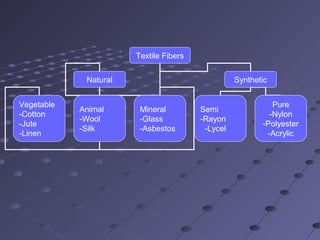

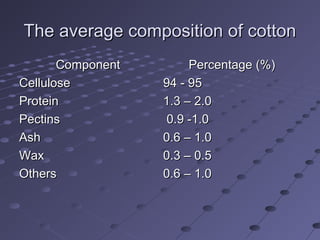

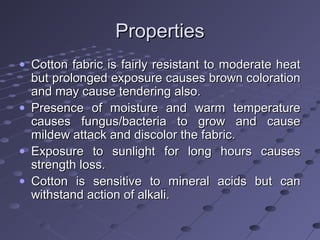

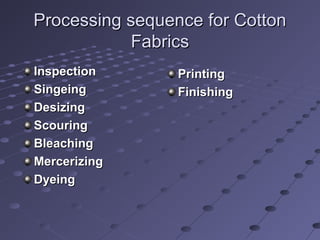

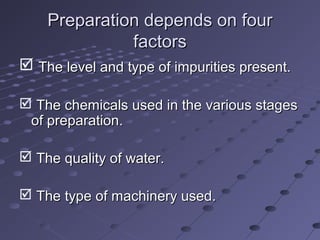

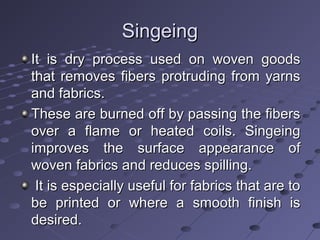

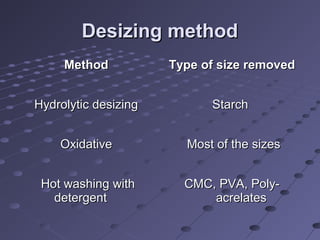

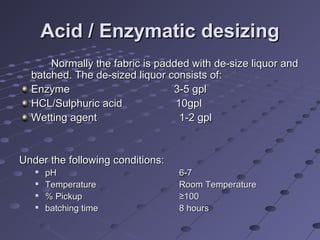

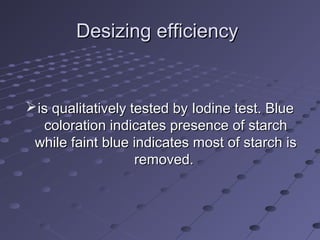

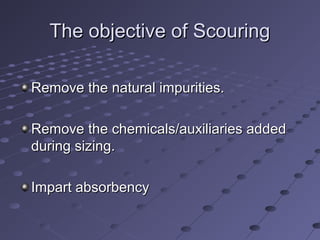

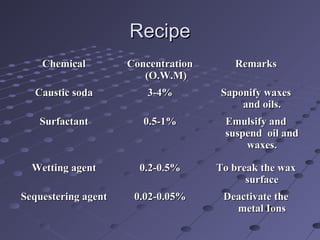

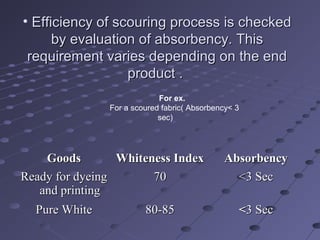

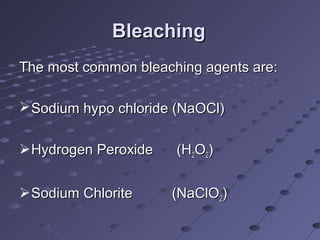

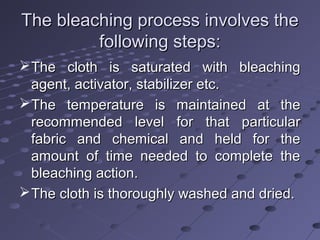

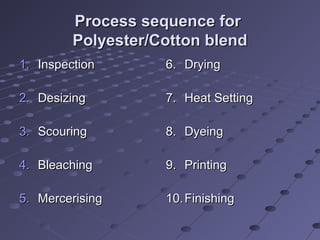

The document details the processing of cotton fabrics, including their composition, properties, and the steps involved in their preparation, dyeing, printing, and finishing. It outlines the average composition of cotton and discusses various processing techniques such as singeing, desizing, scouring, bleaching, and mercerization, highlighting their purposes and chemical involvement. Additionally, it provides insights into the effects of environmental factors and cleaning agents on cotton fabric durability and performance.