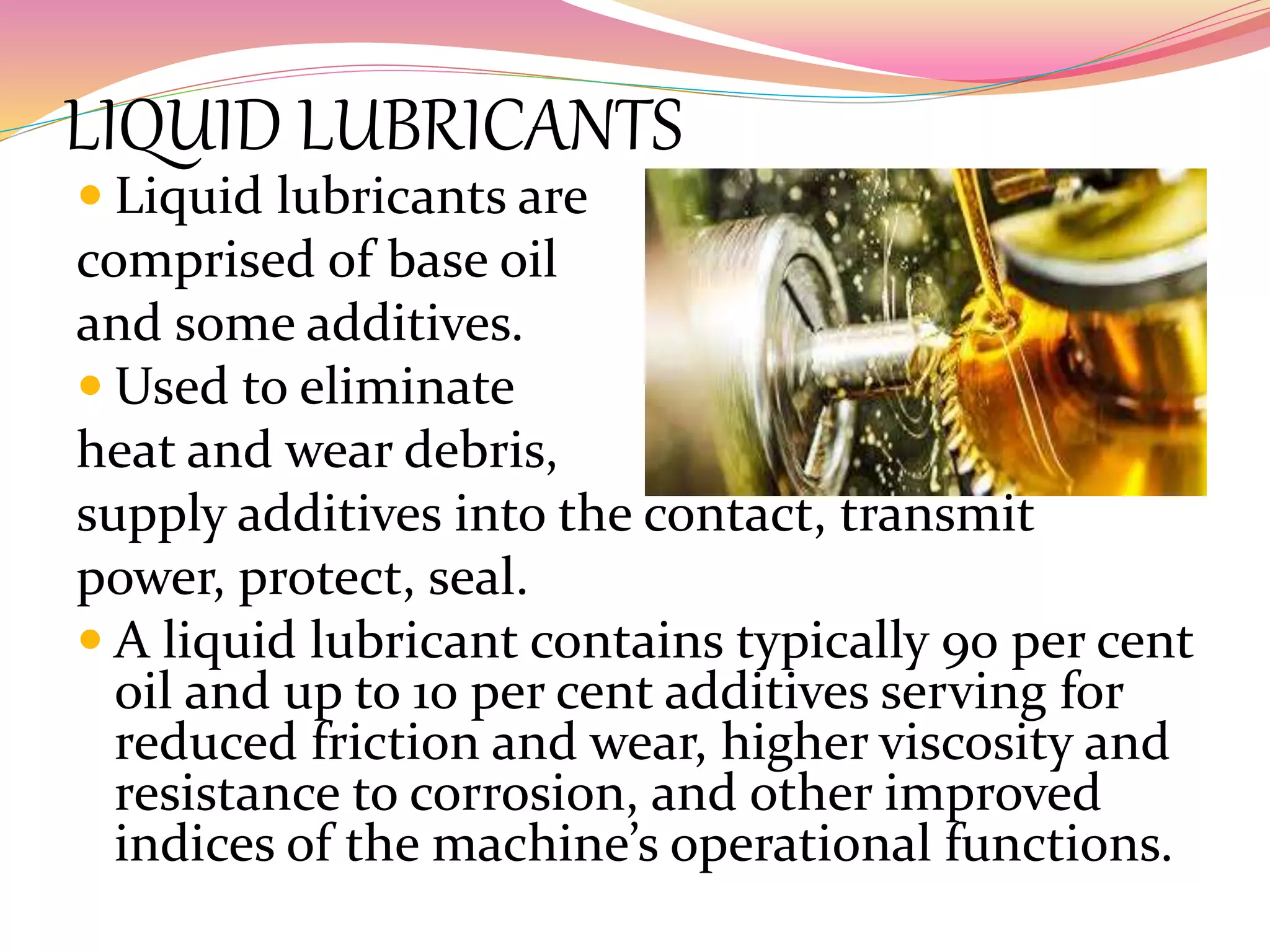

Lubricants are substances that reduce friction and wear between surfaces in contact. They are applied at interfaces to allow surfaces to move smoothly while also transferring heat and preventing overheating. Lubricants can be solid or liquid. Solid lubricants like graphite and molybdenum disulfide are used in extreme conditions and provide high load capacity but have higher friction. Liquid lubricants contain a base oil like mineral or vegetable oil along with additives and are more commonly used, providing continuous lubrication, filtration, and cooling of surfaces. Gaseous lubricants like nitrogen can also be used where film thickness is very small.