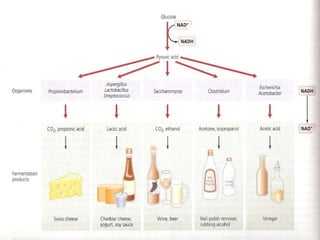

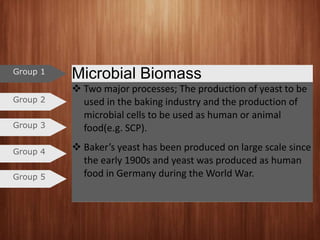

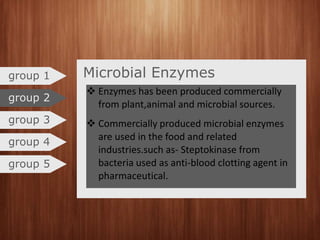

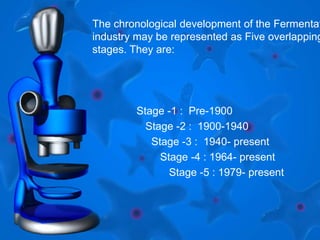

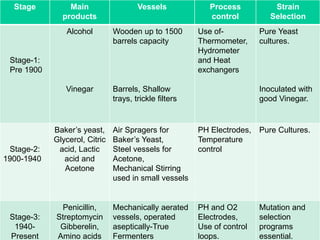

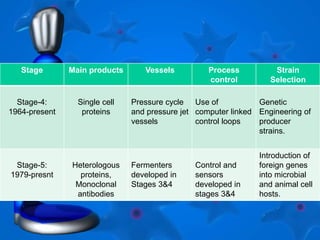

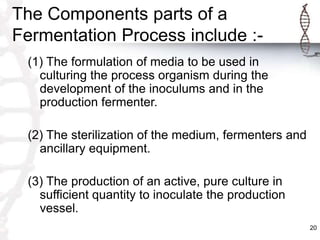

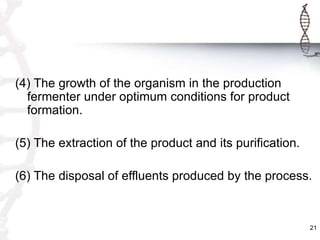

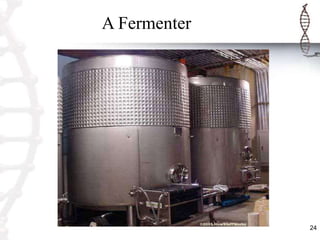

The document provides an overview of the fermentation process, defining it as the conversion of sugar to alcohol using yeast and encompassing a range of microbial and metabolic activities. It categorizes various types of commercially significant fermentation, including microbial biomass, enzymes, metabolites, recombinant products, and transformation processes, alongside a chronological development of the fermentation industry. Additionally, it outlines the essential components of fermentation processes, including media formulation, sterilization, culture production, and product extraction.