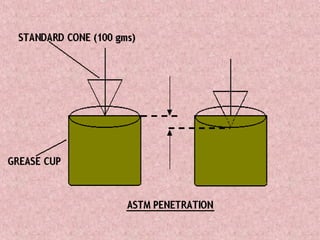

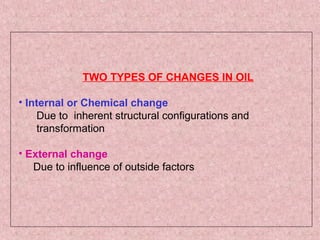

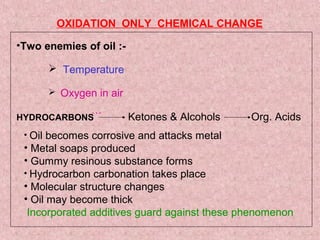

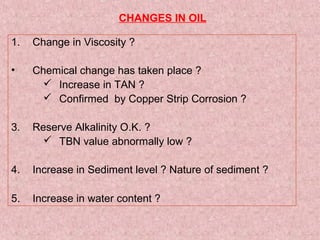

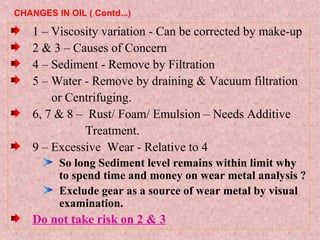

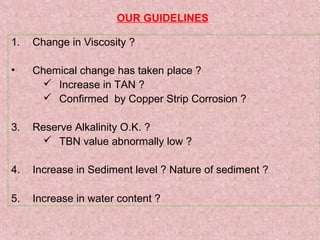

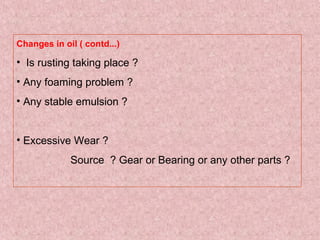

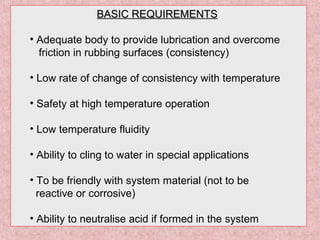

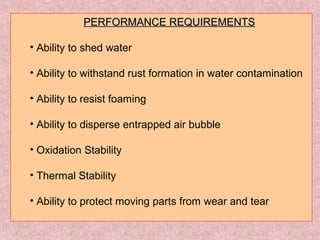

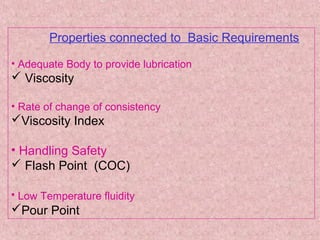

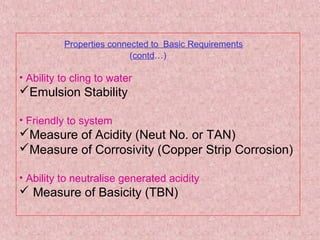

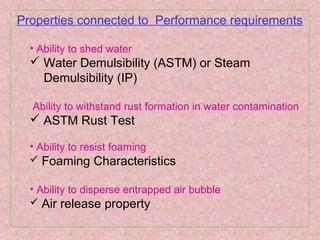

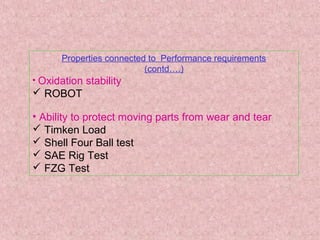

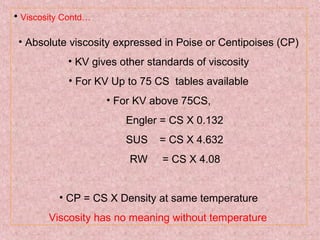

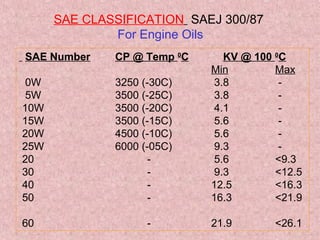

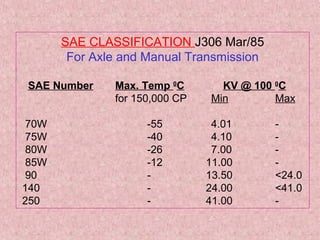

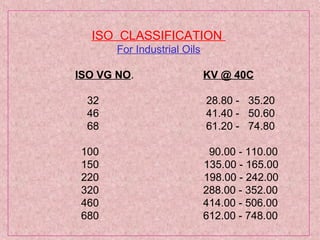

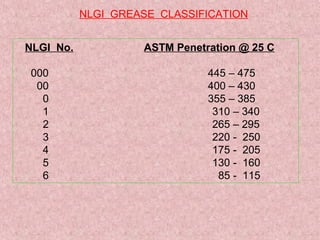

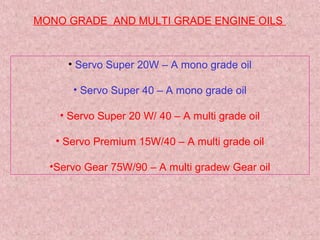

The document discusses lubricating oils and their properties. It asks questions about the basic requirements and performance requirements of lubricants as well as their related properties such as viscosity, viscosity index, flash point, pour point, etc. It also discusses SAE and ISO viscosity grades for engine oils and industrial lubricants. Greases are discussed including types of greases and their properties. Finally, it addresses the safety of using regenerated oil and outlines guidelines for determining when oil should be changed based on its condition rather than only operating hours.

![HOW TO CALCULATE VI 100 AND ABOVE ?

Formula gets altered

Data on 0 VI reference oil not needed

OILS KV 40C KV 100C

1. Test Oil U r

2. 100 VI reference H r

VI = [(antilog N) – 1] / 0.00715 +100

N = (log H – log U) /log r

Example

U=22.83, r = 5.05. From table wrt r=5.05, H=28.97

N = (log 28.97-log 22.83)/ log 5.05 = 0.14708

VI =(antilog 0.14708 –1/0.00715+100 = 156](https://image.slidesharecdn.com/lubricantsgeneralcomments-180525103041/85/Lubricants-general-comments-34-320.jpg)