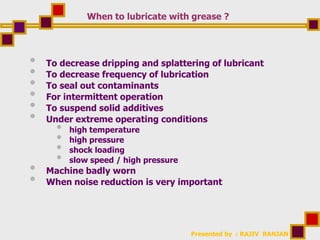

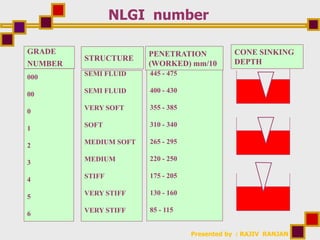

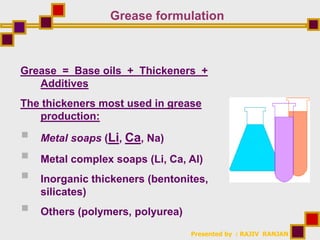

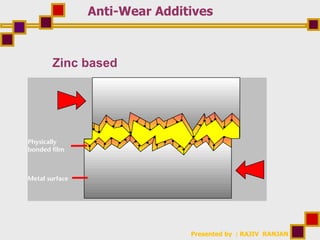

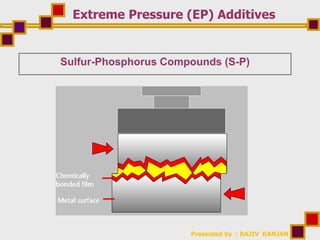

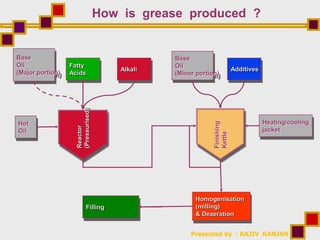

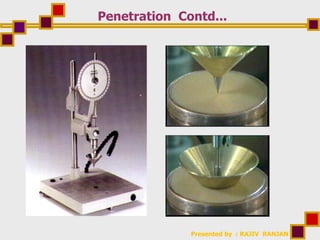

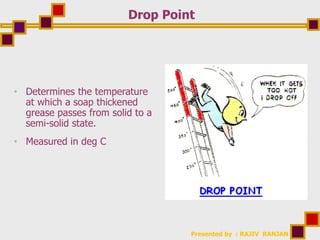

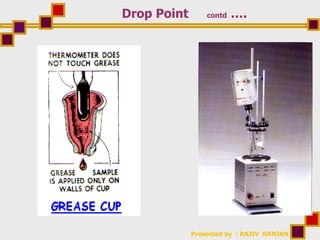

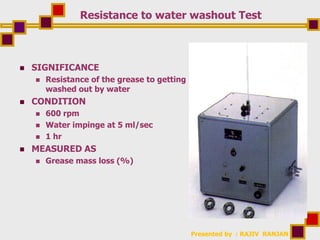

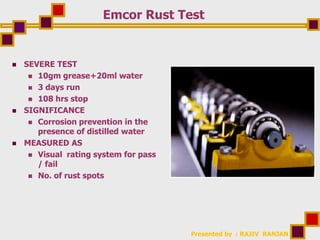

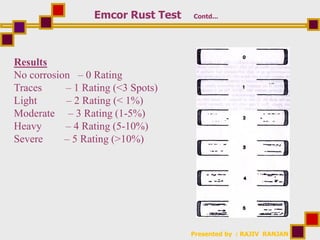

Greases are solid to semi-fluid products consisting of a fluid lubricant and a thickener. They typically contain 80-87% oil, 8-15% thickener, and 5% additives. Greases stay in place to seal and lubricate, unlike oils which can run away. Greases are used when intermittent lubrication is needed or operating conditions are extreme. Grease properties like penetration, drop point, and resistance to water washout are tested. Greases are formulated with base oils, thickeners like metal soaps, and performance additives. They are tested for properties like anti-wear protection and corrosion resistance. Proper grease storage and avoiding contamination are important.