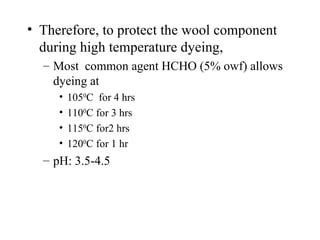

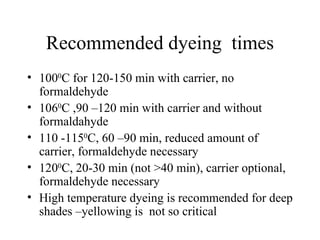

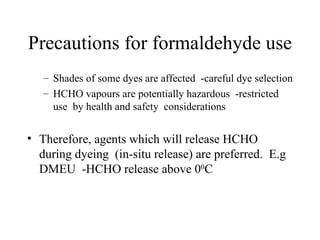

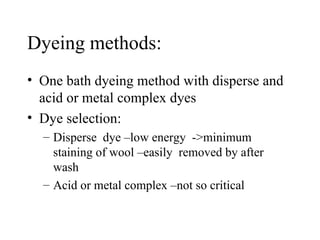

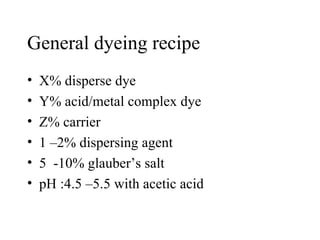

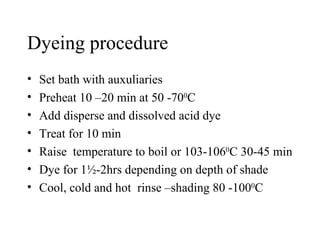

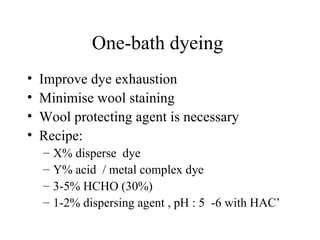

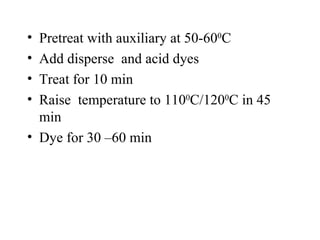

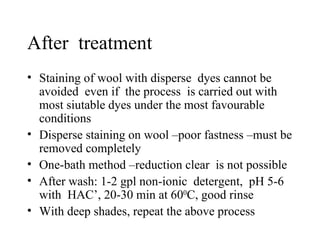

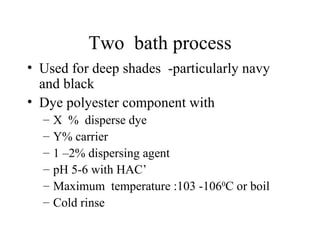

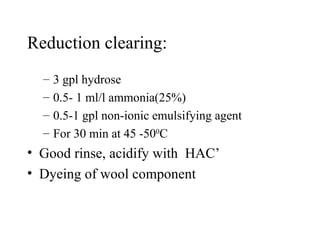

This document discusses methods for high temperature dyeing of wool-polyester blends to minimize damage to the wool. It recommends using formaldehyde or similar agents to protect the wool at temperatures up to 120°C. Specific dyeing times and temperatures are provided for different levels of wool protection. One-bath and two-bath dyeing methods are described that allow deep shades while reducing staining of the wool component. Post-treatment and troubleshooting steps are also outlined.