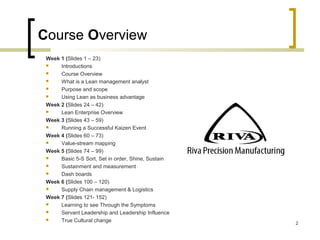

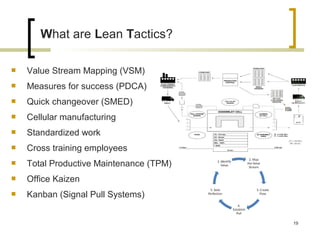

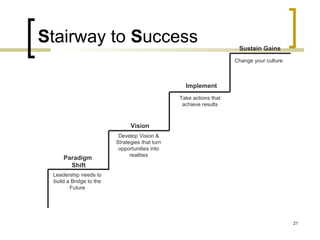

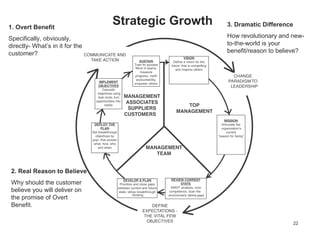

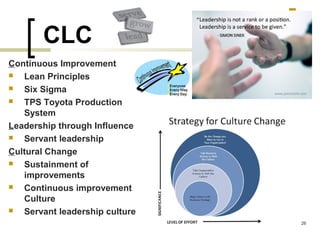

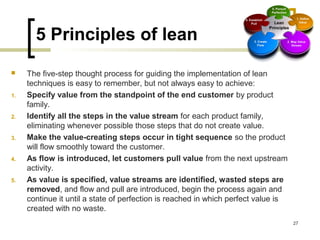

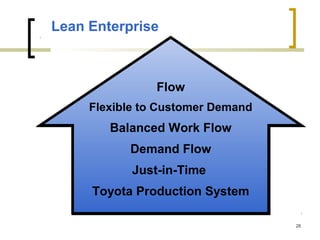

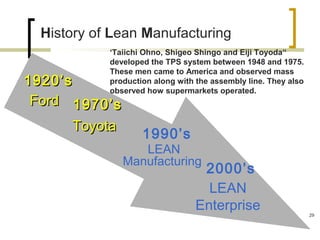

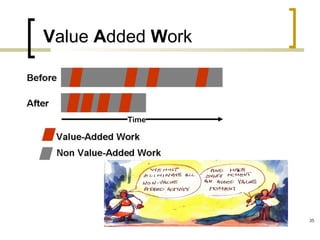

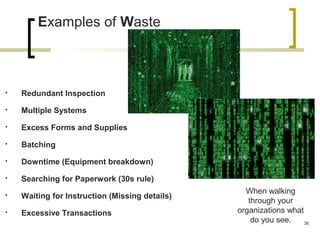

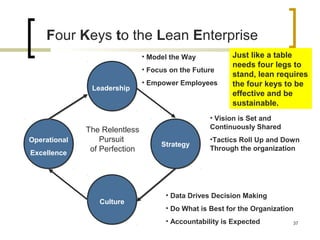

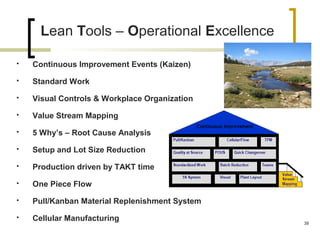

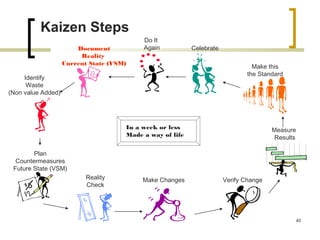

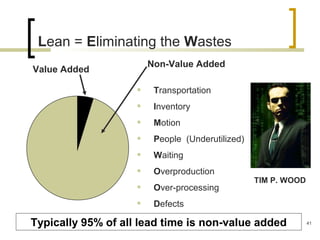

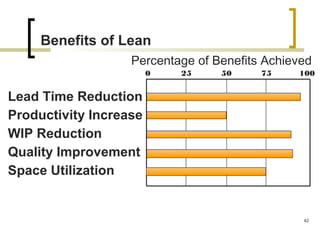

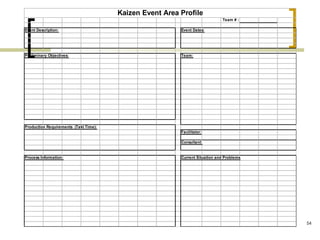

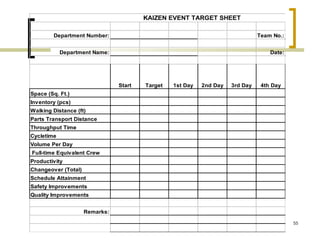

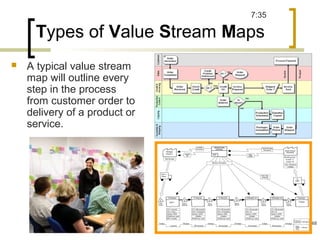

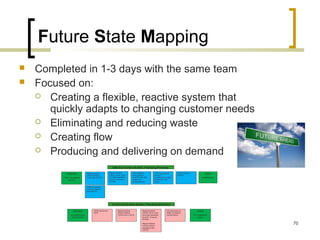

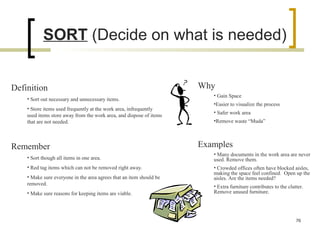

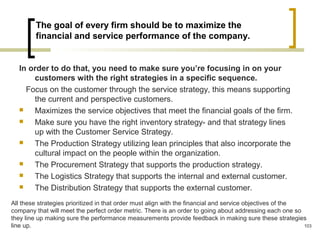

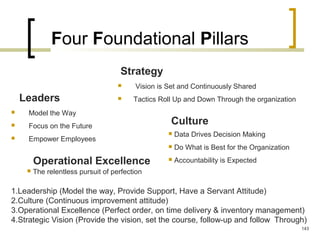

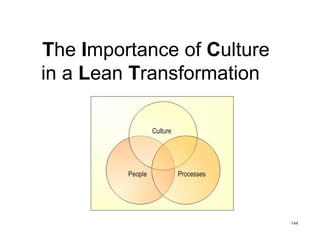

The document outlines a 7-week course on lean enterprise principles. Week 1 introduces lean management analysts and the course overview. Week 2 provides an overview of lean enterprise including its history, principles of lean, and defining value-added work. Additional weeks cover topics like running kaizen events, value stream mapping, 5S, supply chain management, and cultural change. Recommended readings are also included to further learning.