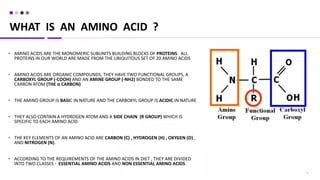

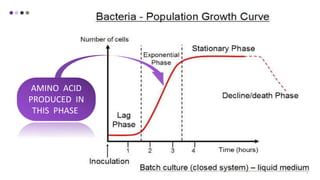

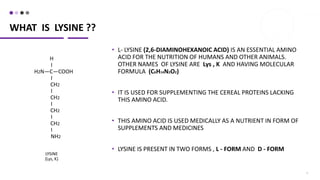

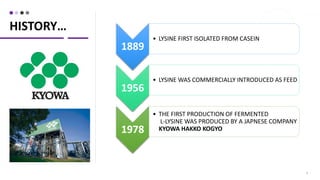

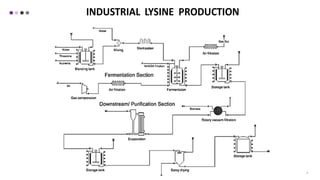

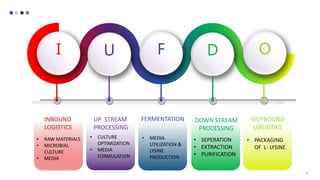

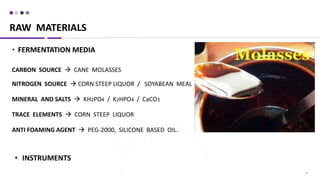

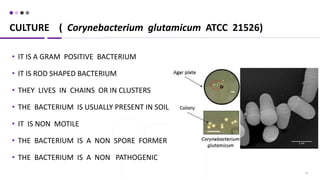

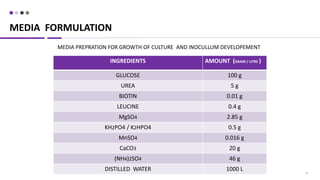

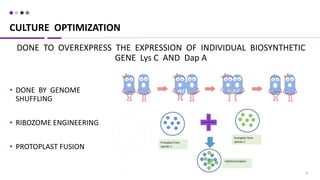

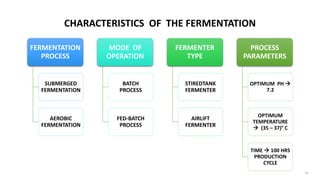

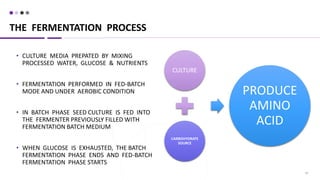

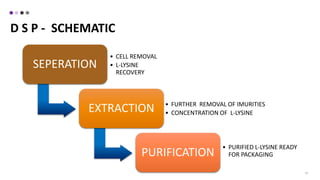

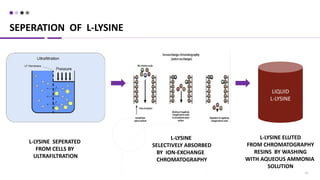

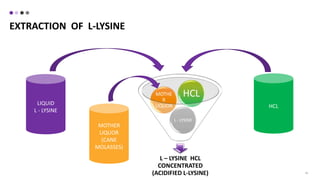

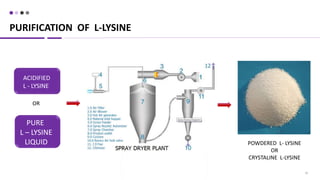

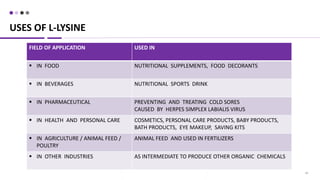

This document summarizes the production of the amino acid lysine through a fermentation process. It describes lysine and its importance as an essential amino acid. The fermentation process uses the microorganism Corynebacterium glutamicum and involves upstream processes like media formulation and culture optimization. Key downstream processes are separation, extraction and purification to produce purified lysine powder or crystals. The lysine produced has applications in food, pharmaceuticals, agriculture and other industries.