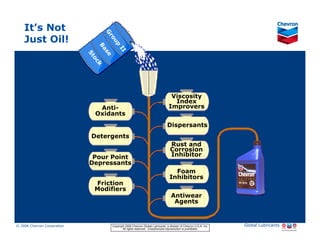

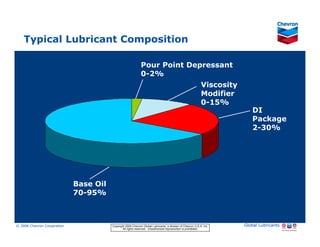

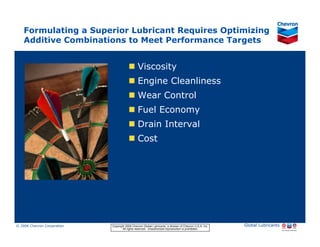

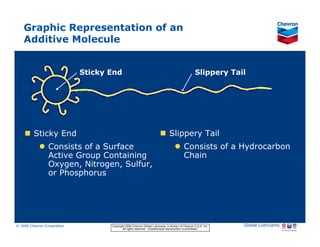

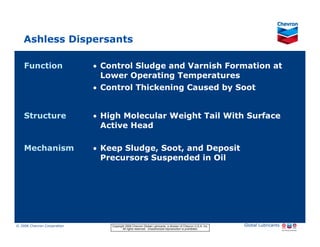

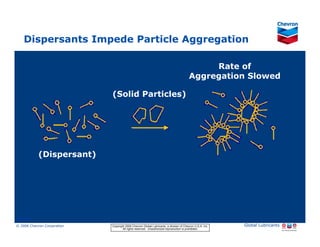

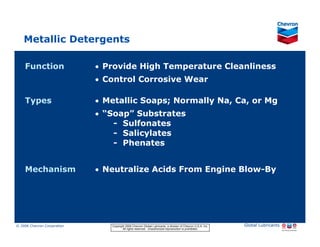

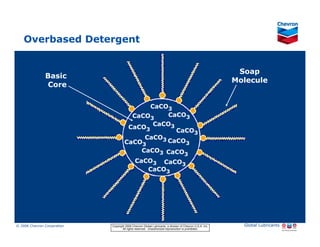

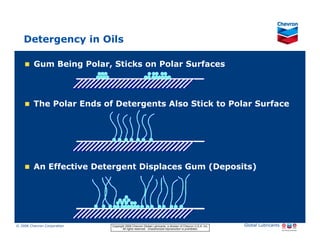

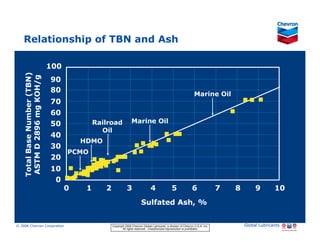

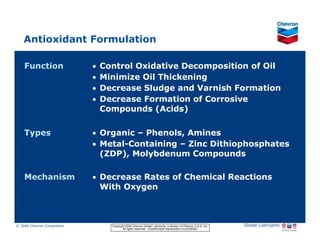

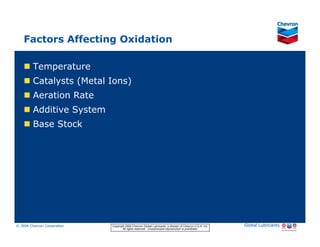

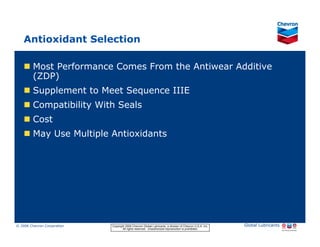

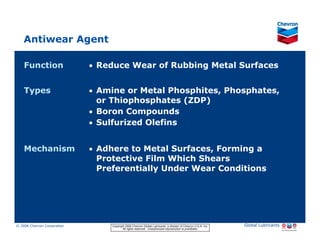

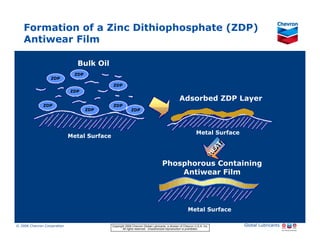

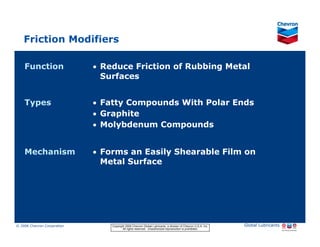

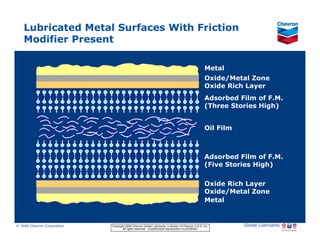

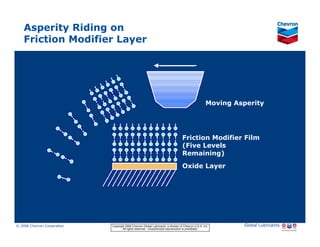

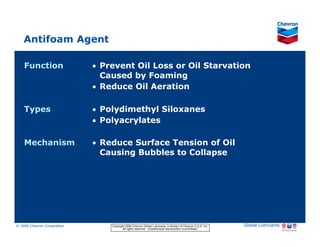

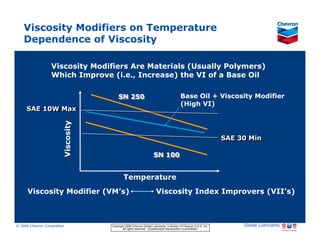

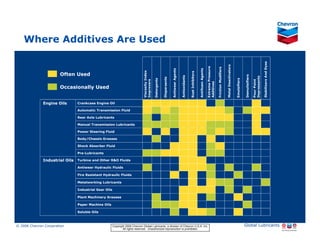

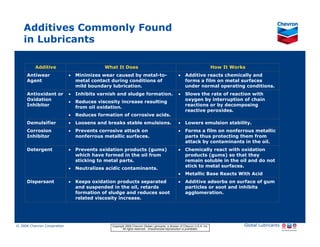

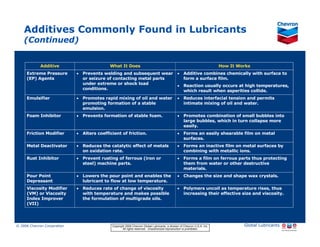

The document discusses lubricant additives that are important components in engine oils beyond just the base oil. It explains that additives like dispersants, detergents, antiwear agents, and others are formulated to optimize performance across attributes like engine cleanliness, wear control, and fuel economy. Graphs and diagrams show how these additive molecules interact with surfaces and particles to inhibit aggregation and neutralize acids from engine blow-by. Selecting the right combination and amounts of additives is necessary to balance performance factors.