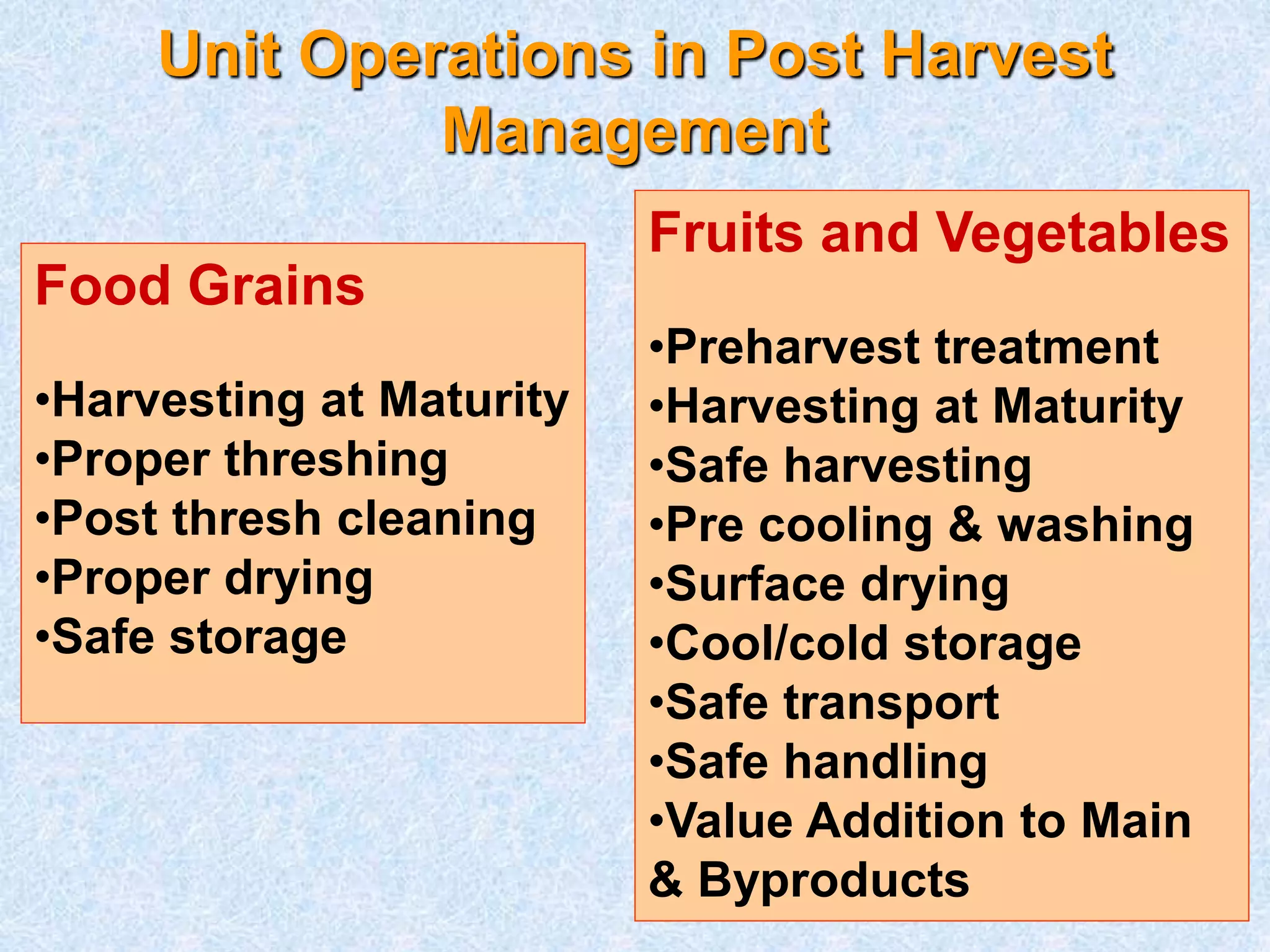

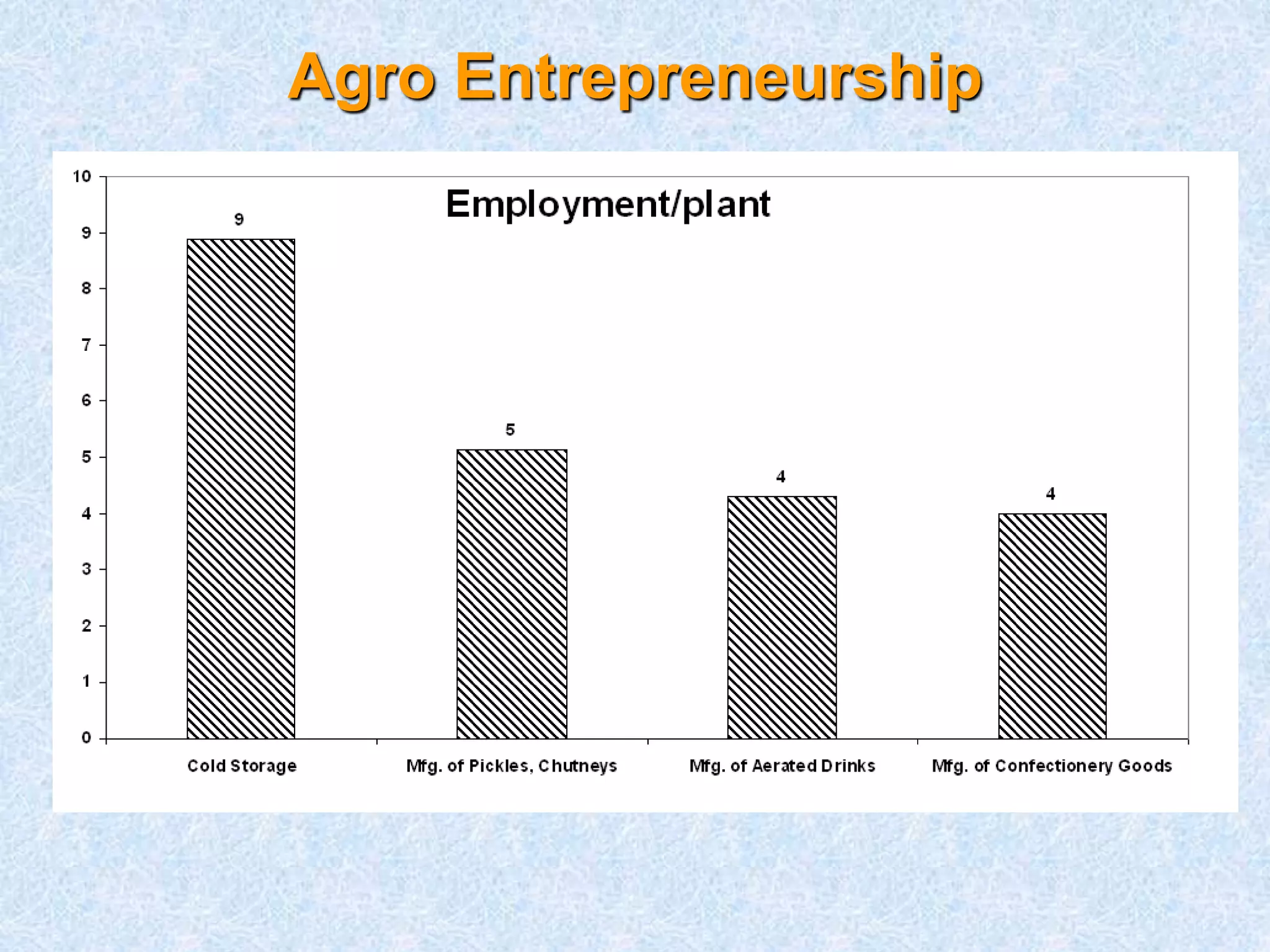

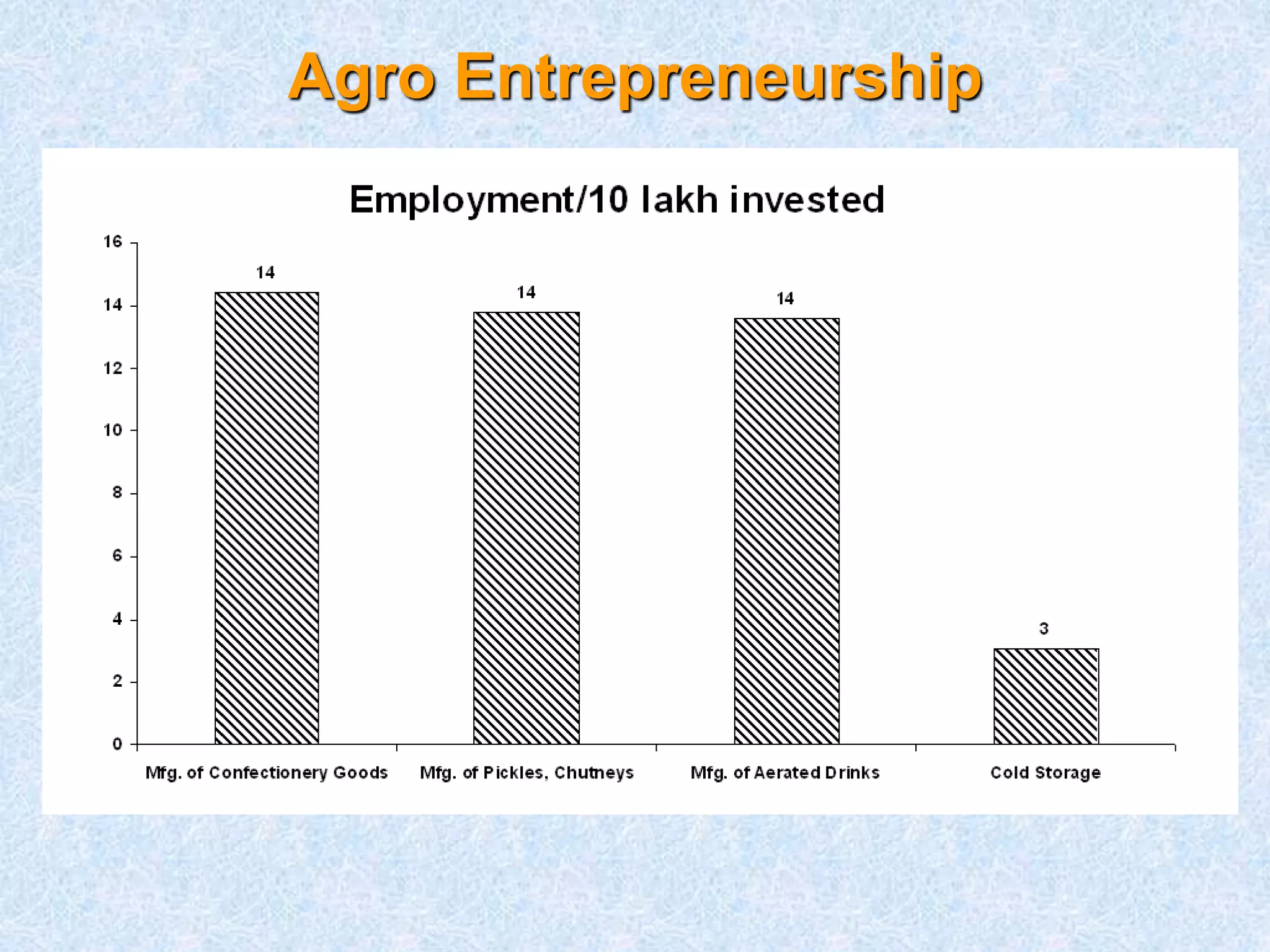

