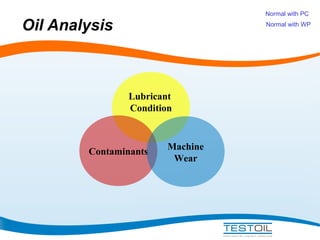

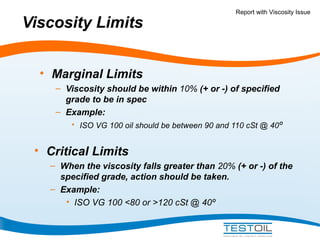

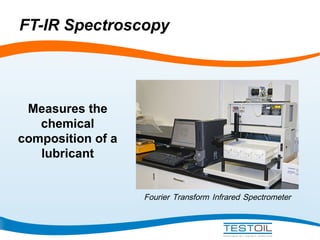

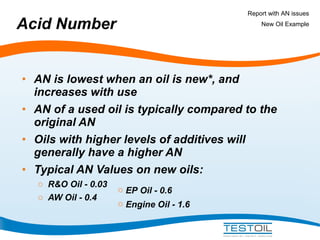

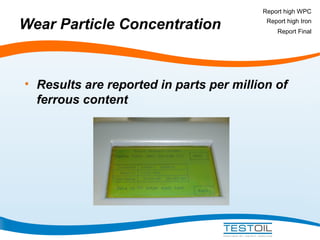

The document details a lubricant analysis report focusing on viscosity, wear metals, contaminants, and additives, highlighting how different factors affect the performance and longevity of lubricants. It specifies testing procedures and the importance of maintaining viscosity within prescribed limits, along with the analysis of wear particles and their sources. Additionally, it emphasizes the relevance of water content, oxidation, and acidic constituents as indicators of lubricant serviceability.