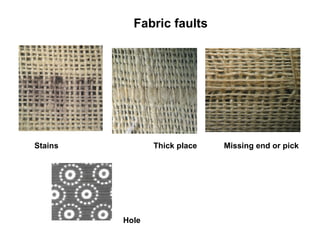

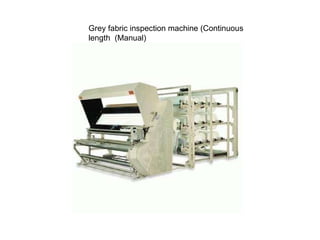

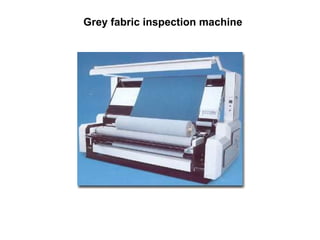

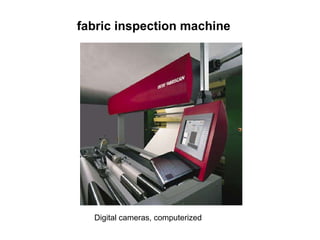

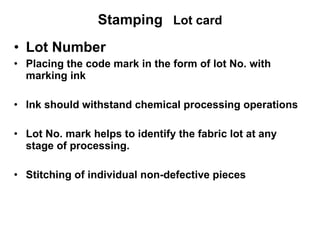

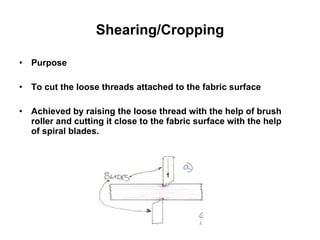

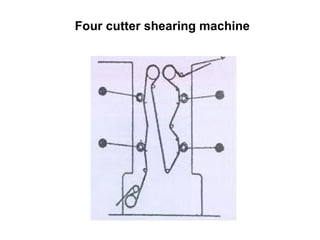

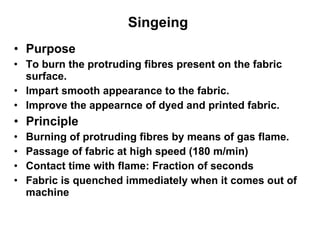

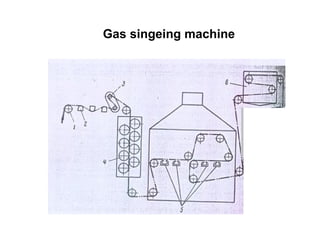

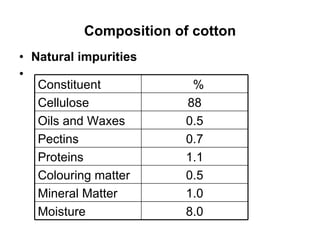

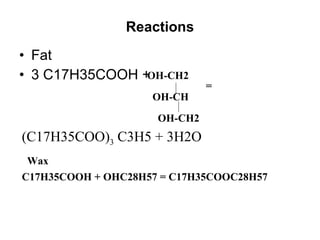

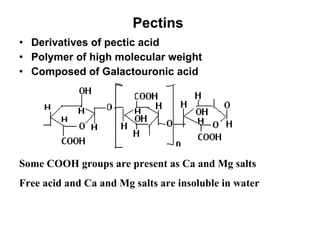

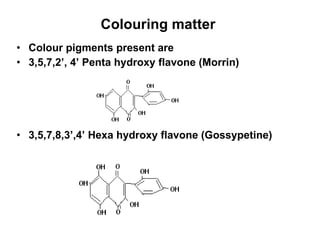

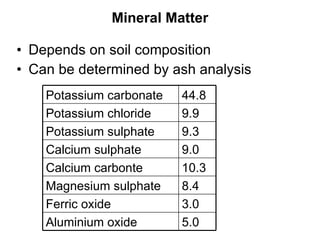

The document discusses various preparatory processes that cotton fabric undergoes before dyeing or other chemical processing. It describes how cotton contains natural impurities like fats, waxes, pectins, proteins and colouring matter that need to be removed. The preparatory processes involve mechanical operations like brushing to remove loose threads, shearing to cut attached threads, and singeing to burn protruding fibers. This is followed by inspection of grey fabric for defects and stamping with a lot number for identification during processing.