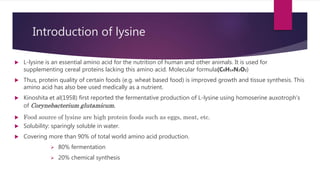

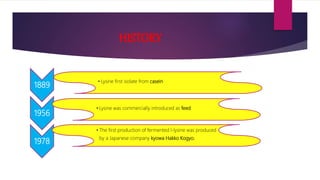

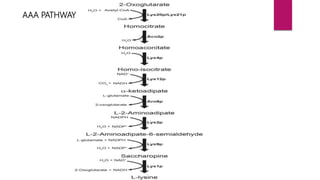

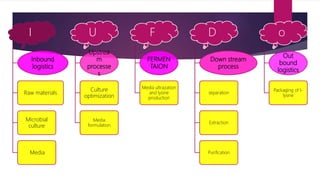

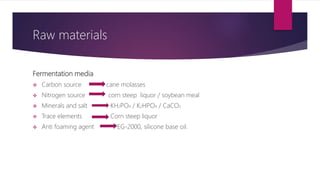

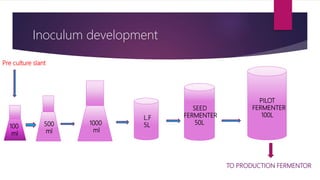

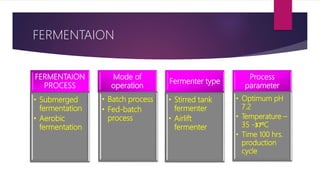

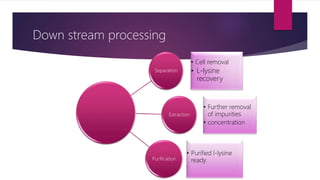

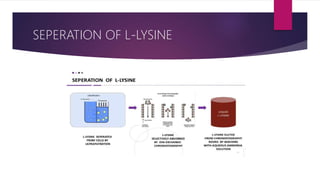

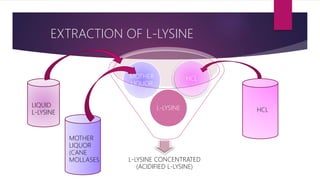

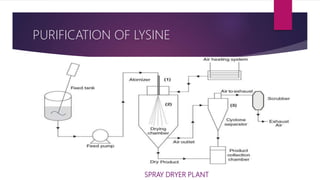

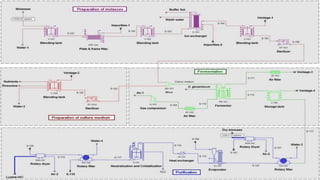

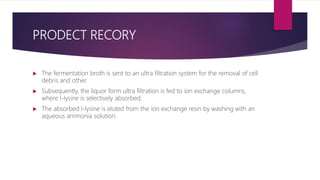

This document discusses the production of the essential amino acid L-lysine through fermentation. It begins by defining amino acids and classifying them as essential and non-essential. It then introduces L-lysine, describing its history of commercial production starting in 1956. The document outlines the two pathways for lysine biosynthesis and describes the industrial production process using Corynebacterium glutamicum. This involves upstream processes like culture optimization and media formulation and downstream processes such as separation, extraction and purification to produce purified L-lysine. Finally, applications of L-lysine in food, beverages, pharmaceuticals and other industries are listed.