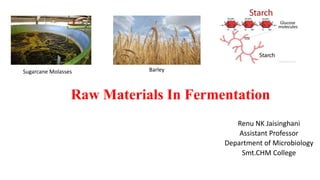

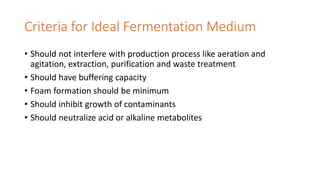

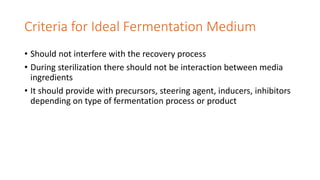

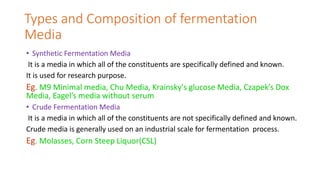

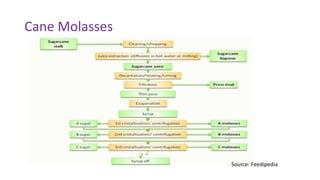

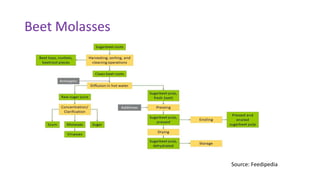

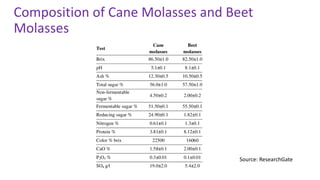

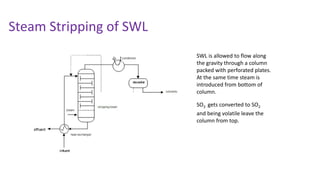

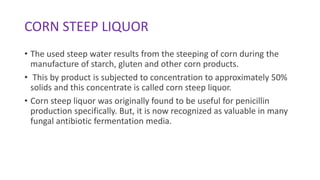

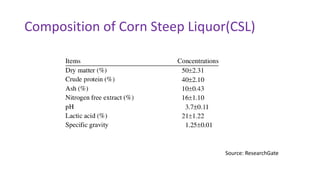

This document discusses raw materials used in fermentation processes. It covers various carbon sources like molasses, fruit juices, cheese whey, starches from cereals and tubers. It also discusses cellulosic materials like sulfite waste liquor, wood hydrolysates, and rice straw. Vegetable oils and hydrocarbons can also serve as carbon sources. Ideal fermentation media should satisfy the nutritional needs of microorganisms, support high product yields, use cheap and available raw materials, and not interfere with downstream processing. The type of raw material used depends on factors like cost, availability, and product being fermented.