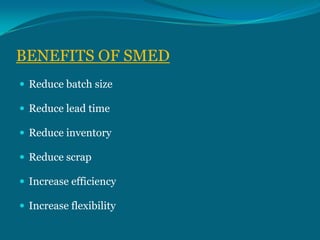

The document discusses lean manufacturing techniques including Single Minutes Exchange of Dies (SMED) and preventative maintenance. SMED aims to reduce changeover times to less than 10 minutes by separating internal and external changeover steps. It was developed in the 1950s-60s by Shigeo Shingo at Toyota to reduce bottlenecks. Preventative maintenance involves scheduled inspections and minor repairs to reduce unexpected breakdowns and increase equipment efficiency. It provides benefits like reducing downtime, costs, and safety issues compared to breakdown-based maintenance.