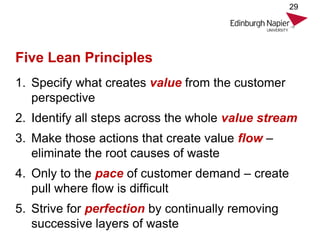

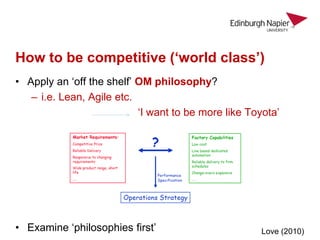

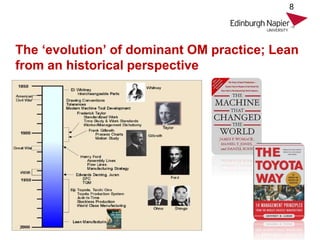

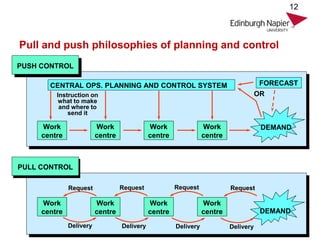

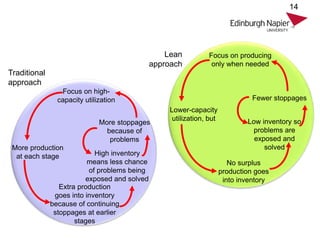

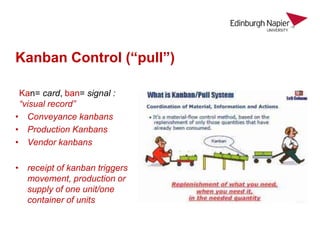

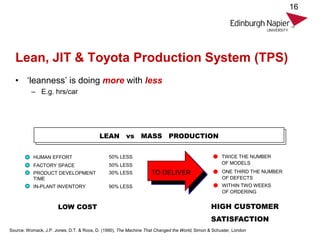

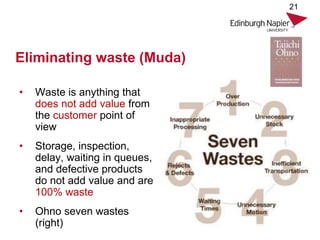

This document provides an overview of key concepts from a university course on lean thinking and operations management. It defines lean as eliminating waste through the involvement of all employees and continuous improvement. The Toyota Production System is discussed as a seminal example of lean. Key lean principles are reducing inventory, stopping problems at their source, producing only what is needed when it is needed, and continuously improving processes. Various lean tools like visual management, kanban systems, and setup reduction are also outlined. The document emphasizes that lean is a philosophy as well as a set of techniques for eliminating waste from operations.

![In “Toyota Production System: Beyond Large

Scale Production”, Taiichi Ohno says:

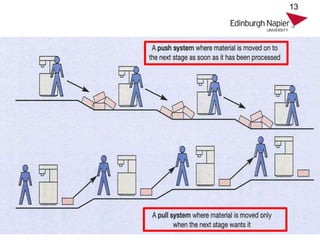

• [W]e frequently see people working ahead. Instead of waiting, the worker

works on the next job, so the waiting is hidden. If this situation is

repeated, inventory begins to accumulate at the end of the production line

or between lines. – page 59

• when we “hide the waiting”, then we create more waste – waste that can

be even more costly to the organization.

• We regard only work that is needed as real work, and define the rest as

waste. . . . we must make only the amount needed. – page 19

• I used to tell production workers one of my favourite stories about a boat

rowed by eight men. One rower might feel he is stronger than the next

and row twice as hard. This extra effort upsets the boat’s process and

moves it off course. – page 24

25](https://image.slidesharecdn.com/bhpounit3lean2015-151007224116-lva1-app6892/85/Lean-Thinking-25-320.jpg)