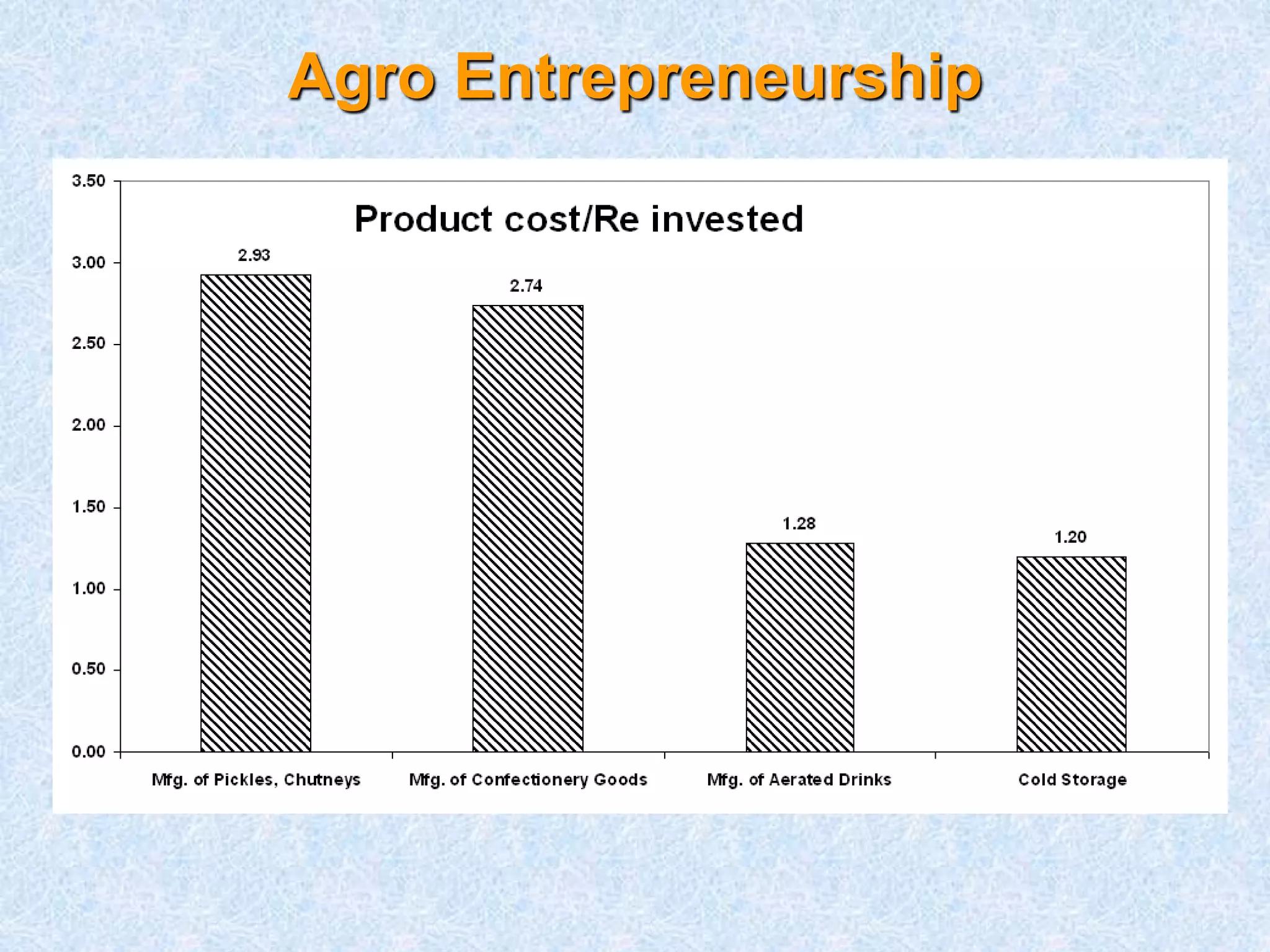

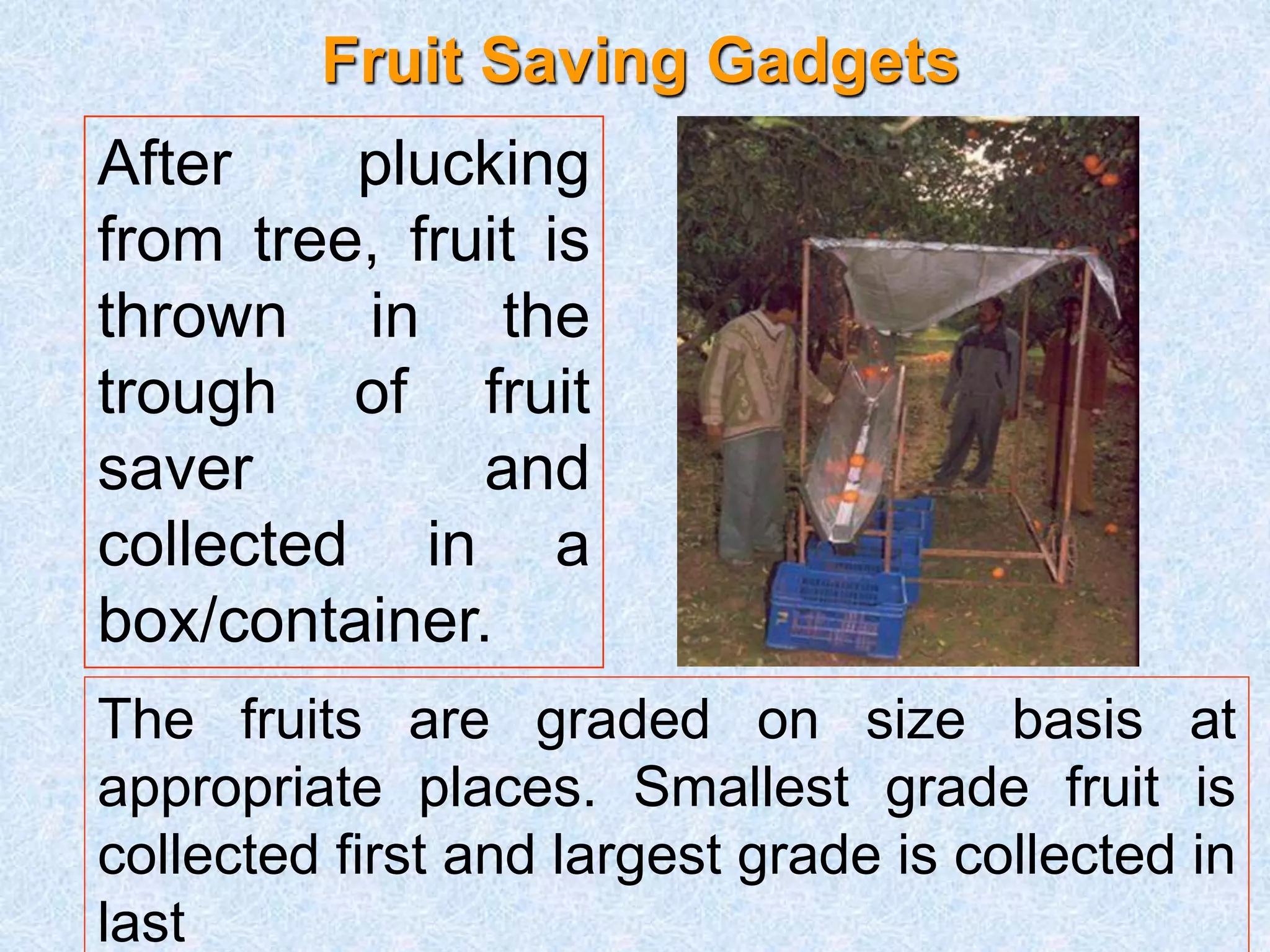

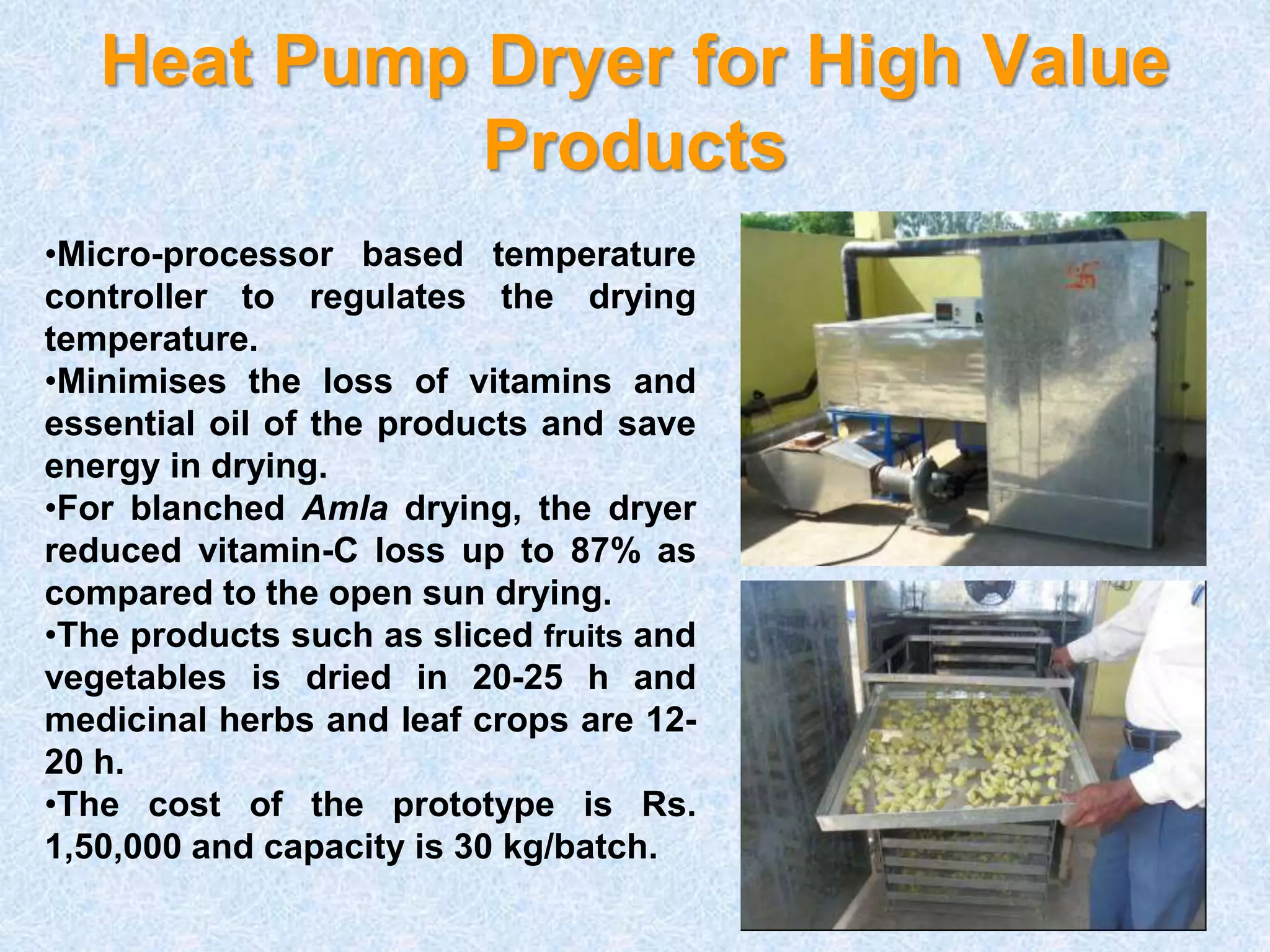

