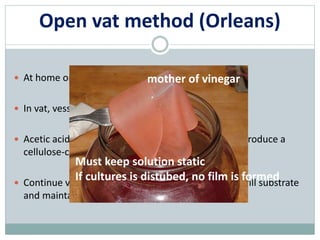

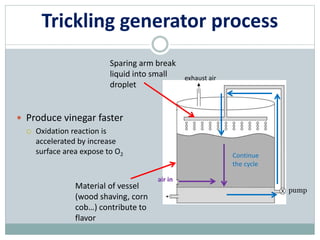

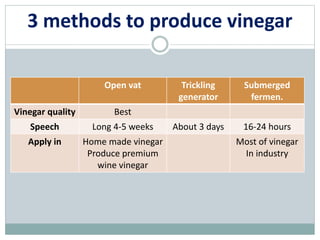

Vinegar is produced through a two-step fermentation process. First, sugars are fermented into ethanol through alcoholic fermentation. Then, acetic acid bacteria converts the ethanol into acetic acid, the main component of vinegar. There are three main methods for this second fermentation step - the open vat method, trickling generator process, and submerged fermentation. The open vat method is best for producing high quality vinegar but takes the longest, while submerged fermentation is fastest and most scalable for industrial production. After fermentation is complete, vinegar undergoes post-processing like filtration and pasteurization before use.

![What is vinegar?

Definition

[ethanol] < 0.5%

[acetic acid] ≥ 4%

pH 2-3.5

Vinegar ≠ chemical synthesis](https://image.slidesharecdn.com/vinegarproduction-181211000201/85/Vinegar-production-3-320.jpg)