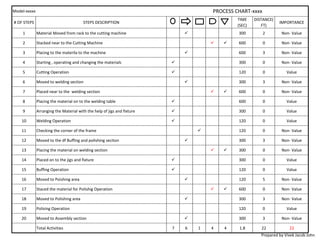

This document outlines the steps, time, distance, and importance of 20 steps in a manufacturing process. It includes cutting, welding, buffing, polishing, and assembly operations. The total time for all activities is 2400 seconds. Prepared by Vivek Jacob John, the document contains process charts and legends for cutting time, takt time, cycle time, and other production details.