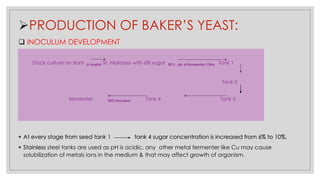

Baker's yeast is produced through a fermentation process using specific strains of Saccharomyces cerevisiae. The process involves developing an inoculum from stock cultures, then growing the yeast in large tanks through sequential fed-batch fermentations where sugar is added incrementally to promote respiration over fermentation. Final products are either compressed dry yeast (CDY) made by extruding and drying press cake, or activated dry yeast (ADY) made by further drying tiny yeast pellets which has better stability. Contaminants are controlled and final products are packaged for stability and viability during storage.