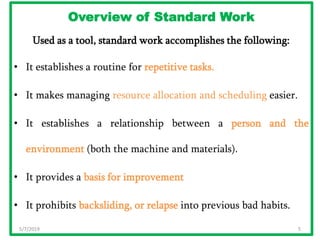

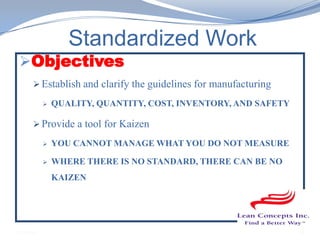

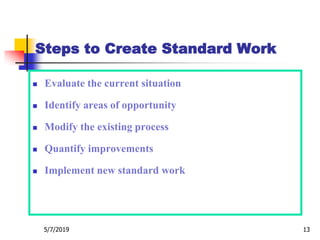

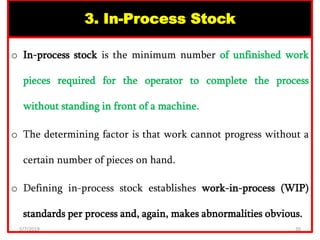

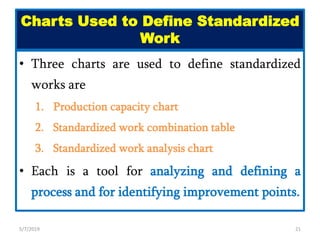

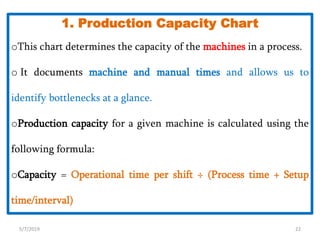

This document discusses standardized work and its importance in lean manufacturing. It begins by outlining the challenges of change that standardized work addresses. It then provides an overview of standardized work, noting that it establishes routines, aids in resource allocation, and provides a basis for improvement. The document outlines objectives of standardized work and some advantages and disadvantages. It discusses why standardized work is used, specifically to achieve process stability, clear process steps, organizational learning, problem identification, employee involvement, training, and continuous improvement. Several steps for creating standardized work are presented. Key elements of standardized work - takt time, work sequence, and standard work-in-process - are defined. Charts used to define standardized work like production capacity, standardized work combination