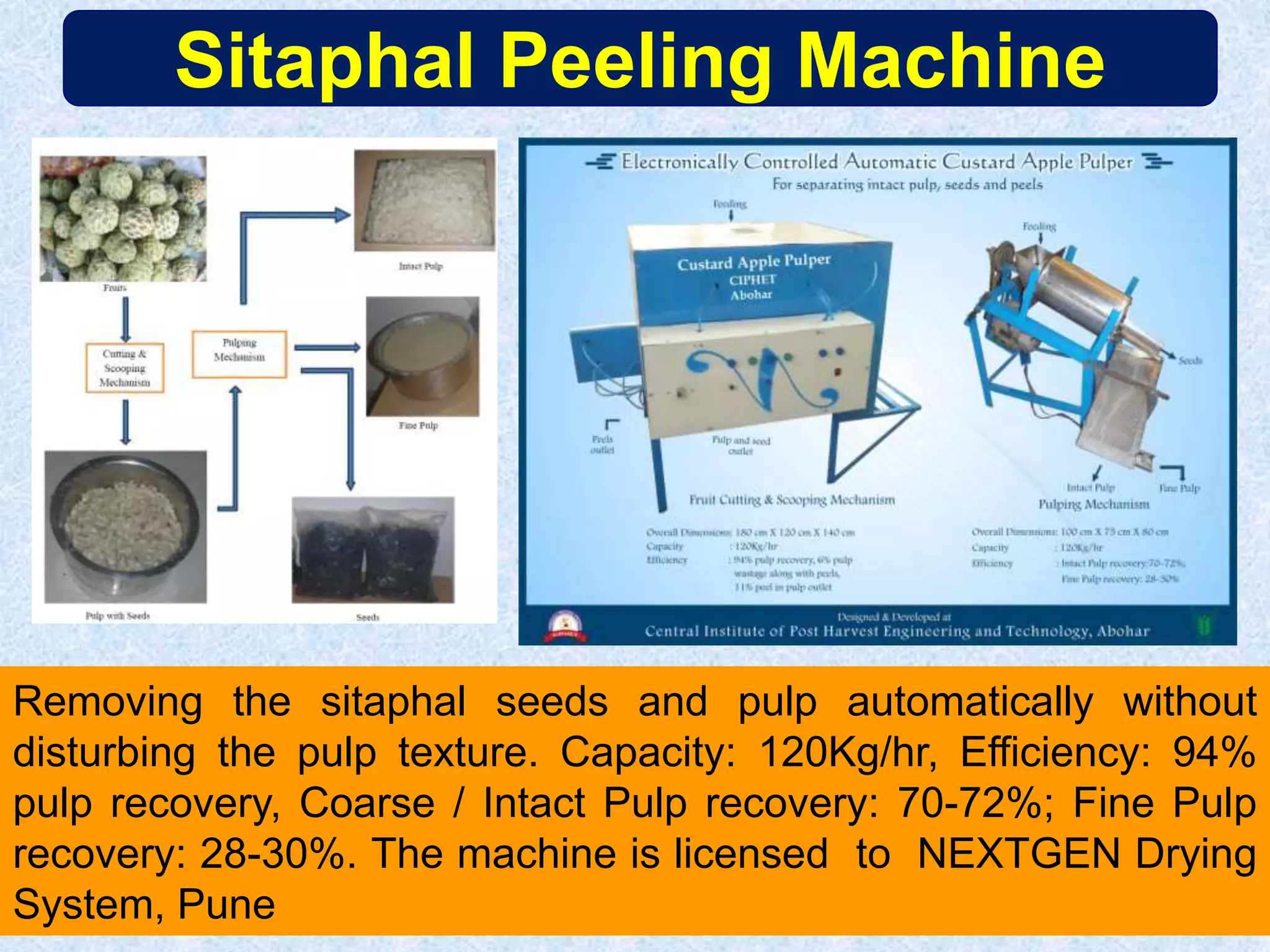

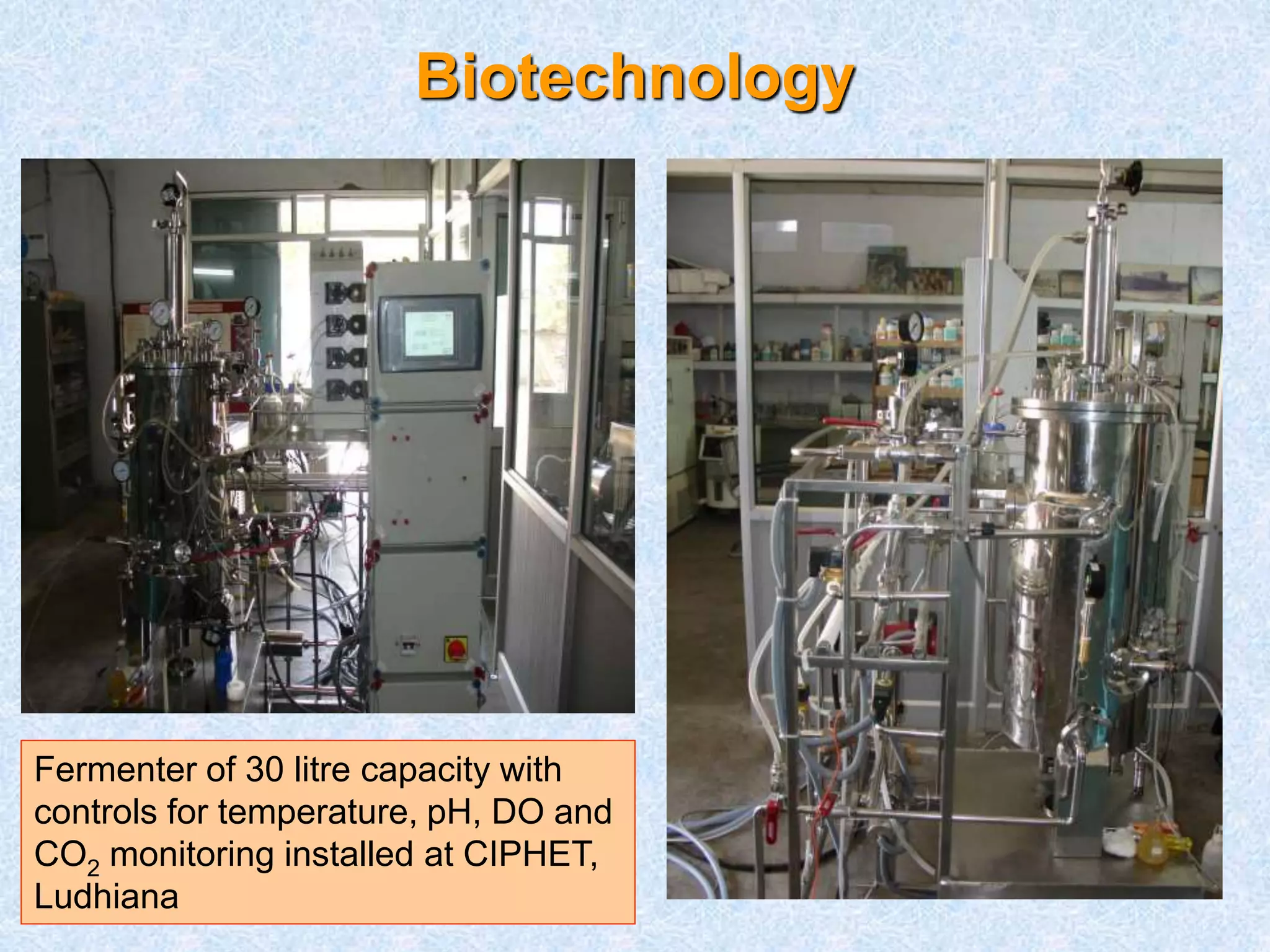

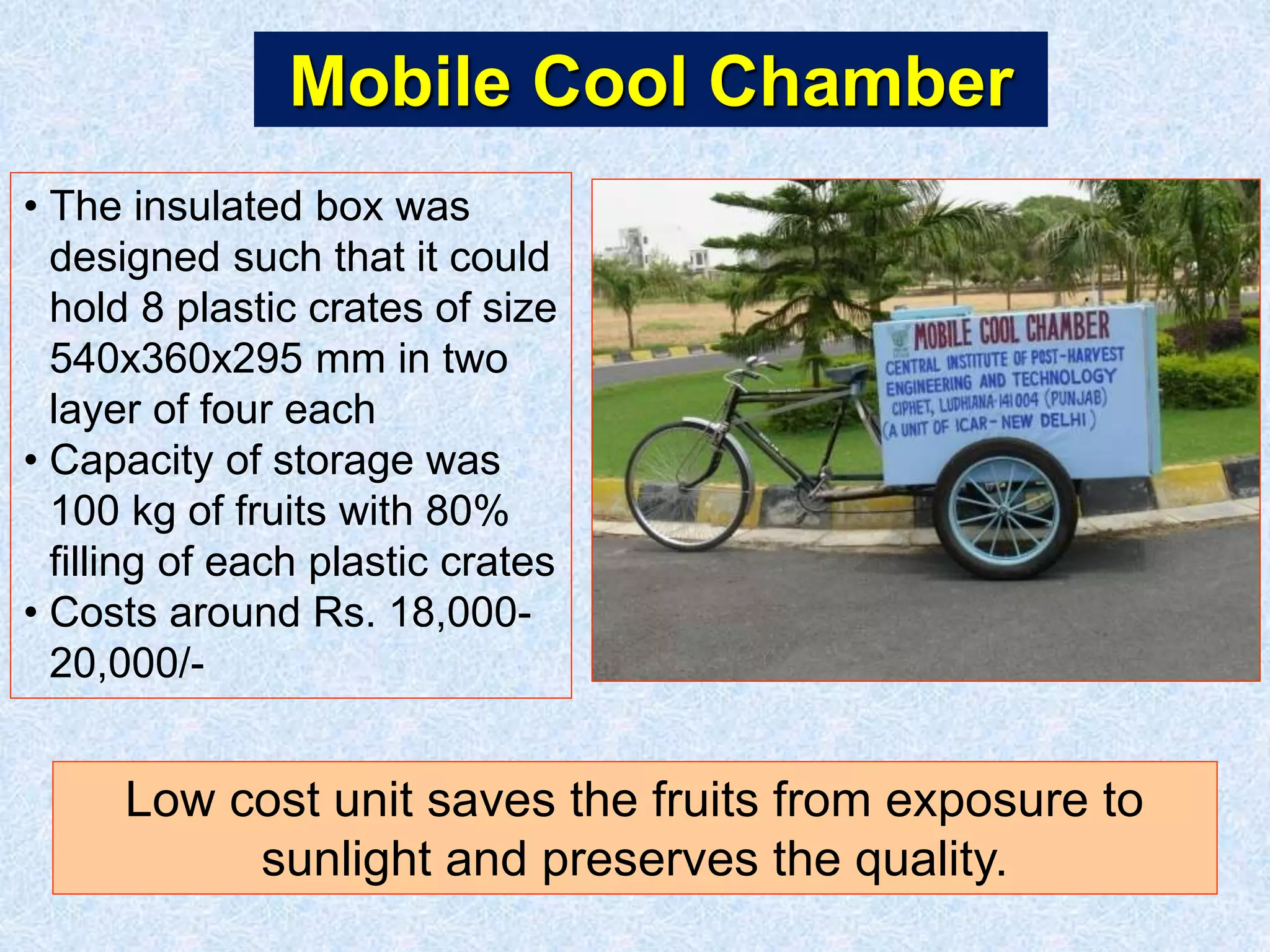

