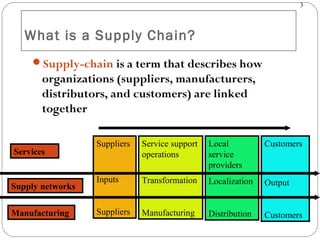

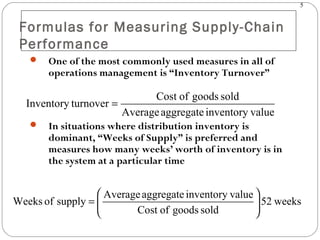

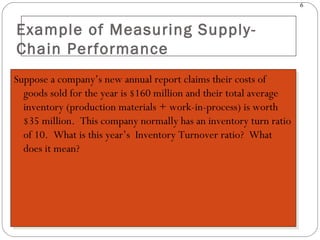

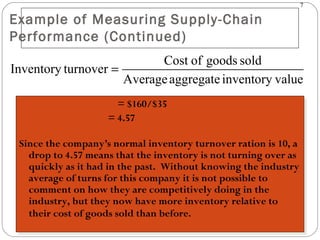

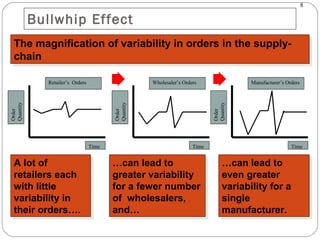

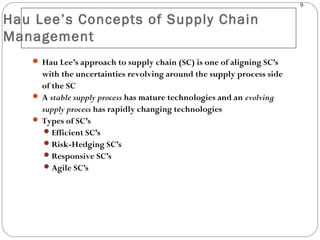

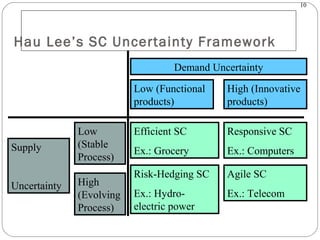

This document discusses key concepts in supply chain management including defining a supply chain and supply chain management. It discusses measuring supply chain performance using metrics like inventory turnover. The document also covers concepts like the bullwhip effect, Hau Lee's supply chain uncertainty framework, reasons for outsourcing, value density, and mass customization. Formulas are provided for calculating inventory turnover and weeks of supply. An example is given to demonstrate calculating inventory turnover.