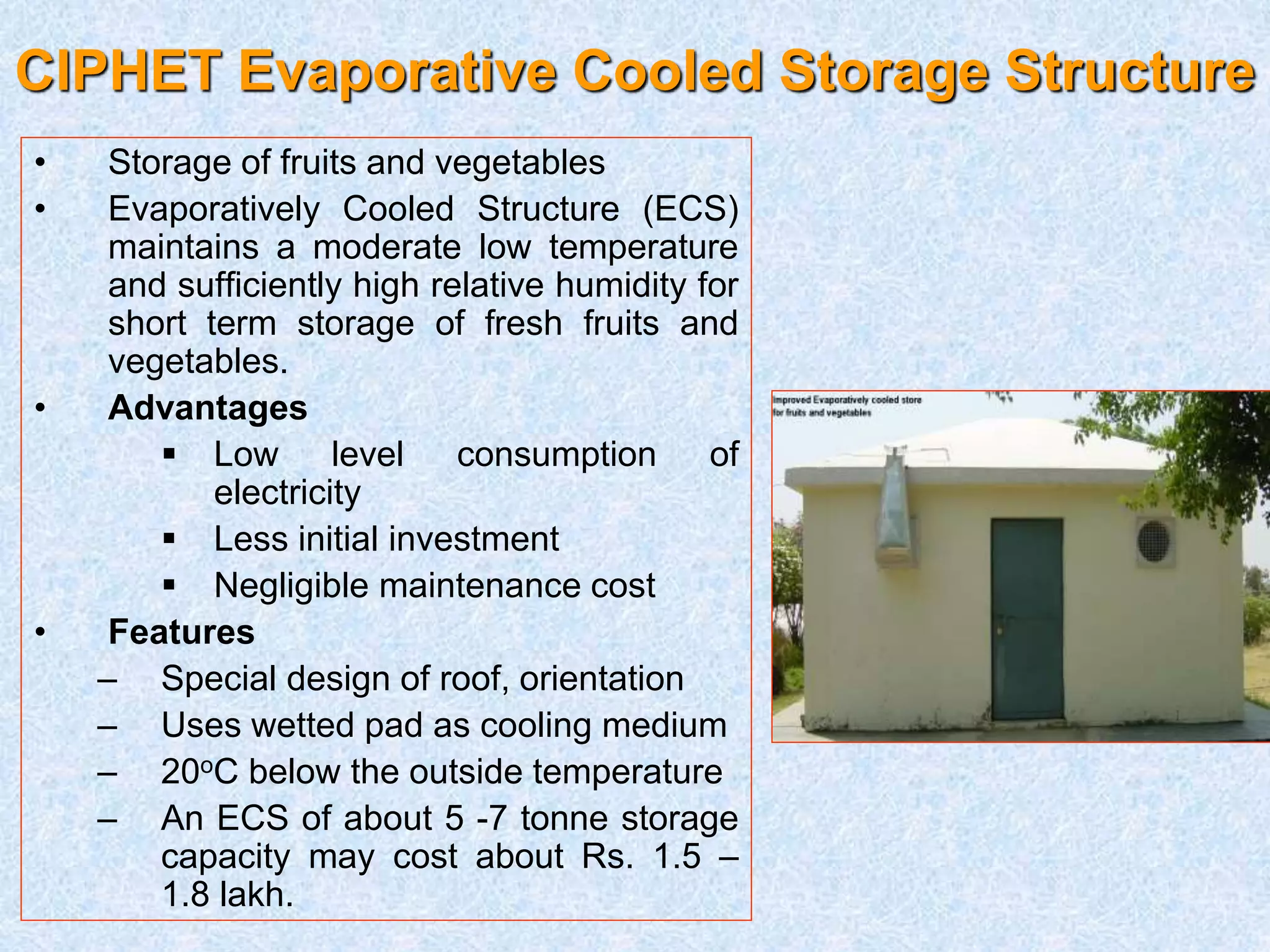

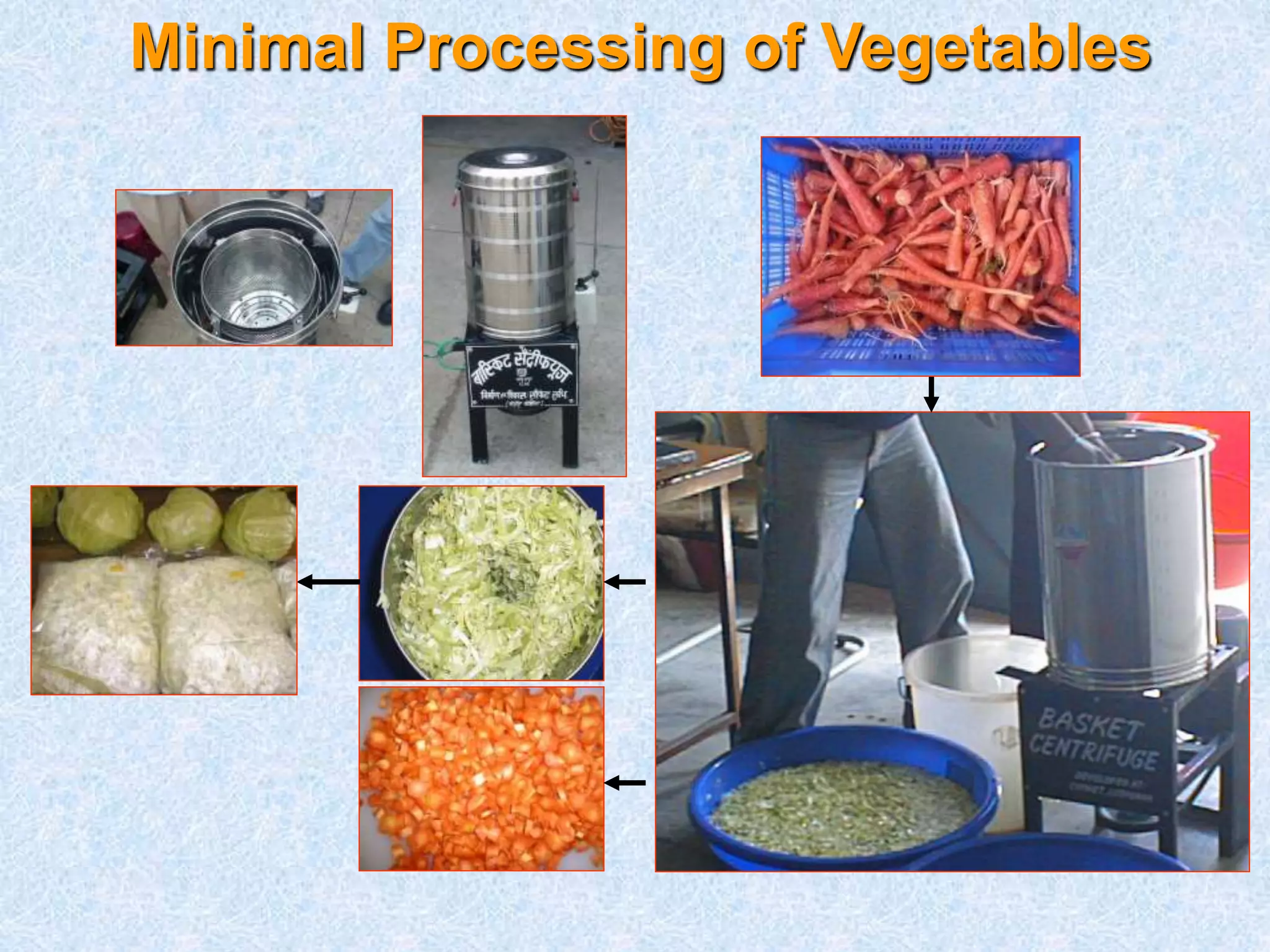

This document discusses various aspects of post-harvest technology and food processing in India. It notes that agriculture contributes 14.5% of India's GDP but post-harvest losses are estimated at Rs. 45,000 crores annually. It highlights opportunities for value addition through food processing and minimizing post-harvest losses using appropriate harvesting, handling, storage and processing techniques. Various technologies developed by CIPHET for grading, drying, packaging and value-added product development from fruits, vegetables and grains are also summarized.